What is Bearing Lock and How Does it Work in 2026?

In the fast-evolving world of machinery, understanding "Bearing Lock" has become crucial. In 2026, bearing locks are more sophisticated yet sometimes misunderstood. As John Thompson, a leading expert in the bearing industry, stated, "Bearing locks are the silent saviors of machinery efficiency." This statement highlights the importance of recognizing how these components enhance performance.

Bearing locks prevent unwanted movement and ensure stability. They are essential in various applications, from automotive engines to industrial machines. Despite their effectiveness, some users overlook their maintenance. Such negligence can lead to machinery failure. Regularly checking locking mechanisms is vital.

As technology advances, challenges emerge. Some designs may not fit all machines perfectly. Engineers must ensure compatibility when choosing a bearing lock. The journey of mastering these components is ongoing. Recognizing their limitations will lead to better solutions in the future. It's essential to embrace this challenge. Understanding "Bearing Lock" is not just about mechanics—it's about future-proofing equipment.

What is Bearing Lock and Its Importance in Mechanical Applications

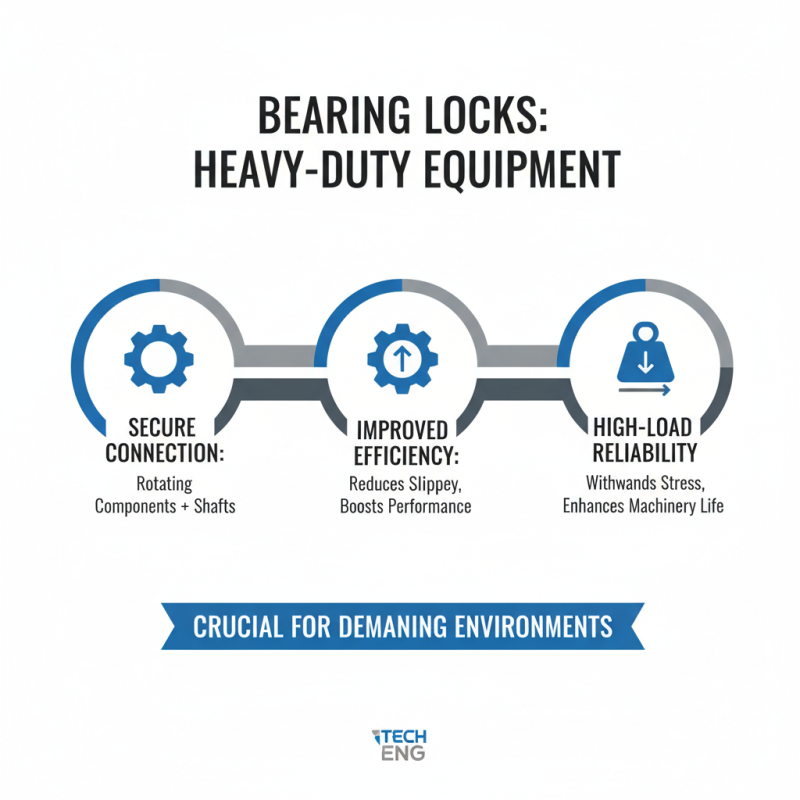

Bearing locks play a crucial role in mechanical applications. They secure bearings onto shafts, preventing them from slipping or rotating unexpectedly. This is particularly important in high-speed machinery where precision and stability are essential. Bearing locks help maintain alignment, reduce vibration, and extend the lifespan of components.

In 2026, advancements in materials and design have improved the effectiveness of bearing locks. Many engineers now prefer innovative locking mechanisms. These modern solutions often provide better reliability and ease of installation. However, some older methods still present challenges. They can fail under stress or be difficult to maintain. Frequent inspections and updates may be required to ensure optimal performance.

Mechanical systems rely heavily on effective locking methods. Bearing locks contribute significantly to the reliability of machinery. Poorly designed locks can lead to failures, resulting in costly downtimes. It's vital for engineers to continuously evaluate their locking mechanisms. This reflection can lead to innovations that enhance performance and safety in various applications.

Understanding Bearing Lock and Its Importance in Mechanical Applications (2026)

The Mechanics of Bearing Lock: How It Functions in Modern Machinery

Bearing lock is crucial in modern machinery. It ensures that moving parts stay securely in place. The mechanism operates using a simple yet effective design. When engaged, it tightens around the shaft, preventing unwanted movement. This is vital for equipment stability.

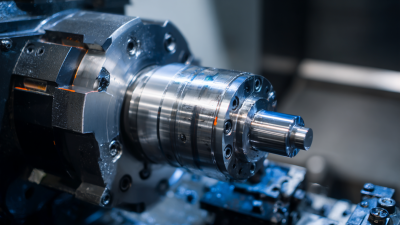

In 2026, advanced materials enhance bearing locks. Incorporating lightweight and durable components boosts performance. Manufacturers focus on reducing friction, which prolongs life. However, the complexity can lead to oversights. Improper installation may cause failures, disrupting operations.

Maintenance remains essential. Regular checks of the bearing lock are necessary. Observing wear or damage early can prevent significant issues. Users often overlook this routine, risking costly repairs. Understanding the mechanics is key to effective use. Mistakes can happen, and learning from them is important.

What is Bearing Lock and How Does it Work in 2026?

| Component |

Function |

Materials Used |

Application Fields |

Advantages |

| Bearing Sleeve |

Locks the bearing in place to prevent movement |

Steel, Aluminum |

Automotive, Industrial Machinery |

Reduces vibrations, enhances stability |

| Locknut |

Secures the bearing and maintains axial pressure |

Carbon Steel, Stainless Steel |

Aerospace, Marine |

Easy installation and removal, reliable performance |

| Cage |

Guides and separates the rolling elements within the bearing |

Polyamide, Brass |

Electrical, Robotics |

Reduces friction, minimizes wear and tear |

| Seals |

Prevent contamination and loss of lubricant |

Nitrile, Viton |

Mining, Agriculture |

Extends lifespan of bearings, enhances reliability |

Types of Bearing Locks Used in Industry Today

Bearing locks are essential components in various industrial applications, ensuring that rotating equipment operates smoothly. In today's industry, several types of bearing locks are commonly used. Two of the most prominent types are locknuts and setscrews. Locknuts provide a secure method for fastening bearings onto shafts by creating a tight grip.

Setscrews, on the other hand, are inserted into a threaded hole on the bearing. They create friction to hold the bearing in position.

According to a report from the Engineering Industry Association, up to 40% of mechanical failures can be linked to improper bearing installation due to insufficient locking methods. This underscores the necessity for reliable bearing locks. The average lifespan of a properly locked bearing can increase by 25%, showing the importance of using the right locking mechanism.

Tips: Ensure compatibility between the bearing and lock type. Always double-check torque specifications for tightness. Neglecting these details can lead to premature bearing failure. Consider regular inspections to prevent issues early. A simple oversight can result in costly downtime.

Future Trends in Bearing Lock Technology and Its Applications

Bearing lock technology continues to evolve rapidly in 2026. This advancement opens new avenues for industries reliant on precision machinery. Innovations focus on improving durability and efficiency. Smart bearings are a notable trend. They provide real-time monitoring and data analytics. These features enhance safety and reduce downtime.

Tips: Regular maintenance is key to prolonging bearing life. Check for unusual noises or vibrations. These can indicate issues that need attention.

Another trend involves sustainability. Using eco-friendly materials in bearing locks is becoming essential. Manufacturers are exploring recyclable components. The push for greener solutions aligns with global environmental goals. However, challenges remain. The transition may lead to performance trade-offs. Rethinking traditional designs is crucial.

Tips: Always consider the environment when choosing materials. Sustainable options may sometimes come with unexpected drawbacks. Evaluate all aspects before making a decision.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us