2026 Best Radial Ball Bearings for Optimal Performance and Durability?

Radial ball bearings are critical components in various industries, providing both performance and durability. In the competitive landscape of machinery and automotive applications, choosing the right radial ball bearings can significantly impact efficiency. According to a report by the Global Bearings Market, the industry is expected to grow by 6.5% annually through 2026. Despite this promising outlook, selecting the best options remains a challenge for many engineers.

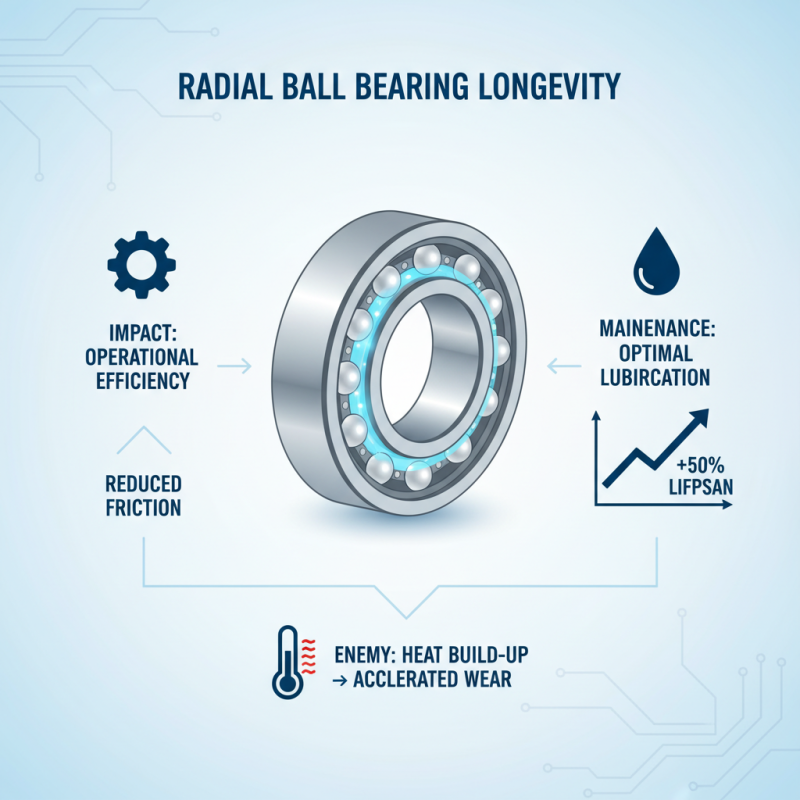

Expert Paul Stevens, a renowned authority in the bearings industry, states, “The longevity of radial ball bearings directly affects overall equipment lifecycle.” However, many users overlook essential factors such as load ratings and lubrication types. This oversight can lead to premature failures and increased maintenance costs. In some sectors, even minor inefficiencies from subpar bearings can escalate operational downtime, highlighting the need for critical evaluation.

While many brands offer radial ball bearings, not all meet rigorous performance standards. Investing in quality bearings demands careful attention to specifications and reviews. As we explore the best radial ball bearings for optimal performance by 2026, we must ask ourselves: Are we choosing wisely or simply settling for what's available?

Overview of Radial Ball Bearings and Their Applications

Radial ball bearings are crucial components in various machinery. Their design allows them to support both radial and axial loads. This makes them versatile in applications from household appliances to large industrial engines. In simple terms, these bearings ensure smooth movement and reduce friction. They are often used in motors, wheels, and conveyor systems.

One interesting aspect is their application in extreme environments. For instance, in high-speed machinery, bearings must withstand heat and pressure. This can lead to wear and tear over time. Regular maintenance is essential to prolong their lifespan. However, many users overlook this. The need for grease or oil changes can be forgotten. This often leads to performance issues that could have been prevented.

In the realm of precision engineering, the quality of radial ball bearings is paramount. Small imperfections can cause significant problems. These include noise and inefficiency in machines. Therefore, choosing the right bearing is critical. Users may sometimes feel overwhelmed by their choices. It’s a reminder to assess needs carefully before selecting components.

Key Features to Consider for Optimal Performance

Choosing the right radial ball bearings is crucial for performance and durability. Key features often define their effectiveness. One important factor is material quality. Steel alloys are common, but ceramic options are increasingly popular. They resist wear better and withstand higher temperatures.

Load capacity also matters. High-load bearings can handle more weight without failing. According to a recent industry report, bearings designed for heavy loads can improve equipment lifespan by 20%. This durability can save considerable repair costs over time.

Another element to consider is lubrication. Proper lubrication reduces friction, enhancing performance. Some bearings feature sealed designs that keep lubrication intact longer than traditional types. However, these seals add complexity. Maintenance can become an issue if seals fail. This necessity for regular inspection cannot be overlooked. Without it, optimal performance is at risk.

2026 Best Radial Ball Bearings for Optimal Performance and Durability

| Model |

Load Rating (kN) |

Speed Rating (RPM) |

Material |

Sealing Type |

Temperature Range (°C) |

| Model A |

20 |

3000 |

Chrome Steel |

Rubber Sealed |

-20 to 120 |

| Model B |

30 |

4000 |

Stainless Steel |

Shielded |

-40 to 150 |

| Model C |

25 |

2500 |

Chrome Steel |

Open |

-30 to 100 |

| Model D |

35 |

4500 |

Ceramic |

Rubber Sealed |

-50 to 200 |

Top Brands of Radial Ball Bearings in 2026

In 2026, the market for radial ball bearings is vibrant. Many top manufacturers are innovating with new technologies. These advancements focus on performance and durability. When considering options, it is crucial to evaluate several brands. Each brand has its strengths and weaknesses.

Some brands have excellent load-bearing capacities but might compromise on noise levels. Others excel in reducing friction but may wear out faster under heavy use. It is essential to analyze these nuances. A bearing that performs well in one application may not suit another. Remember that not all brands offer the same reliability. There are also budget-friendly options that provide decent performance.

Users often overlook maintenance. Regular inspection can prevent failures. A small oversight might lead to major issues down the line. It’s worth noting that personal experiences vary. What works for one user might not work for another. Exploring the reviews and ratings can offer insights but should be taken with caution. Personal trials can yield the best information in such diverse offerings. Choose wisely and reflect on your specific needs for optimal results.

Comparison of Material Types for Durability and Reliability

When it comes to radial ball bearings, the material type plays a crucial role in performance and durability. Common materials include steel, ceramic, and plastic. Steel bearings, the most traditional option, provide high strength and wear resistance. However, they can rust and have limitations in high-temperature environments. According to industry reports, steel can lose up to 50% of its strength at elevated temperatures.

Ceramic bearings offer superior performance in corrosive and high-heat conditions. They are lighter and can withstand higher speeds. However, they tend to be more brittle. A study highlights that ceramic bearings can last 5-10 times longer than their steel counterparts under optimal conditions. For applications requiring low weight and less friction, plastic bearings serve well, but they may lack the durability needed for heavy loads.

Tip: Regularly inspect bearings for wear. Small cracks can lead to premature failure.

Another consideration is lubrication. Proper lubrication can significantly enhance the lifespan of bearings. Reports suggest that up to 90% of bearing failures are due to inadequate lubrication. Choosing the right type and amount of lubricant affects performance directly.

Tip: Consider the environment when choosing lubrication methods. Some lubricants may not perform well at extreme temperatures.

Maintenance Tips for Longevity of Radial Ball Bearings

Radial ball bearings are vital components in various machines. Their performance directly affects operational efficiency. To maximize their longevity, regular maintenance is crucial. According to industry reports, maintaining optimal lubrication can increase bearing lifespan by up to 50%. Proper lubrication reduces friction, preventing heat build-up. Heat is often a silent enemy that accelerates wear.

Cleaning is another key factor. Dust and contaminants can drastically alter performance. Studies show that even minor contamination can lead to premature failure. Implementing regular cleaning routines can mitigate this risk. It's a simple step that can yield significant benefits. Regular inspection helps detect potential issues early. Look for signs of wear or rust. These small observations can save time and money in the long run.

Lastly, be mindful of the environment. Operating conditions impact bearing performance. High temperatures or moisture can significantly reduce their lifespan. Monitoring these factors is essential. The right conditions can enhance functionality, while neglect can lead to early replacement. Remember, a small oversight can lead to significant problems. Regular attention is necessary for optimal performance and durability.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us