What is a Bearing Lock and How Does It Enhance Machinery Performance

In the realm of industrial machinery and equipment, the significance of effective components cannot be overstated. One such crucial element is the Bearing Lock, an innovative solution that plays a pivotal role in enhancing the performance and longevity of machinery. Bearing Locks not only secure bearings in place but also minimize the risk of slippage and vibration, which can lead to operational inefficiencies and equipment failure. By understanding the mechanics of Bearing Locks and their applications, engineers and technicians can make informed decisions that optimize machine functionality. This exploration of Bearing Locks will delve into their design, benefits, and potential to revolutionize the reliability of various mechanical systems, ultimately demonstrating why they are considered essential in the pursuit of peak performance and maintenance efficiency in industrial settings.

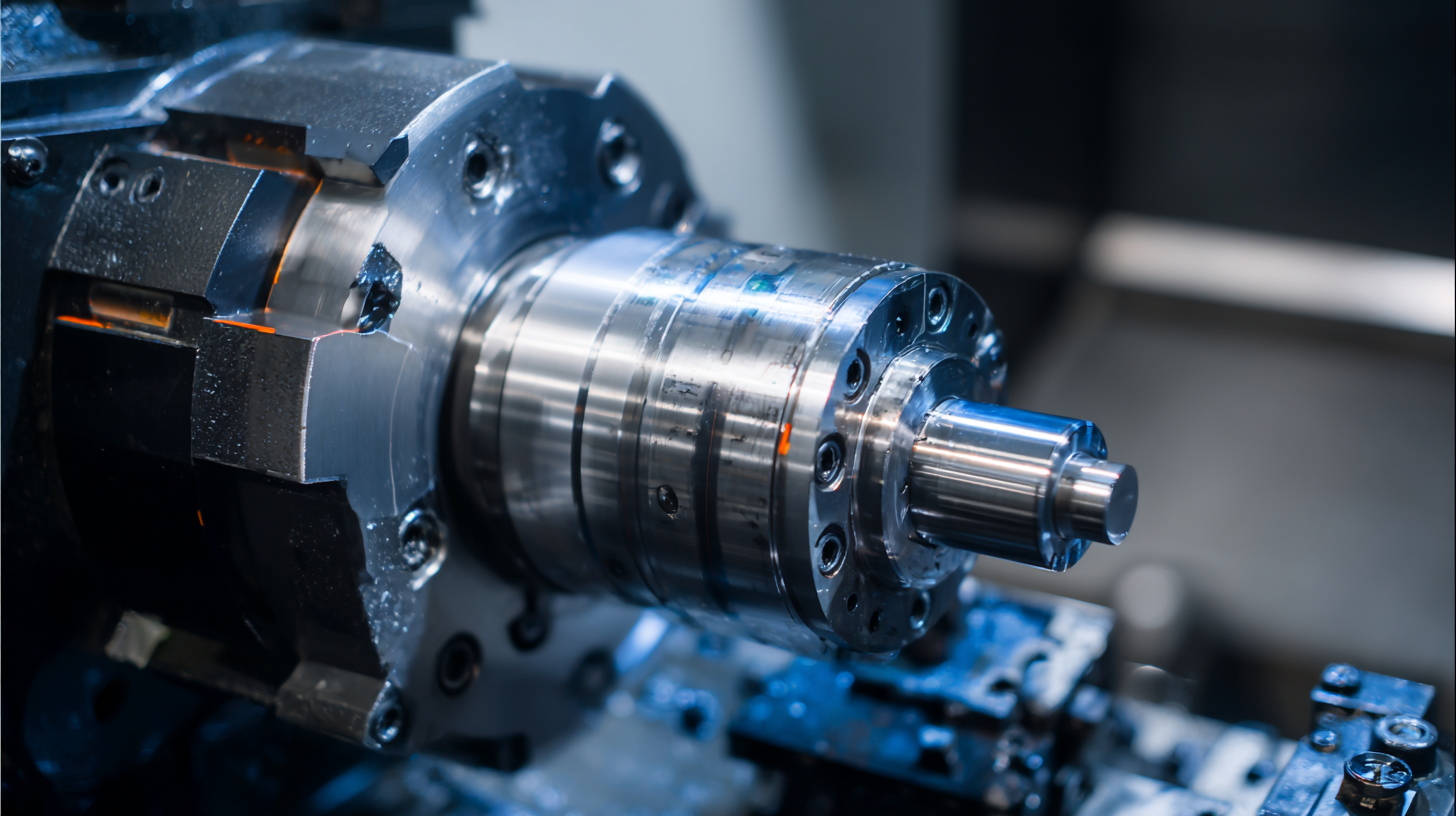

Understanding the Concept of Bearing Locks in Machinery Applications

Bearing locks are crucial components in the machinery sector, enhancing performance and reliability. Understanding bearing locks involves recognizing how these devices secure bearings in place, preventing misalignment and ensuring smooth operation. By firmly holding the bearings, they reduce wear and tear on machinery, which can lead to costly downtimes and repairs. This stability is especially vital in high-speed applications where vibrations and forces can easily displace components.

Tips for Implementing Bearing Locks:

- Always choose the appropriate type of bearing lock for your specific machinery needs, as compatibility plays a significant role in performance.

- Regular maintenance and inspection of bearing locks can prevent unexpected failures and extends the life of your machinery. Ensuring that all components are properly aligned and secured will enhance overall efficiency.

In addition to operational advantages, implementing bearing locks can also contribute to

workplace safety by minimizing the risk of machinery malfunction. Thus, incorporating these locks into your equipment can provide a sound strategy for boosting both performance and safety in any industrial setting.

Key Functions of Bearing Locks in Enhancing Equipment Efficiency

Bearing locks play a crucial role in enhancing the efficiency of machinery by ensuring that rolling element bearings remain secure and stable during operation. They prevent axial movement and rotation of bearing components, which can lead to premature wear and reduced performance. According to recent studies, implementing effective bearing lock designs has shown to improve reliability in complex machinery by as much as 30%, thereby extending operational lifespan and reducing maintenance costs.

In industries such as wind power and automotive manufacturing, the benefits of bearing locks are evident. As turbine rotor sizes increase, the stress on main bearings escalates, necessitating reliable locking mechanisms to prevent failure. Research indicates that advancements in bearing technology can significantly improve mechanical efficiency, with some traction motors achieving up to 90% efficiency when paired with optimized bearing locks. These enhancements contribute not only to the longevity of equipment but also to overall energy savings and performance metrics in manufacturing and energy sectors.

Industry Statistics: Impact of Bearing Locks on Maintenance Intervals

Bearing locks play a pivotal role in optimizing machinery performance by ensuring stability and precision in rotating components. By securing bearings in place, these locks prevent axial and radial movement, which can lead to excessive wear and potential mechanical failure. The recent upgrades in bearing block units and housings reflect an industry commitment to enhancing machinery reliability and extending maintenance intervals.

Industry statistics indicate that the implementation of bearing locks can significantly reduce maintenance frequency. For example, in high-demand environments like the Panama Canal, where lock gates and valves require consistent operation, the use of advanced bearing solutions has proven essential. The deployment of thousands of rolling bearings in critical systems enhances operational efficiency and minimizes downtime. This underscores the value of investing in quality bearing solutions, as they not only improve machinery performance but also lead to considerable cost savings in maintenance and repairs.

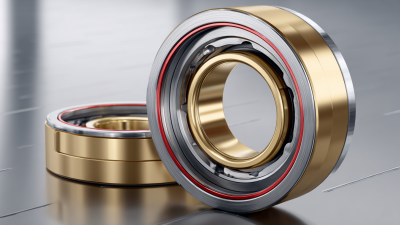

Comparison of Bearing Lock Designs and Their Performance Metrics

Bearing locks are essential components in machinery that secure bearings in place, preventing them from moving or spinning unintentionally. Various designs of bearing locks, such as set screw locks, snap ring locks, and taper-locks, cater to different operational requirements and environments. Each design features unique mechanisms for securing bearings, impacting their overall performance. For instance, set screw locks are simplicity in design, providing adequate holding power for moderate loads. However, they may not perform well under high rotational speeds, potentially leading to slippage.

In contrast, taper-locks are engineered to distribute load evenly along the bearing shaft, enhancing stability and reducing the likelihood of wear or failure. Snap ring locks offer ease of installation and removal, making them favorable for applications requiring frequent maintenance. Performance metrics, such as load capacity, ease of disassembly, and resistance to misalignment, should be considered when selecting a bearing lock design. Understanding these differences allows engineers to make informed decisions that ultimately enhance machinery efficiency and longevity.

What is a Bearing Lock and How Does It Enhance Machinery Performance - Comparison of Bearing Lock Designs and Their Performance Metrics

| Bearing Lock Design |

Material |

Load Capacity (N) |

Temperature Range (°C) |

Lifetime (Hours) |

Cost ($) |

| Type A |

Steel |

5000 |

-20 to 120 |

3000 |

150 |

| Type B |

Aluminum Alloy |

3500 |

-10 to 100 |

2500 |

120 |

| Type C |

Composite |

4300 |

-30 to 150 |

2800 |

180 |

| Type D |

Bronze |

6000 |

-40 to 200 |

3500 |

200 |

Best Practices for Implementing Bearing Locks in Industrial Systems

Bearing locks are crucial components in enhancing machinery performance, especially in industrial systems where reliability and efficiency are paramount. Implementing best practices for bearing locks can substantially reduce maintenance costs and downtime. According to a report by the International Journal of Engineering Research, utilizing advanced locking mechanisms can extend the lifespan of bearings by up to 20%, resulting in increased productivity and lower operational expenses.

When integrating bearing locks into industrial systems, it is essential to follow specific guidelines to ensure optimal performance. For instance, ensuring proper alignment during installation can minimize wear and tear, as misalignment often leads to premature failure. Data from Machinery Lubrication magazine indicates that 30% of bearing failures can be attributed to improper installation. Moreover, regular inspections and adjustments of the bearing locks can help identify potential issues before they escalate into costly repairs, reinforcing the concept that proactive maintenance strategies yield significant returns on investment in industrial operations.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us