2026 Best Angular Bearing Types and Their Benefits?

In the world of precision engineering, Angular Bearings play a pivotal role. These components bear significant loads with excellent alignment. John Smith, a leading expert in the bearing industry, once noted, “Choosing the right Angular Bearing can drastically improve machinery performance.” His insight reflects the importance of understanding different types and their benefits.

Angular Bearings are especially valued for their ability to handle forces in multiple directions. This feature makes them indispensable in various applications, from automotive to aerospace. However, not all Angular Bearings are created equal. Some designs may outperform others in specific situations. Careful selection is vital for optimal performance.

Industry professionals often overlook some key aspects of Angular Bearings. Many focus solely on the load capacity and ignore lubrication needs. Inadequate maintenance can lead to premature wear and costly failures. It’s essential to address these factors for long-term reliability. The quest for the best Angular Bearing is ongoing, with advancements constantly reshaping the landscape.

Overview of Angular Bearings: Definition and Applications

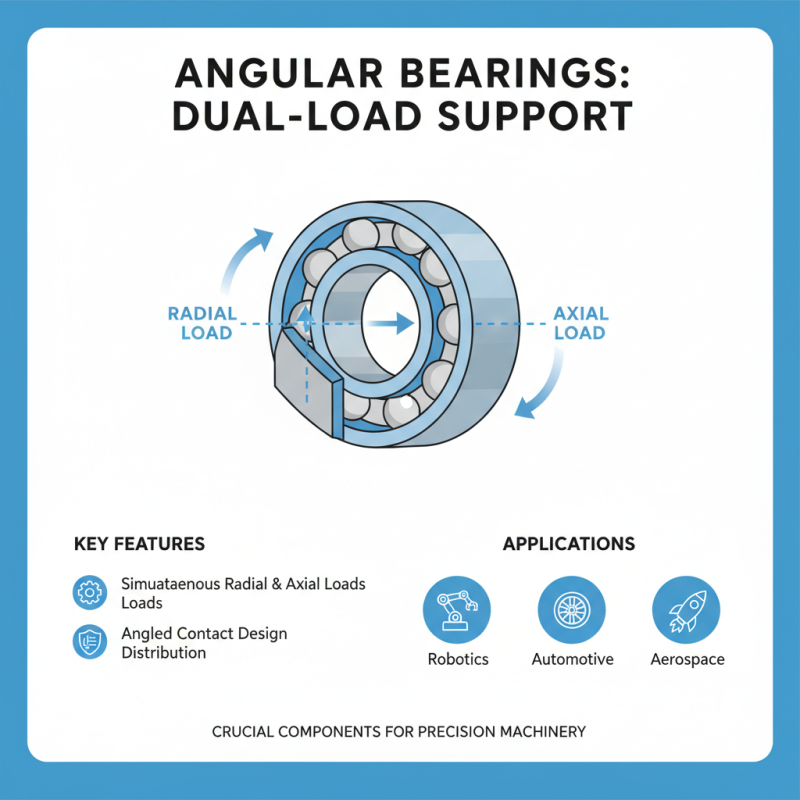

Angular bearings are crucial components in various machinery. They allow for both radial and axial loads to be handled simultaneously. This unique ability makes them suitable for applications such as robotics, automotive, and aerospace. The design features an angle between the inner and outer ring, optimizing load distribution.

When selecting angular bearings, consider the load types. Thrust loads require specific designs to prevent premature wear. Additionally, the choice of materials significantly affects performance. Using high-quality materials can lead to better durability and efficiency.

Tips: Regular maintenance is essential. Inspect bearings for wear and lubrication levels. Early detection of issues can save time and money. Understand the application requirements clearly. This knowledge will guide you in choosing the right bearing type.

Types of Angular Bearings: A Comprehensive Classification

Angular bearings play a crucial role in various applications, including machinery and automotive sectors. These bearings are designed to handle both radial and axial loads. This unique ability makes them suitable for diverse environments. Different types of angular bearings cater to specific needs.

One of the most common types is the single-row angular contact bearing. It can support combined loads but usually requires precise alignment. Its versatility makes it popular in many setups. Double-row angular contact bearings, on the other hand, offer increased load capacity and stability. They can handle higher speeds but may be less forgiving in alignment.

Another noteworthy type is the four-point contact bearing, ideal for applications needing low friction and high stiffness. It tends to handle loads from multiple directions but may wear faster under extreme conditions. When selecting your bearing type, always consider the specific requirements and challenges of your application. Taking time to analyze the load characteristics can lead to better performance.

2026 Best Angular Bearing Types and Their Benefits

| Bearing Type |

Material |

Load Capacity (N) |

Speed Rating (RPM) |

Benefits |

| Angular Contact Ball Bearing |

Steel |

5000 |

25000 |

High axial load capacity and rigidity |

| Double Row Angular Contact Bearing |

Ceramic |

7000 |

20000 |

Increased load capacity and durability |

| Tapered Roller Bearing |

Steel |

10000 |

15000 |

Excellent for heavy radial and axial loads |

| Self-Aligning Ball Bearing |

Plastic |

3000 |

18000 |

Effective in compensating for misalignment |

| Spherical Roller Bearing |

Chrome Steel |

12000 |

12000 |

High load capacity with good shock absorption |

Key Benefits of Using Angular Bearings in Various Industries

Angular bearings are essential components in many mechanical systems. They offer significant advantages across different industries. The unique design allows them to handle both radial and axial loads effectively. This versatility makes them a preferred choice in applications such as automotive, aerospace, and manufacturing.

One key benefit of angular bearings is their increased load capacity. They can support heavier loads while maintaining stability. This is crucial in high-performance environments where precision is vital. Additionally, they excel in high-speed conditions. Their ability to reduce friction leads to smoother operations. However, the installation process can sometimes be tricky and requires careful alignment.

In robotics, for instance, angular bearings enhance movement precision. In heavy machinery, they contribute to increased durability. Yet, their maintenance can be overlooked. Regular inspections and lubrication are necessary. Neglecting these can lead to premature wear. Thus, while angular bearings are beneficial, they still require attention to maintain optimal performance.

Factors to Consider When Choosing Angular Bearings

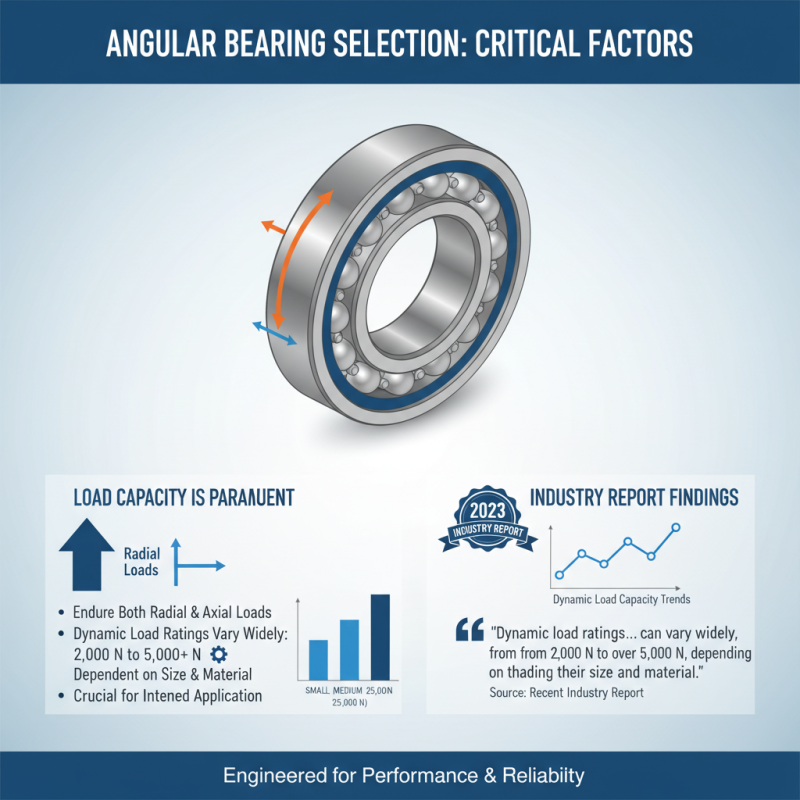

When selecting angular bearings, several critical factors come into play. First, load capacity is paramount. Angular bearings often endure both radial and axial loads. According to a recent industry report, the dynamic load ratings for these bearings can vary widely, from 2,000 N to over 50,000 N, depending on their size and material. This variance is crucial for ensuring the bearing can handle the intended application.

Another aspect to consider is the operating environment. Angular bearings may be exposed to dust, temperature fluctuations, or moisture. Sealed and shielded variants provide different levels of protection. For instance, a study indicated that bearings deployed in harsh environments could have a service life cut by up to 70% if not properly protected. Additionally, lubrication type plays a significant role in performance. While grease is often used, some applications may benefit from oil, especially in high-speed scenarios.

Proper installation and alignment can’t be overlooked. Misalignment often leads to premature wear and failure. Reports suggest that misaligned bearings can reduce lifespan by 50%. End-users must also factor in maintenance schedules. Regular inspections can catch issues early, ensuring the longevity of the system. Each of these factors requires careful consideration to optimize performance and reliability in angular bearing applications.

Maintenance Tips for Maximizing Angular Bearing Lifespan

Proper maintenance of angular bearings is crucial for longevity and efficiency. Regular inspection helps spot wear and tear early. Check for signs of rust or pitting on the surfaces. This visual assessment can reveal underlying issues before they escalate.

Lubrication is key. Use the right type of grease to reduce friction. Over-greasing can cause seal damage, while under-greasing leads to inadequate protection. Find a balance. Changing the lubricant at regular intervals also prevents contamination.

Vibration analysis can be beneficial. It can indicate potential problems before they develop. Remember, even small misalignments can lead to failure. Ensure that the installation is precise to avoid unnecessary wear. Taking these simple steps can significantly enhance the angular bearing's lifespan.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us