Top Benefits of Steel Bearings for Industrial Applications?

In the realm of industrial applications, steel bearings play a crucial role. These components are essential for machinery, offering durability and reliability. Steel bearings hold up under heavy loads. They also resist wear and corrosion. The strength of these materials allows machines to operate more efficiently.

Many industries rely on steel bearings for seamless movement. From automotive to aerospace, their impact is significant. The precision they offer leads to improved performance. However, not all steel bearings are created equal. Choosing the right one requires careful consideration. Each application has unique demands.

It's vital to understand both the advantages and limitations of steel bearings. While they excel in many areas, flaws can hinder performance. Regular maintenance and appropriate selection are critical for longevity. This reflection on steel bearings reveals their true potential when used correctly.

Benefits of Steel Bearings: Longevity and Durability in Industrial Use

Steel bearings are indispensable in various industrial applications. Their longevity and durability set them apart from other materials. Manufacturers often report that steel bearings can operate efficiently for over 20,000 hours under optimal conditions. This impressive lifespan drastically reduces the need for frequent replacements.

In high-load scenarios, steel bearings show remarkable performance. Research indicates that they can withstand extreme pressures, which is crucial in industries like automation and transportation. Moreover, the resistance of steel bearings to wear and fatigue contributes to fewer operational disruptions. The increased uptime translates into higher productivity.

However, not all steel bearings perform equally. Some may require additional lubrication or suffer from corrosion in specific environments. This highlights the importance of selecting the right type for critical applications. While steel bearings generally offer excellent longevity, the nuances in performance warrant careful consideration and regular maintenance to achieve the best results.

Enhanced Load Capacity: Understanding Steel Bearings' Performance Metrics

Steel bearings play a critical role in industrial applications, particularly due to their enhanced load capacity. Studies indicate that steel bearings can support loads exceeding 100,000 pounds, depending on size and type. This performance metric makes them suitable for heavy-duty machinery. For instance, in manufacturing, steel bearings maintain efficiency under substantial pressure, preventing premature failure.

The fatigue life of steel bearings is another notable advantage. When subjected to dynamic loads, these bearings often last up to 20% longer than their counterparts made from other materials. This durability reduces downtime and maintenance costs, which can be as high as $1 million annually for large facilities. However, improper installation can negate these benefits. A misplaced bearing can cause uneven wear or catastrophic failure. Regular inspections are essential to ensure optimal performance.

Moreover, while steel bearings excel under high loads, they are sensitive to environmental factors. Moisture and corrosion can limit lifespan. Some reports suggest that bearing failure due to corrosion accounts for nearly 30% of all industrial equipment failures. It’s crucial to weigh these risks against the excellent attributes of steel bearings. Ultimately, understanding these metrics can enhance decision-making in equipment design and maintenance strategies.

Top Benefits of Steel Bearings for Industrial Applications

| Benefit |

Description |

Performance Metric |

Application Example |

| Enhanced Load Capacity |

Steel bearings can handle higher loads compared to plastic or ceramic counterparts, improving overall performance. |

Up to 30% higher load capacity than traditional bearings |

Heavy machinery, such as cranes and industrial presses |

| Durability |

Steel is resistant to wear and degradation, leading to longer operational life. |

5-10 years of operational life under standard conditions |

Automotive applications and manufacturing equipment |

| Lower Maintenance Costs |

Fewer failures and longer service intervals reduce overall maintenance expenditure. |

Maintenance costs reduced by up to 25% |

Conveyor systems in warehouses |

| Temperature Resistance |

Steel bearings can operate effectively in a wider temperature range. |

-40°C to 120°C without performance degradation |

High-temperature machining and industrial ovens |

| Precision |

Manufactured for high accuracy, benefitting applications requiring precision components. |

Tolerances within ±0.01 mm |

Robotics and aerospace components |

Resistance to Extreme Conditions: Corrosion and Temperature Tolerance

Steel bearings are essential for many industrial applications, especially in extreme environments. They excel in resisting corrosion, which is crucial for machinery operating in humid or chemically aggressive settings. Industries like manufacturing and oil production often face moisture and harmful substances. Steel bearings withstand these challenges, ensuring longevity and reliability.

Temperature tolerance is another significant advantage of steel bearings. They can operate in both high and low temperature extremes. This capability prevents failures that can lead to costly downtime. However, not all steel bearings tolerate heat equally. Some may warp or lose performance under excessive heat. It’s vital for users to assess working conditions carefully.

In real-world applications, selecting the right bearing is crucial. Even minor errors in specification can result in issues. Users should consider various factors, such as load, speed, and environment, when choosing. Understanding specific needs can lead to better performance and less maintenance. Despite their advantages, steel bearings require some reflection before use. Each application can vary, so it’s essential to evaluate and adapt accordingly.

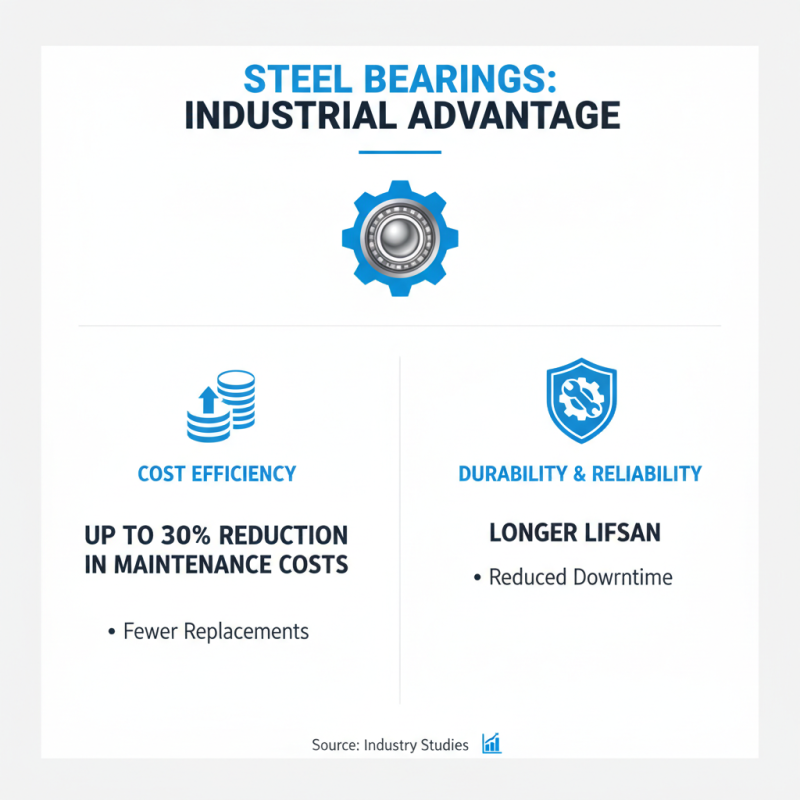

Cost Efficiency: Long-Term Savings with Steel Bearing Applications

Steel bearings have gained popularity in industrial applications for their cost efficiency and long-term savings. Studies show that using steel bearings can reduce maintenance costs by up to 30%. This is primarily due to their durability and reliability. For instance, steel bearings often last longer than their alternatives, leading to fewer replacements and lower overall expenditures.

Additionally, the initial investment in steel bearings can be outweighed by their performance. A report from an industry association noted that steel bearings could improve energy efficiency by 15%. This reduction in energy consumption directly impacts operational costs. However, some industries might hesitate, fearing higher upfront costs. Yet, when examining the lifespan and performance, the logic shifts. In the long run, the enhanced reliability means less downtime and higher productivity.

Despite these advantages, a few companies struggle with integration. Transitioning to steel bearings requires careful assessment of compatibility with existing systems. Every machinery has unique requirements. It’s essential to evaluate whether the long-term benefits justify the initial complexity. Failing to do so could result in unexpected challenges. Thus, a thorough evaluation of both short-term investments and long-term returns remains crucial for smart decision-making.

Reduction in Maintenance Downtime: Impacts on Industrial Productivity

Steel bearings play a vital role in industrial machinery. They can reduce friction and wear. This leads to less frequent replacements. However, it's important to remember that not all steel bearings are created equal. Some may not perform as expected. Regular evaluation of bearing types can greatly impact operational efficiency.

Maintenance downtime is a crucial factor in productivity. Downtime can cost industries significantly. Using high-quality steel bearings can lessen the risk of breakdowns. This translates to longer operational periods. Workers can focus more on their tasks without frequent interruptions. But, if the wrong type of bearing is installed, it can lead to more issues down the line.

While steel bearings improve efficiency, they also demand attention. Regular inspections are required to ensure they function properly. Neglect can lead to serious problems. Operational lapses can arise when organizations assume all is well. It’s essential to maintain a proactive approach. Regular checks can prevent costly breakdowns and ensure minimal downtime.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us