What is an Angular Bearing and How Does it Work in Mechanical Applications

Angular bearings play a pivotal role in various mechanical applications, providing crucial support and facilitating smooth rotational movements. According to the Global Bearings Market Report 2023, the demand for bearings, particularly angular bearings, is projected to grow at a CAGR of 5.6% through 2030, reflecting their integral function in industrial machinery, automotive systems, and aerospace engineering. As industries increasingly rely on precision engineering for enhanced performance, the significance of angular bearings cannot be overstated.

Renowned industry expert Dr. Emily Carter, a leading mechanical engineer at the Institute of Mechanical and Aerospace Engineering, emphasizes the importance of angular bearings: “In applications where alignment and load distribution are critical, angular bearings are essential for optimal performance and durability.” This statement underscores the necessity of understanding how angular bearings function and their application in reducing friction while supporting axial and radial loads. As the market evolves, integrating emerging technologies with traditional angular bearing designs will be key to meeting the growing demands of mechanical systems.

Definition of Angular Bearings and Their Purpose in Mechanics

Angular bearings are specialized bearing types that allow for angular rotation between parts, playing a pivotal role in various mechanical applications. These bearings are engineered to support axial loads, which are forces pushing parallel to the shaft, in addition to radial loads, which act perpendicular to the shaft. According to a 2021 report from the Global Bearings Market, angular bearings represent a significant segment, with their demand projected to grow at an annual rate of approximately 5.2% over the next five years, driven by advancements in automotive and aerospace technologies.

The primary purpose of angular bearings in mechanics is to facilitate smooth rotational movement while minimizing friction and wear. They are essential in assemblies where a combination of axial and radial loads occurs, such as in gearboxes, machine tools, and conveyor systems. Their distinct design, often incorporating a contact angle, enables them to handle loads effectively while providing durability and operational efficiency. Industry data indicates that the increased application of robotics and automation has further amplified the reliance on angular bearings, indicating their critical role in enhancing machine performance and reliability.

Types of Angular Bearings Used in Various Applications

Angular bearings are specialized components designed to handle both radial and axial loads, making them essential in various mechanical applications.

One common type is the single-row angular contact bearing, which provides a high degree of axial load capacity while maintaining a compact design. This type is often used in spindle applications, where high precision and rigidity are required. Another variant is the double-row angular contact bearing, which is designed for applications with higher load capacities and is ideal for heavy machinery and automotive uses.

These bearings can support combined loads from different directions, enhancing their durability and operational efficiency.

In addition, there are angular bearings designed for extreme conditions, such as those faced in aerospace or marine environments. These bearings are often made with materials that can withstand corrosion, high temperatures, and heavy shock loads, ensuring reliability in demanding applications. Each type of angular bearing is engineered to deliver optimal performance, tailored to the unique requirements of the equipment in which they are used.

Principles of Operation for Angular Bearings

Angular bearings are designed to support radial and axial loads simultaneously, making them essential in various mechanical applications. The principles of operation for angular bearings revolve around their unique geometrical shape, typically featuring inner and outer rings with angled grooves. This design allows the balls or rolling elements to be positioned at a specific angle, enabling them to accommodate forces from different directions efficiently. When an axial load is applied, the angle of the bearing helps distribute the load evenly, reducing wear and extending the bearing’s lifespan.

In operation, the orientation of the angular bearing determines its load capacity and performance characteristics. The configuration can be single-row or multi-row, depending on the application's requirements. Single-row angular bearings can support axial loads in one direction, while pairs of bearings are often used to handle loads from both directions, enhancing stability and performance. The precision in the design and manufacturing of these bearings ensures smooth rotation and minimal friction, which is critical for high-speed applications and heavy machinery. Understanding these principles is vital for selecting the right type of angular bearing for specific mechanical tasks, ensuring optimal efficiency and reliability in operation.

What is an Angular Bearing and How Does it Work in Mechanical Applications - Principles of Operation for Angular Bearings

| Dimension |

Value |

Unit |

Description |

| Inner Diameter |

20 |

mm |

The diameter of the hole through the center of the bearing. |

| Outer Diameter |

42 |

mm |

The external diameter of the bearing. |

| Width |

12 |

mm |

The thickness of the bearing. |

| Load Capacity |

1500 |

N |

The maximum load the bearing can support. |

| Speed Rating |

4000 |

RPM |

The maximum rotational speed the bearing can handle. |

| Operating Temperature |

-20 to 120 |

°C |

The temperature range in which the bearing can operate effectively. |

Installation and Maintenance of Angular Bearings

Angular bearings are vital components in various mechanical applications, providing rotational support where shaft misalignment is present. Proper installation and maintenance practices are crucial to ensuring their longevity and efficiency. According to a study published in the Journal of Mechanical Engineering, improperly installed bearings can lead to a reduction in the lifespan of the equipment by up to 40%, resulting in increased costs for replacement and downtime. Therefore, following the manufacturer's guidelines during installation, including correct alignment and appropriate torque specifications, is essential to avoid premature failure.

Regular maintenance is equally important for the performance of angular bearings. A report from the International Journal of Industrial Maintenance suggests that nearly 30% of bearing failures can be attributed to inadequate lubrication and contamination. It is recommended to inspect the bearings periodically, checking for signs of wear or misalignment as well as ensuring a clean lubrication environment. Utilizing advanced monitoring technologies such as vibration analysis can provide real-time data regarding bearing health, allowing for timely interventions before catastrophic failures occur. By adhering to recommended maintenance schedules and practices, the operational efficiency and service life of angular bearings can be significantly enhanced, ultimately contributing to more reliable mechanical systems.

Angular Bearings Performance in Various Mechanical Applications

This bar chart illustrates the performance rating of angular bearings under various load conditions. As seen, their effectiveness decreases as the load increases, highlighting the importance of selecting the appropriate bearing type for specific applications.

Common Applications of Angular Bearings in Machinery

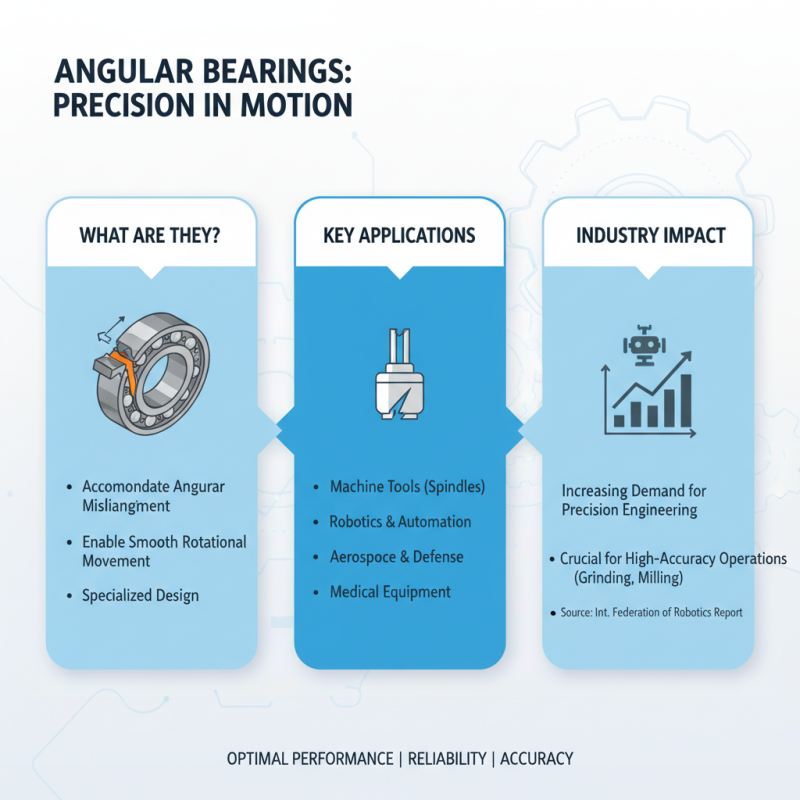

Angular bearings play a crucial role in various mechanical applications, particularly in industries that rely on precise movement and positioning. These specialized bearings are designed to accommodate angular misalignments and enable smooth rotational movement. One of their most common applications is found in machine tools, where they support spindle assemblies and ensure high accuracy during operations like grinding and milling. A report by the International Federation of Robotics highlighted that the demand for precision engineering in machinery is increasing, leading to greater reliance on angular bearings for optimal performance.

In addition to machine tools, angular bearings are prominently used in robotics and automation systems. They provide the necessary support and stability for robotic arms, allowing for intricate movements that require both precision and flexibility. According to a market analysis by Transparency Market Research, the robotics sector is expected to grow significantly, emphasizing the need for efficient and reliable components like angular bearings to enhance productivity in manufacturing processes.

Tips: When selecting angular bearings for specific applications, it is essential to consider factors such as load ratings, speed capability, and environmental conditions. Ensuring compatibility with the machinery can greatly improve performance and lifespan. Regular maintenance and lubrication can also enhance efficiency and reduce wear, ultimately leading to lower operational costs and increased machinery longevity.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us