How to Choose the Best Agricultural Bearings for Maximum Efficiency

When it comes to maximizing efficiency in agricultural machinery, the choice of Agricultural Bearings is crucial. According to a report by the Global Agricultural Bearings Market, the demand for these specialized components is projected to grow by 5.6% annually, driven by advancements in farming techniques and the increasing need for high-performance equipment. Effective bearings not only enhance the longevity and reliability of machinery but also reduce maintenance costs and downtime, which are vital for maintaining operational efficiency in modern agriculture. As farmers and equipment manufacturers seek optimal solutions, understanding the alternatives available in the agricultural bearings market can lead to informed decisions that improve productivity and profitability.

Understanding the Role of Agricultural Bearings in Modern Farming Practices

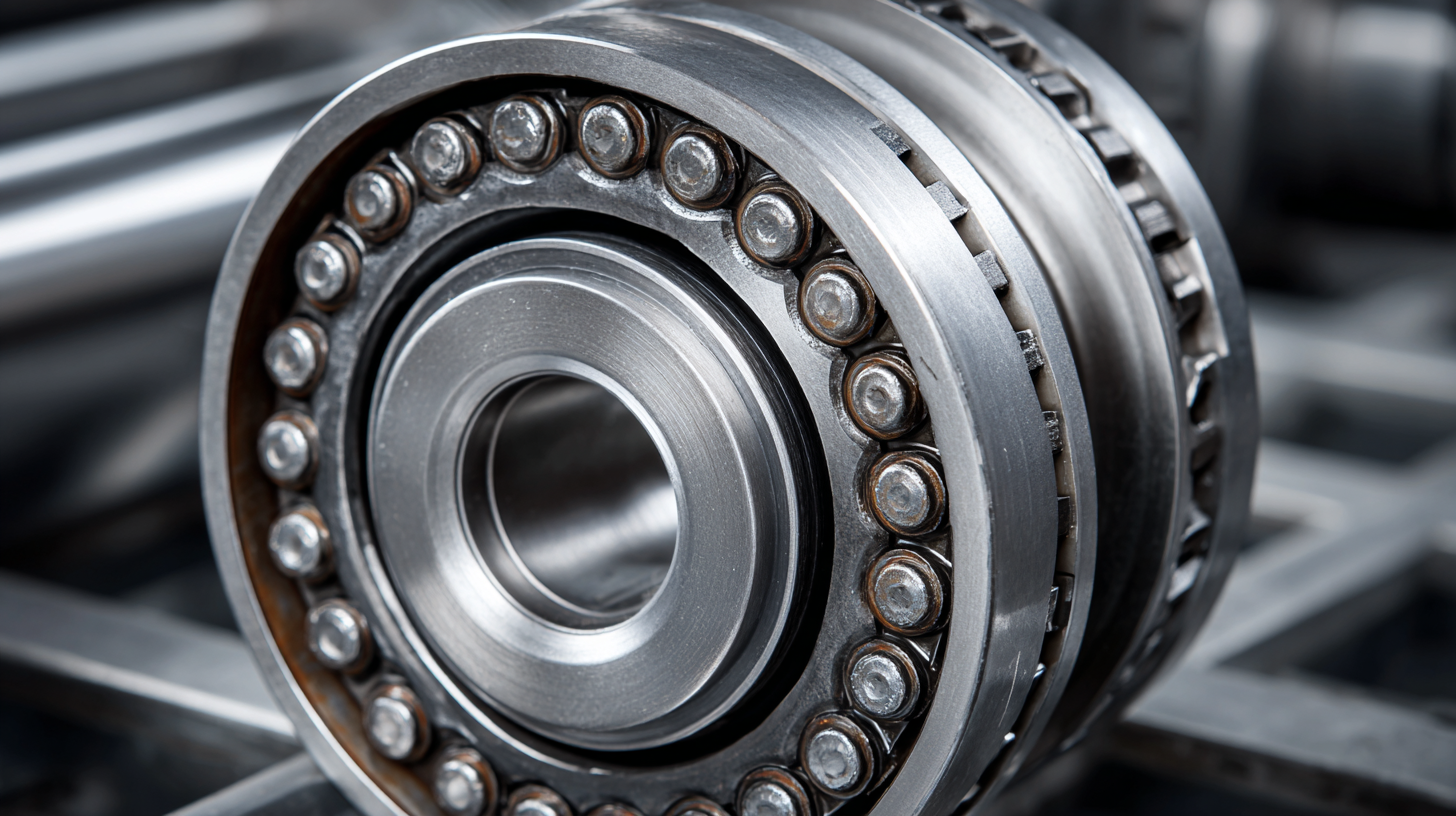

In modern farming practices, agricultural bearings play a crucial role in ensuring the smooth operation of machinery and equipment. These specialized components are designed to withstand the harsh conditions often encountered in the agricultural sector, such as exposure to dust, moisture, and varying temperatures. Their primary function is to reduce friction between moving parts, allowing for more efficient energy use and longer operational lifespans for equipment like tractors, harvesters, and irrigation systems.

Choosing the right agricultural bearings can significantly impact the overall efficiency of farming operations. It is essential to consider factors such as load capacity, speed ratings, and environmental conditions when selecting bearings. For instance, sealed bearings can offer superior protection against contaminants, while high-load bearings might be necessary for heavier machinery. By understanding the specific requirements of their equipment and the working conditions, farmers can optimize their choice of bearings, leading to reduced downtime and maintenance costs, ultimately enhancing productivity and profitability in their operations.

Key Factors to Consider When Selecting Agricultural Bearings for Your Equipment

When selecting agricultural bearings for your equipment, several key factors play a crucial role in ensuring maximum efficiency. First and foremost, consider the load capacity. Agricultural machinery often operates under heavy loads and varying conditions. Therefore, it is essential to choose bearings that can withstand specific loads while maintaining optimal performance. Look for bearings designed with high load ratings, as they are engineered to handle the rigorous demands of farming tasks.

Another critical factor is the bearing material. Different agricultural applications present unique challenges such as exposure to dirt, moisture, and extreme temperatures. Bearings made from stainless steel or specialized composites are excellent choices for preventing corrosion and extending lifespan. Additionally, consider the bearing's lubrication system; sealed or shielded bearings can reduce maintenance needs and enhance longevity by keeping contaminants out, thereby ensuring smoother operation under harsh conditions. Selecting the right combination of load capacity and material ensures that your agricultural equipment operates effectively and efficiently, maximizing productivity on the farm.

Efficiency of Different Agricultural Bearings

Comparing Different Types of Agricultural Bearings for Optimal Performance

When choosing agricultural bearings, it’s essential to compare the various types available to ensure optimal performance for your specific machinery. Agricultural operations often encounter challenging conditions, including exposure to dust, moisture, and varying temperatures. Thus, selecting bearings designed for resilience, like sealed or shielded ball bearings, can significantly enhance durability and reduce maintenance costs.

Another key factor is the size and load capacity of the bearings. For heavy-duty applications, tapered roller bearings are ideal as they can handle both radial and axial loads effectively. On the other hand, spherical roller bearings provide flexibility and can accommodate misalignment, making them suitable for less precise applications. Ultimately, understanding the operational requirements and the specific challenges your machinery faces is crucial when comparing different types of agricultural bearings. Choosing the right type will not only improve efficiency but also prolong the lifespan of your equipment.

How Quality Bearings Can Enhance the Longevity of Agricultural Machinery

When it comes to agricultural machinery, the significance of quality bearings cannot be overstated. Bearings are fundamental components that allow machines to operate with efficiency and reliability, reducing wear and tear and ultimately extending the life of the equipment. By investing in high-quality bearings, farmers not only ensure the smoother operation of their machinery but also minimize downtime, which is critical during peak operational seasons. Effective bearing solutions can translate to substantial cost savings over time, enhancing productivity and efficiency in agricultural operations.

The agricultural sector is witnessing a notable expansion in the ball bearing market, predicted to experience a CAGR of over 7.34% up to 2032. This growth highlights the increasing recognition of the importance of durable and efficient bearing systems in the industry. Manufacturers are responding to this demand by expanding their lines of aftermarket products, including bearings specifically designed for agricultural applications. As these innovations come to market, they further enhance the longevity of machinery, providing farmers with reliable solutions that contribute to sustained agricultural output and reduced maintenance challenges.

Tips for Proper Maintenance of Agricultural Bearings to Maximize Efficiency

Proper maintenance of agricultural bearings is crucial for maximizing efficiency and extending the lifespan of your machinery. One of the fundamental practices is to ensure that bearings are adequately lubricated. Regularly check the lubrication levels, as insufficient grease can lead to increased friction and eventual failure. Additionally, consider using high-quality lubricants that are specifically designed for agricultural environments, which can withstand heavy loads and temperature variations.

Moreover, it’s vital to inspect bearings for signs of wear and damage. This includes looking for pitting, discoloration, or unusual noises during operation. Implementing a routine inspection schedule can help detect issues early, allowing for timely repairs or replacements before they escalate into more significant problems. Cleaning the bearings and their housing regularly to remove dirt and debris will also prevent contamination, further enhancing performance. By staying proactive in maintenance, you ensure that your agricultural machinery operates at peak efficiency, contributing to overall productivity on the farm.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us