Why Automotive Bearings Are Essential for Vehicle Performance and Safety

Automotive Bearings play a critical role in the overall performance and safety of vehicles, acting as essential components that reduce friction and facilitate smooth motion between moving parts. According to renowned automotive engineering expert Dr. Emily Carter, "The efficiency and reliability of a vehicle largely hinge on the quality of its bearings, making them indispensable to modern automotive design." This statement underscores the vital importance of Automotive Bearings in the intricate machinery of today's vehicles.

In the automotive industry, the choice and maintenance of bearings can significantly impact fuel efficiency, handling, and ultimately, driver safety. As vehicles become more complex with advancements in technology, the demand for high-performance Automotive Bearings continues to grow. The evolution of bearing materials and designs reflects a commitment to enhancing vehicle performance, emphasizing the need for manufacturers and consumers alike to prioritize bearing selection and care in the pursuit of optimal safety and efficiency on the road.

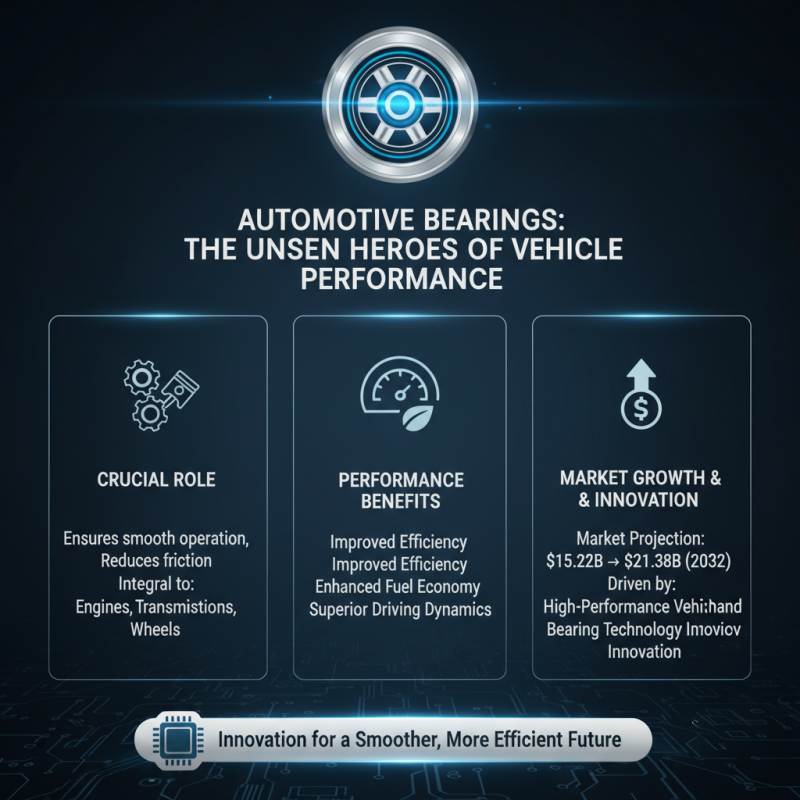

The Role of Automotive Bearings in Enhancing Vehicle Performance

Automotive bearings play a crucial role in enhancing vehicle performance by ensuring smooth operation and reducing friction between moving parts. Their importance cannot be overstated, as they are integral to various systems within a vehicle, including engines, transmissions, and wheel assemblies. High-quality bearings can improve efficiency, contribute to fuel economy, and enhance overall driving dynamics. As the global automotive bearing market is projected to grow from $15.22 billion in 2024 to $21.38 billion by 2032, the focus on innovation in bearing technology is evident, aligning with the increasing demand for high-performance vehicles.

In electric vehicles, for instance, bearings are essential in the power transmission systems of electric drivetrains. They help in controlling motor speed and torque, which are vital for meeting the drivers' power demands. Recent advancements, like those seen in specialized bearings designed for electric drive applications, demonstrate how the industry is evolving to meet the challenges posed by modern automotive technologies. This shift underscores the vital link between bearing performance and improved vehicle safety and efficiency.

Types of Automotive Bearings and Their Specific Functions in Vehicles

Automotive bearings play a crucial role in enhancing vehicle performance and ensuring safety. These components are classified into various types, each serving specific functions that contribute to the smooth operation of different vehicle systems. For instance, wheel bearings facilitate the rotation of the wheels while reducing friction, enhancing overall handling and ride comfort. Engine bearings support the moving parts within the engine, ensuring minimal wear and efficient power transfer. In addition, transmission bearings are essential for facilitating smooth gear shifts and maintaining transmission efficiency.

The demand for automotive bearings is witnessing substantial growth, driven by factors such as the rising popularity of electric vehicles (EVs), improvements in lightweight materials, and increasing fuel efficiency concerns. The global automotive bearing market is projected to generate significant revenue by 2031, indicative of a growing reliance on these components for optimal vehicle function. As the industry advances, innovations in bearing technology will further support vehicle performance and safety, making these components integral to the evolution of modern automotive engineering.

Impact of Bearing Quality on Vehicle Safety Standards and Reliability

The quality of automotive bearings plays a pivotal role in ensuring vehicle safety standards and overall reliability. High-quality bearings reduce friction and wear, which are critical factors in maintaining optimal performance under various driving conditions. When bearings are made with superior materials and precision engineering, they can better handle the stresses and strains experienced during operation. This not only enhances the lifespan of the bearings themselves but also contributes to more stable handling and braking, which are essential for safe vehicle operation.

Moreover, low-quality bearings can lead to catastrophic failures that compromise safety. Poorly manufactured bearings may fail prematurely, resulting in unexpected breakdowns and potential accidents. Such failures can directly impact critical components like the wheels and suspension systems, increasing the risk of loss of vehicle control. Therefore, investing in high-quality bearings is not merely a matter of performance; it is essential for adhering to safety regulations and ensuring the reliability of vehicles on the road. By prioritizing bearing quality, manufacturers can significantly improve the safety profiles of their vehicles, ultimately protecting both drivers and passengers.

Why Automotive Bearings Are Essential for Vehicle Performance and Safety - Impact of Bearing Quality on Vehicle Safety Standards and Reliability

| Bearing Type |

Material |

Load Capacity (N) |

Durability (hrs) |

Impact on Safety |

Reliability Rating (1-10) |

| Ball Bearing |

Steel |

5000 |

1500 |

High |

9 |

| Roller Bearing |

Chrome Steel |

8000 |

2000 |

Very High |

10 |

| Sleeve Bearing |

Bronze |

3000 |

1000 |

Medium |

7 |

| Thrust Bearing |

Stainless Steel |

6000 |

1800 |

High |

8 |

| Magnetic Bearing |

Composite Materials |

9000 |

2500 |

Very High |

10 |

Industry Statistics: Bearing Failures and Their Consequences for Drivers

Bearing failures in automotive vehicles can have dire consequences, directly impacting both performance and safety. According to industry statistics, a significant percentage of vehicle breakdowns and accidents can be attributed to malfunctioning bearings. These components are critical as they allow for smooth rotation of wheels, hubs, and other key parts of the vehicle. When bearings fail, it can lead to wheel lock-up, erratic steering, and even total loss of control in extreme cases.

Moreover, the financial implications of bearing failures extend beyond immediate repairs. The cost of replacing damaged parts, potential lawsuits from accidents, and increased insurance premiums can take a substantial toll on drivers. In some instances, these failures can lead to catastrophic incidents, underscoring the importance of regular maintenance and monitoring of bearing conditions. Awareness of the potential risks associated with bearing failures is essential for drivers; they must understand that proactive measures can contribute significantly to vehicle longevity and overall road safety.

Future Trends: Innovations in Automotive Bearings and Performance Improvements

The future of automotive bearings is poised for significant innovations as the industry embraces the shift towards electric and smart vehicles. Emerging technologies are driving the development of new bearing materials and designs that enhance performance and efficiency. This transformation is not only about optimizing the traditional functions of bearings but also about integrating advanced features such as better load distribution, reduced friction, and improved durability, which are critical for electric drivetrains.

As the automotive bearings market is expected to grow significantly—from a valuation of $3.05 billion in 2023 to an estimated $4.06 billion by 2024—manufacturers are focusing on research and development to meet the evolving demands of the automotive industry. Innovations in manufacturing processes, such as additive manufacturing and precision engineering, are enabling the creation of lightweight and more resilient bearings. These advancements will play a crucial role in enhancing vehicle performance and safety, ultimately contributing to a more sustainable and efficient automotive ecosystem.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us