Understanding the Importance of Angular Bearings in Modern Machinery

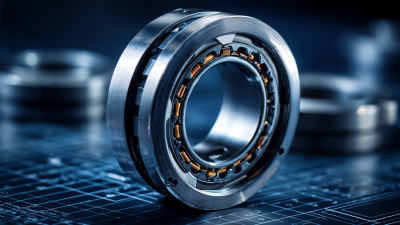

In modern machinery, the significance of Angular Bearings cannot be overstated.

These specially designed bearings play a crucial role in allowing precise axial and radial load support, which is essential for the efficient performance of various equipment.

Angular Bearings are pivotal in facilitating smooth rotational motion while minimizing friction and wear, leading to enhanced operational longevity.

As industries continue to evolve and demand higher efficiency and reliability from their machinery, understanding the intricacies of Angular Bearings becomes increasingly important.

This article aims to provide valuable insights and tips on utilizing Angular Bearings effectively, ensuring that professionals and enthusiasts alike can make informed decisions that contribute to optimal machine performance.

Through a comprehensive exploration of key aspects associated with Angular Bearings, readers will gain a deeper appreciation for their vital role in the mechanics of contemporary engineering applications.

Significance of Angular Bearings in Enhancing Machine Performance

Angular bearings play a critical role in enhancing the performance of modern machinery across various industries. These specialized bearings are designed to accommodate both radial and axial loads, making them indispensable in applications that require high precision and reliability. According to a report by Lucintel, the global bearing market is projected to reach $92 billion by 2025, with angular contact bearings driving significant growth due to their efficiency in high-speed operations.

Incorporating angular bearings into machinery not only improves load distribution but also minimizes friction, leading to longer service life and reduced maintenance costs. A study from the American Society of Mechanical Engineers (ASME) suggests that the right bearing selection can enhance machine efficiency by up to 30%. This efficiency translates into lower energy consumption, which is vital in today's eco-conscious industrial landscape.

**Tips:** When choosing angular bearings for your machinery, consider factors such as load capacity, speed ratings, and the operating environment. Regular maintenance checks can also significantly extend the life of these components. Ensuring proper alignment during installation is crucial to prevent premature wear and tear.

Key Features of Angular Bearings: What You Need to Know

Angular bearings are essential components in modern machinery, specifically designed to handle both radial and axial loads. Their unique angular arrangement allows these bearings to provide superior performance in applications requiring precision and stability. One of the key features of angular bearings is their ability to support high-speed operations, making them ideal for use in automotive wheel assemblies and high-performance machinery. In these applications, specific bearing types, such as ball and tapered roller bearings, play a crucial role in enhancing the efficiency and reliability of the overall system.

Moreover, recent advances in bearing technology, particularly in the realm of ceramic angular contact ball bearings, have further improved their functionality. These bearings exhibit excellent wear resistance and reduced friction, contributing to longer lifespan and improved performance under high-speed operations, such as in wind turbine main shafts. As the global demand for high-performance machinery continues to rise, understanding the critical features and applications of angular bearings becomes increasingly important for engineers and manufacturers alike, ensuring optimal design and operational efficiency.

Understanding the Importance of Angular Bearings in Modern Machinery

| Feature |

Description |

Application |

Benefits |

| Load Capacity |

Angular bearings can support both radial and axial loads. |

Machine tools, automotive applications |

Increased reliability under heavy load conditions. |

| Angular Contact |

Designed to handle high-speed applications and thrust loads. |

Electric motors, pumps |

Enhanced performance and reduced friction. |

| Material Options |

Available in various materials like steel, ceramic, and plastic. |

Heavy machinery, aerospace |

Corrosion resistance and high-temperature performance. |

| Precision |

High precision manufacturing for improved accuracy. |

Robotics, CNC machinery |

Improved efficiency and quality in operations. |

| Maintenance |

Requires specific maintenance practices for longevity. |

Industrial equipment |

Reduced downtime and increased lifespan of equipment. |

Comparison of Angular Bearings vs. Other Bearing Types

When examining the realm of machinery, understanding the differences between angular bearings and other types of bearings is crucial. Angular bearings, designed to accommodate both radial and axial loads, offer distinct advantages in applications requiring precision and stability. Unlike standard deep-groove ball bearings, angular bearings operate with a specific contact angle, which allows for higher load capacities and improved rigidity. This makes them ideal for use in high-speed machinery, robotics, and precision engineering.

When comparing angular bearings to other bearing types like roller bearings, one notable aspect is their ability to handle axial forces in both directions. While roller bearings are typically favored for heavy-load applications due to their larger surface area, they often lack the precision required for intricate machinery. It's essential to consider the working environment and load conditions when choosing between these options.

**Tip:** Always consult the manufacturer's specifications for load ratings and operational limits when selecting bearings for your machinery. Ensuring compatibility with your machinery's design can significantly extend the lifespan and efficiency of operation. Additionally, regular maintenance and lubrication are key to ensuring optimal performance, irrespective of the bearing type you choose.

Importance of Angular Bearings vs. Other Bearing Types

Maintenance Tips for Maximizing Angular Bearing Longevity

Proper maintenance of angular bearings is crucial for ensuring their longevity and optimal performance in modern machinery. According to a report by the Bearing Manufacturers Association, approximately 30% of bearing failures can be attributed to improper lubrication practices. Regularly maintaining the correct lubricant levels is essential, as inconsistent lubrication can lead to increased friction and premature wear. Implementing a routine lubrication schedule, using high-quality lubricants specific to the application, can significantly enhance the durability of angular bearings.

Another key aspect of maintenance is monitoring operating temperatures and environment conditions. A study by the American Society of Mechanical Engineers highlights that bearings operating at temperatures above their recommended limits can experience a reduction in lifespan by up to 50%. Keeping angular bearings clean and free of contaminants can also prevent damage. Utilizing protective seals and regular inspection for signs of wear or corrosion will foster a reliable operational environment, ultimately maximizing the performance and longevity of angular bearings in machinery.

Innovative Applications of Angular Bearings in Modern Industry

Angular bearings play a transformative role in modern industry, offering innovative solutions that cater to the evolving needs of various applications. In particular, their use in wind turbine main shafts reflects their growing significance as turbine rotor sizes increase. Research highlights that the reliability of these bearings is crucial to the operational efficiency of turbines, especially given the emphasis on maximizing energy output. As turbine designs evolve, rolling element bearings are being refined to enhance their performance under high loads and challenging conditions, showcasing how academic advancements lead to practical industrial applications.

Moreover, the integration of angular bearings in newer technologies, such as humanoid robots, marks a significant milestone in mechanical engineering. Recent exhibitions have underscored their importance in creating sophisticated machinery that mimics human movement. These bearings contribute to the precision and reliability required in robotic joints, thus supporting advancements in automation. Additionally, innovations in wheel bearings are enhancing vehicular performance, particularly with the introduction of encapsulated designs that promise improved durability. As industries continue to prioritize efficiency, the role of angular bearings becomes increasingly indispensable in both traditional and emerging sectors.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us