Bearing Design Tips for Choosing the Right Bearings?

Effective bearing design is crucial for various mechanical systems. Selecting the right bearings can significantly impact performance and longevity. When considering different applications, factors like load, speed, and environment must be analyzed.

Many engineers overlook the importance of precision in bearing design. A wrong choice can lead to premature failure or inefficiency. Often, there is a lack of understanding about the various types of bearings available. Each type comes with its strengths and weaknesses.

Moreover, design considerations extend beyond just the bearing type itself. It is essential to think about mounting, lubrication, and alignment. Engineers may sometimes be too focused on complexity. Simplicity can be effective in bearing design, leading to better solutions. By reevaluating choices and acknowledging potential errors, a smoother design process can ensue.

Understanding Different Types of Bearings and Their Applications

Choosing the right bearings can be challenging. Various types serve different purposes. Understanding these differences is essential for effective applications.

Ball bearings are commonly used in machinery. They handle higher speeds and lighter loads. In contrast, roller bearings are ideal for heavy loads. They provide more contact area, leading to better weight distribution. It’s crucial to consider your specific needs when selecting between them.

Tips: Always assess the load requirements before making a choice. Not all bearings are equal in performance. Additionally, lubrication is key for longevity. Regular maintenance checks can prevent failures. Sometimes, ignoring these details can lead to costly repairs. The wrong bearing choice can disrupt operations. Reflect on past decisions to improve future selections.

Key Factors to Consider When Selecting Bearings

When selecting bearings, several key factors come into play. First, consider the load requirements. Bearings must support the weight of the machinery they operate within. A mismatch can lead to premature wear. The environment also matters. Dust, moisture, and extreme temperatures can compromise performance. It's important to choose materials that withstand these conditions.

Another factor is the speed at which bearings will operate. High-speed applications require specific designs to reduce friction. Noise levels are also relevant. Some applications demand quieter operations, requiring careful selection of bearing types.

There might be instances where the chosen bearing fails to meet expectations. This can happen when assumptions about load, speed, and environment are incorrect. Early analysis can prevent costly errors. Taking time to review all factors can lead to better performance and longevity of equipment.

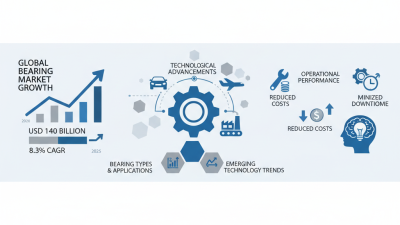

Bearing Design Tips for Choosing the Right Bearings

This chart represents the importance rating of key factors to consider when selecting bearings. Each factor has been rated on a scale from 1 to 10, where 10 indicates the highest importance.

Evaluating Load Ratings for Optimal Bearing Performance

When evaluating load ratings for optimal bearing performance, it’s crucial to consider the working environment and application. Bearings withstand various forces, and proper load ratings help ensure durability. According to a recent industry report, approximately 70% of bearing failures stem from inappropriate load selection. Incorrect ratings lead to early wear and performance issues.

Tip: Always refer to load rating charts. Use static and dynamic load ratings to assess the appropriate bearing type for your application. Misjudging these can lead to costly repairs. Monitoring operating conditions is equally important.

Additionally, keep in mind that environmental factors play a significant role. Temperature fluctuations and contamination can affect load capacity. A study highlighted that bearings operating above recommended temperatures show a marked increase in failure rates.

Tip: Regular maintenance checks can be invaluable. They can help identify signs of wear before they turn critical. Evaluating bearing performance under real-world conditions gives better insight into their longevity. Ultimately, your approach to load ratings will directly influence performance and reliability.

Material Selection for Bearings: A Comprehensive Guide

Choosing the right material for bearings is crucial for ensuring performance and longevity. Different applications require different materials. For example, steel bearings are commonly used due to their high load capacity and durability. According to a 2022 report by the International Bearing Industry Research Association, over 60% of bearings produced are made from steel alloys. However, they may not perform well in corrosive environments.

Alternatives, such as ceramic bearings, offer low friction and high corrosion resistance. While they can withstand higher temperatures, they are often more brittle than steel. The same report indicates that the market for ceramic bearings is increasing, projected to grow by 15% annually. These materials reduce maintenance costs significantly but can be costly upfront.

Material selection must consider the operating environment. Factors like temperature, moisture, and chemical exposure influence durability. For instance, stainless steel bearings might be better in wet conditions despite their higher cost. Failing to choose the right material can lead to premature bearing failure, causing unexpected downtime. Rethinking material options based on specific needs is essential for optimal performance.

Maintenance Tips to Enhance Bearing Longevity and Efficiency

Proper maintenance is crucial for extending the life of your bearings. Regular inspection can identify wear or abnormal sounds. Check for signs of overheating or corrosion. These issues can lead to premature failure. Keep a close eye on vibration levels as well. High vibrations signal misalignment or imbalance. Address these problems quickly to avoid further damage.

Lubrication plays a significant role in bearing efficiency. Choose the right lubricant based on your environment. Grease or oil can differ in performance levels. Overlubrication can cause heat build-up, while underlubrication leads to friction. Use the manufacturer’s recommendations as a guideline but adjust based on usage. Regularly clean grease fittings and ensure seals are intact. This prevents contaminants from entering the bearing.

Proper storage is often overlooked. Store bearings in a clean, dry environment. Humidity can lead to rust and degradation. When not in use, cover them to protect from dust and dirt. Even small particles can cause significant damage later. Reflecting on these practices helps maintain optimal performance and avoid costly failures.

Bearing Design Tips for Choosing the Right Bearings

| Bearing Type |

Material |

Load Capacity (kg) |

Speed Rating (RPM) |

Cost ($) |

Maintenance Interval (Months) |

| Ball Bearing |

Steel |

500 |

3000 |

25 |

12 |

| Roller Bearing |

Chromium Steel |

800 |

2000 |

30 |

6 |

| Thrust Bearing |

Bronze |

300 |

1500 |

40 |

18 |

| Spherical Bearing |

Stainless Steel |

700 |

4000 |

50 |

24 |

| Fluid Bearing |

Polymer |

200 |

1000 |

15 |

36 |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us