Top Bearing Design Trends to Watch in 2025 for Optimal Performance

As the manufacturing landscape evolves, the importance of innovative bearing design is becoming increasingly pivotal to achieve optimal performance in various applications. According to a report by MarketsandMarkets, the global bearing market is projected to reach $214.4 billion by 2025, growing at a CAGR of 6.5%. This growth underscores the need for engineers and designers to stay abreast of emerging trends that will influence bearing design practices.

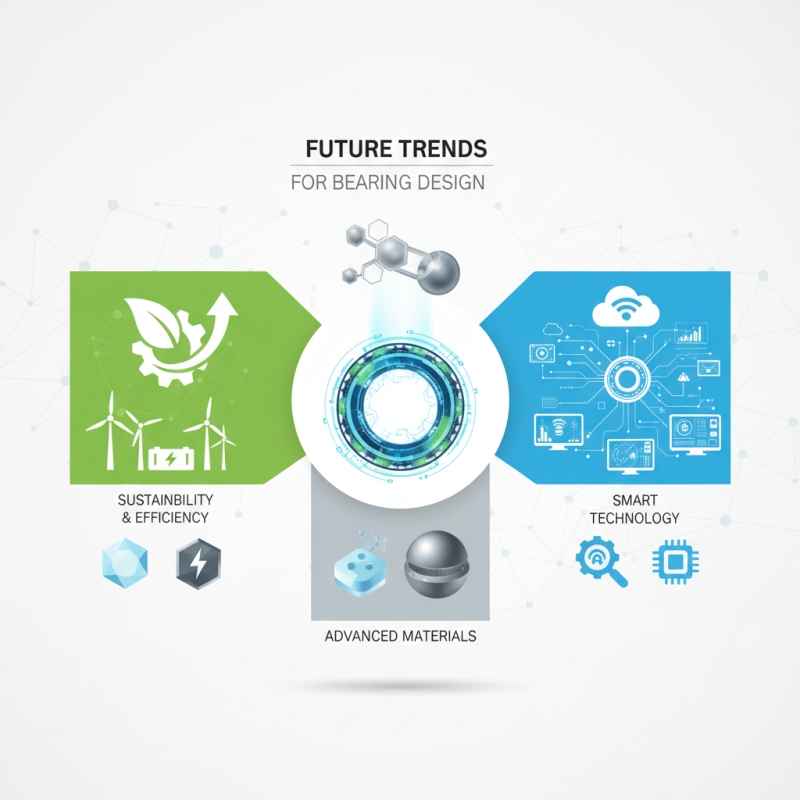

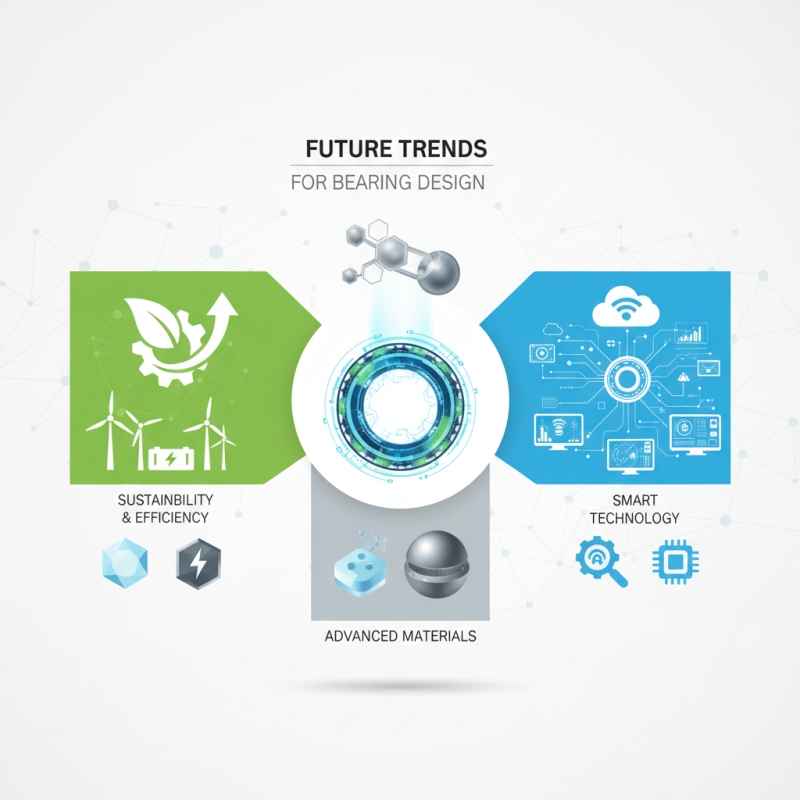

In 2025, we expect to see a heightened focus on sustainability and efficiency within bearing design, driven by regulatory demands and market preferences for eco-friendly solutions. Advanced materials, such as polymer composites and advanced steel alloys, will play a crucial role in enhancing the durability and performance of bearings while reducing environmental impact. Furthermore, the integration of smart technology, including IoT capabilities for predictive maintenance, will redefine how bearings are designed and utilized in machinery and vehicles.

As industries strive for more reliable and efficient systems, understanding these bearing design trends is essential for engineers aiming to enhance product lifespan and operational efficiency. Keeping pace with these advancements not only promotes innovation but also positions companies to meet the growing demands of a competitive marketplace.

Emerging Materials and Their Impact on Bearing Performance

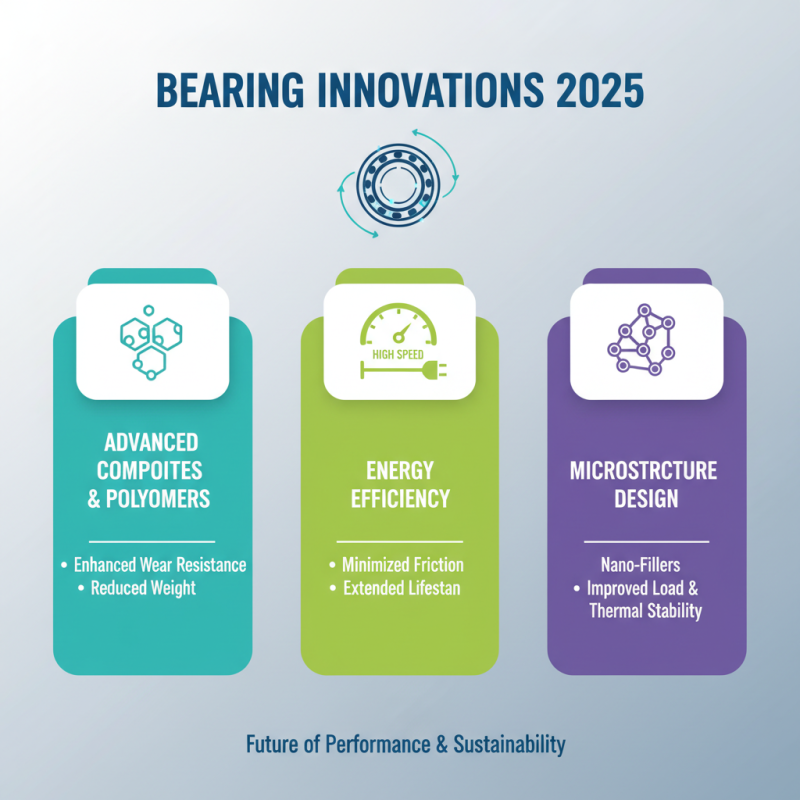

Emerging materials play a crucial role in the ongoing evolution of bearing designs, significantly impacting performance across various applications. In 2025, we are likely to see an increasing adoption of advanced composites and polymer-based materials that enhance wear resistance while reducing weight. These materials not only improve the operational lifespan of bearings but also contribute to energy efficiency by minimizing friction in high-speed applications. Innovations in microstructure design, such as the incorporation of nano-fillers, can further enhance load-bearing capabilities and thermal stability, leading to a noteworthy performance boost.

Moreover, the integration of smart materials that respond to environmental changes is anticipated to revolutionize bearing functionality. These materials can adapt to varying loads and temperatures, providing real-time feedback to enhance performance and reliability. This adaptability can lead to predictive maintenance practices, reducing downtime and maintenance costs significantly. As engineers and designers explore these novel materials, the focus will be on achieving optimal performance while addressing environmental sustainability concerns, ensuring that the future of bearing design remains both innovative and responsible.

Innovative Manufacturing Techniques for Enhanced Bearing Durability

In 2025, the bearing industry is set to witness a profound transformation driven by innovative manufacturing techniques aimed at enhancing bearing durability. As the demand for high-performance bearings continues to grow across various sectors, integrative processes like additive manufacturing and advanced surface treatments are gaining prominence. These methods not only improve the lifespan of bearings but also allow for the production of complex geometries that were previously unattainable.

One of the key techniques on the rise is the use of 3D printing technologies, which enable the customization of bearing designs. This flexibility leads to optimizing weight and performance, which is especially critical in industries such as aerospace and automotive. Another innovation involves advanced coating technologies that enhance resistance to wear and corrosion, thereby significantly increasing the operational reliability of bearings under extreme conditions.

Tips for ensuring enhanced bearing durability include regularly assessing the operating environment and selecting materials that are best suited for specific applications. It is also advisable to invest in predictive maintenance technologies that can detect potential failures before they occur. Moreover, staying updated with the latest manufacturing advancements can provide essential insights into refining your bearing selection and maintenance protocols, ultimately leading to optimal performance in the long run.

Top Bearing Design Trends to Watch in 2025 for Optimal Performance

This chart illustrates the projected advancements in bearing design trends based on innovative manufacturing techniques that enhance durability, performance, and overall efficiency.

Smart Bearings: Integrating IoT for Real-Time Monitoring and Analytics

The integration of Internet of Things (IoT) technology into bearing design is set to revolutionize the way industries monitor and analyze performance. Smart bearings, equipped with sensors, consistently gather and transmit data regarding their operational conditions, including temperature, vibration, and load. This real-time monitoring allows for immediate insights into bearing health, reducing the likelihood of unexpected failures. By leveraging advanced analytics, operators can identify inefficiencies and implement proactive maintenance strategies, ultimately enhancing the longevity and reliability of machinery.

Moreover, the use of IoT in bearings is not confined to simply data collection. Advanced algorithms can analyze trends over time, enabling predictive maintenance and minimizing downtime. This shift from reactive to proactive management transforms maintenance schedules from routine checks to condition-based interventions. As industries continue to embrace smart manufacturing principles, the role of smart bearings in ensuring optimal performance and efficiency becomes increasingly critical. By harnessing real-time data analytics, companies can optimize their operations, leading to improved productivity and cost savings.

Sustainability in Bearing Design: Greener Options for the Future

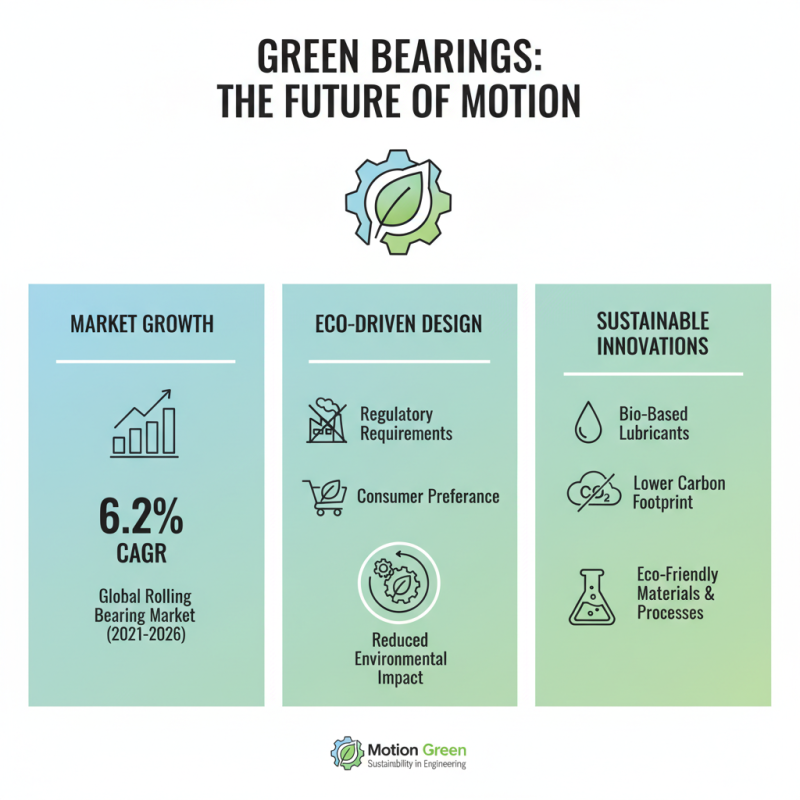

Sustainability is becoming a crucial focus in bearing design, driven by both regulatory requirements and a growing consumer preference for environmentally friendly products. According to a report from Research and Markets, the global rolling bearing market is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026, with a significant emphasis on sustainable practices. As manufacturers aim to meet this demand, many are exploring materials and processes that reduce environmental impact. For instance, the incorporation of bio-based synthetic lubricants can significantly lower carbon footprints while maintaining optimal performance across various applications.

Additionally, initiatives to enhance the lifecycle of bearings through advanced design and superior materials are gaining traction. It is reported that bearings designed for longer service life can reduce waste and the need for frequent replacements. By leveraging materials such as recycled metals and advanced polymers, manufacturers can not only improve the sustainability of their products but also enhance their efficiency. As the industry continues to adopt practices aligned with circular economy principles, we can expect innovative designs that not only perform effectively but also contribute positively to environmental goals. Emerging trends indicate a shift towards modular bearing designs, allowing for easy upgrades and repairs, which further supports sustainability in the sector.

Customization and Modularity: Trends in Tailored Bearing Solutions

The bearing industry is experiencing a significant shift towards customization and modularity, responding to the diverse needs of modern applications. As industries strive for enhanced performance and efficiency, tailored bearing solutions are becoming essential. Customization allows manufacturers to design bearings that meet specific operational requirements, which can lead to improved longevity and performance under unique conditions. This trend is particularly advantageous for sectors such as automation, aerospace, and renewable energy, where standard solutions may fall short.

Tips for implementing customized bearing designs include conducting a thorough analysis of the application requirements, including load conditions and environmental factors. Collaborating closely with engineering teams can help identify key performance issues and design challenges early in the process. Additionally, consider leveraging modular designs that allow for easy adjustments and upgrades, enhancing the lifespan and adaptability of the bearing systems.

Modularity in bearing designs not only simplifies maintenance but also offers flexibility for future modifications. This trend enables manufacturers to easily swap out components to adapt to new technologies or enhance performance without requiring a complete redesign. As the demand for efficient and adaptable bearing solutions increases, companies that embrace customization and modularity will be well-positioned to meet the evolving needs of their clients in 2025 and beyond.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us