2025 Guide: How to Choose the Best Bearing Tools for Your Projects

In the field of mechanical engineering and manufacturing, choosing the right Bearing Tools is paramount for ensuring the efficiency and longevity of machinery. A report by Research and Markets indicates that the global bearing market size is expected to surpass USD 140 billion by 2025, growing at a CAGR of 8.3% during the forecast period. This robust growth underscores the necessity for high-quality bearing tools that meet specific project requirements, reflecting the increasing complexity of modern machinery and equipment.

As technological advancements continue to evolve, professionals in various industries must navigate a plethora of options when selecting bearing tools that align with their specific applications. The right tools not only enhance operational performance but also significantly reduce maintenance costs and downtime. According to a study by Grand View Research, the demand for precision-engineered bearing tools is driven by both the automotive and aerospace sectors, which are pushing the boundaries of design and manufacturing processes.

In this guide, we will explore key factors to consider when selecting the best bearing tools for your projects. By understanding the intricacies of different bearings and their applications, along with emerging technology trends, you can make informed decisions that ultimately contribute to the success of your engineering endeavors.

Understanding Different Types of Bearing Tools Available in the Market

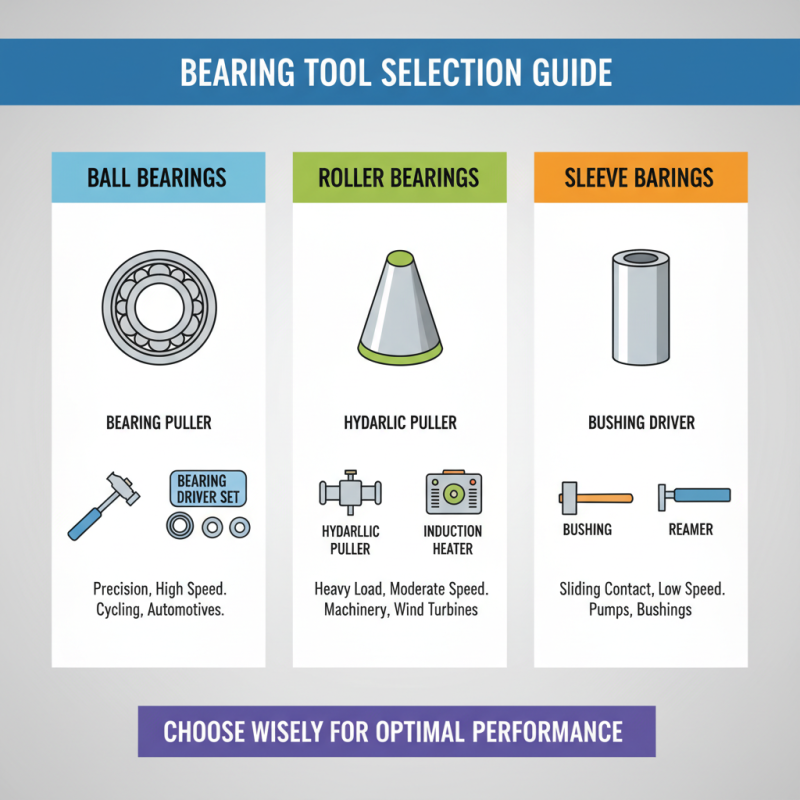

When embarking on a project that requires bearing tools, understanding the various types available in the market is crucial. Bearing tools come in different forms, each designed for specific applications, which can significantly affect the efficiency and effectiveness of your work.

Common categories include bearing pullers, which are essential for removing bearings without damaging them, and bearing installation tools that facilitate the precise fitting of bearings into assemblies. Additionally, specialty tools such as bearing heaters and hydraulic presses can simplify the tasks of both removal and installation, making them invaluable for more complex projects.

Another important consideration is the size and type of bearings you will be working with. Tools vary in capacity and design to accommodate different bearing sizes and styles, from miniature ball bearings to large industrial bearings. It’s important to select tools that not only match the physical dimensions of the bearings but also the specific mechanical requirements of your project. For instance, some tools are designed for press-fitting, while others may be more suited for drop-in installations. Understanding these distinctions will help you choose the right bearing tools, ensuring a smoother workflow and avoiding potential issues associated with improper installation or removal.

Key Factors to Consider When Selecting Bearing Tools for Your Project

When selecting bearing tools for your project, it is essential to consider the specific type of bearings you will be working with. Different bearings, such as ball bearings, roller bearings, or sleeve bearings, require distinct tools for installation and maintenance. Understanding the characteristics and applications of each type will help you choose tools that are compatible and effective. Additionally, ensure that the tools you select can handle the load and speed requirements of your project to maintain optimal performance and longevity.

Another key factor to consider is the material and construction of the bearing tools. High-quality materials such as steel or specialized alloys can significantly enhance the durability and reliability of your tools. Ensure that the tools are designed to withstand wear and tear during repetitive use, especially in demanding applications. Furthermore, ergonomic design elements can improve user comfort and reduce fatigue, making it easier to work on complex projects. Investing in the right tools not only enhances the efficiency of your work but also promotes safety and precision in your projects.

Comparing Quality and Durability of Leading Bearing Tools Brands

When selecting bearing tools for your projects, understanding the quality and durability of leading brands is essential. Each brand brings its unique engineering and manufacturing processes that can significantly impact performance and longevity. It is crucial to assess materials used, the precision of engineering, and any certifications or standards that the tools meet. Higher quality materials such as high-grade steel or advanced composites generally result in enhanced durability and performance. This, in turn, influences the tools' resistance to wear, corrosion, and other forms of degradation encountered during heavy usage.

In addition to material quality, the design and construction of bearing tools contribute tremendously to their effectiveness. Tools that incorporate ergonomic designs not only offer improved handling but also reduce strain during prolonged use, making them favorable for repetitive tasks. It's also worth exploring user reviews and expert opinions, as they provide insight into real-world performance. Comparing warranties and service agreements among different options can further guide your decision-making by highlighting the manufacturer's confidence in their product's durability. This thorough evaluation process ensures that the chosen bearing tools will meet the demands of your specific projects while maintaining longevity and reliability.

Essential Accessories and Add-ons for Enhanced Bearing Tool Performance

When selecting bearing tools for your projects, the right accessories and add-ons can significantly enhance performance and efficiency. According to the Machinery Industry Association's 2023 report, incorporating proper lubrication systems can improve the lifespan of bearing tools by up to 30%. High-quality greases and oils not only reduce friction but also help in maintaining optimal operating temperatures, ultimately leading to better performance.

Additionally, vibration analysis tools and monitoring systems have become essential in preventing premature bearing failures. The 2022 Bearing Management Report highlighted that about 40% of bearing failures occur due to inadequate monitoring. By investing in advanced diagnostic tools, professionals can identify and address issues before they escalate, ensuring smoother operation and reduced downtime for projects.

Tips: Always opt for ergonomic handling devices when working with bearing tools. This not only prevents physical strain but also enhances precision. Additionally, utilizing storage solutions designed for bearing tools can protect them from environmental factors, thereby prolonging their usefulness. With the right accessories and foresight, your projects can achieve unparalleled efficiency and durability.

Maintenance Tips for Prolonging the Life of Your Bearing Tools

When it comes to maintaining the life of your bearing tools, implementing a regular maintenance routine is essential. According to a report by the American Society of Mechanical Engineers (ASME), about 70% of bearing failures can be attributed to improper lubrication and inadequate maintenance practices. To optimize tool performance, it is crucial to regularly inspect bearings for any signs of wear or contaminants. A well-maintained bearing can significantly reduce friction and energy consumption, which not only extends the tool's lifespan but also enhances operational efficiency.

Another important aspect of maintenance is the proper storage of bearing tools. The National Lubricating Grease Institute (NLGI) emphasizes that bearings should be stored in a clean, dry environment to prevent rust and corrosion. Moreover, using nitrogen-filled packaging can further protect against moisture and contaminants. Regular cleaning of the tools, along with applying the right type of lubrication at the recommended intervals, can also prevent the accumulation of dirt and debris that might otherwise lead to premature failure. Studies show that a proactive maintenance strategy can increase the lifespan of bearing tools by up to 50%, making routine checks and proper care essential practices for any project.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us