2025 How to Choose the Best Bearing Tools for Your Projects

In the realm of engineering and manufacturing, the selection of appropriate bearing tools is crucial for ensuring operational efficiency and product longevity. According to a recent market analysis by Global Industry Analysts, the global bearing tools market is poised to reach USD 125 billion by 2025, reflecting a significant growth rate influenced by the increasing demand across various sectors, including automotive and aerospace. Bearing tools play an essential role in the performance and durability of machinery, making the choice of the right type imperative for both industrial and DIY projects.

As the complexity of mechanical systems evolves, so does the technology behind bearing tools. Advanced materials and manufacturing processes are now available, which can enhance the longevity and reliability of bearings. The International Organization for Standardization (ISO) highlights that choosing the right bearing tool can reduce maintenance costs by up to 30%, a key factor for businesses looking to optimize operational costs. With the rapid pace of technological advancements, understanding how to select the best bearing tools tailored to specific project requirements is more important than ever for professionals in the field.

Understanding Different Types of Bearing Tools and Their Uses

When selecting bearing tools for your projects, it’s crucial to understand the different types available and their specific uses. Bearing tools can generally be categorized into several types, including bearing pullers, installation tools, and polishing tools. Bearing pullers are essential for safely and efficiently removing bearings from shafts and housings, minimizing the risk of damage. They come in various designs, such as three-arm and two-arm pullers, each suited for different kinds of bearings and space constraints.

Installation tools, on the other hand, ensure that bearings are mounted correctly without causing any wear or damage during the process. Proper alignment and friction management are essential for the longevity of the bearing, making tools like bearing drivers or presses valuable additions to any toolkit. Additionally, polishing tools are designed to enhance the smoothness of bearing surfaces, improving performance and reducing friction over time. By understanding these different types of bearing tools and their applications, you can make informed decisions that will contribute to the success of your projects.

Key Factors to Consider When Selecting Bearing Tools for Projects

When selecting bearing tools for projects, it is crucial to consider several key factors to ensure optimal performance and longevity. According to a report by the International Organization for Standardization (ISO), approximately 50% of mechanical failures are attributed to incorrect tool selection and maintenance. Therefore, evaluating the specific requirements of your project, such as load capacity, speed, and environmental conditions, plays a vital role in making an informed decision. Additionally, understanding the type of bearings needed, whether ball, roller, or plain bearings, can significantly impact both efficiency and durability.

When assessing bearing tools, it’s also essential to factor in the material compatibility. Tools made from high-quality steel or ceramic materials tend to offer better resistance to wear and corrosion, contributing to longer service life and reduced maintenance costs. The American Society of Mechanical Engineers (ASME) indicates that using the right material can enhance tool performance by up to 25%.

**Tips:** Always consult detailed technical specifications and application guidelines provided by experienced manufacturers in the field. Additionally, performing regular audits on tool performance can prevent unexpected project delays and ensure equipment reliability. By prioritizing these elements, you can enhance the efficiency and success rate of your projects while optimizing resource use.

2025 How to Choose the Best Bearing Tools for Your Projects - Key Factors to Consider When Selecting Bearing Tools for Projects

| Factor |

Description |

Importance Level |

| Type of Bearing |

Choose based on the load, speed, and application requirements. |

High |

| Size and Compatibility |

Ensure the bearing fits the assembly properly. |

High |

| Material Quality |

Select materials that can withstand the working environment. |

High |

| Load Capacity |

Consider the maximum load the bearing needs to handle. |

Medium |

| Speed Rating |

Ensure the bearing can operate at the necessary RPM. |

High |

| Cost |

Balance between quality and budget constraints. |

Medium |

| Supplier Reputation |

Consider reliability and feedback from other customers. |

Medium |

| Maintenance Requirements |

Determine ease of maintenance and availability of support. |

Low |

Evaluating Quality and Durability of Bearing Tools for Longevity

When selecting bearing tools for your projects, evaluating the quality and durability of these tools is essential to ensure they provide the longevity needed for effective performance. High-quality materials, such as hardened steel or chrome vanadium, are often indicative of a tool's capability to withstand wear and tear during heavy use. Checking for coatings that enhance resistance to corrosion can also be a vital indicator of a tool's durability, particularly in environments where moisture or harsh chemicals are present.

Additionally, construction quality plays a major role in the longevity of bearing tools. Tools that feature precision machining and robust design are less likely to fail under pressure. Features such as heat treatment can improve tool toughness, while ergonomic designs can provide better grip and control, further preventing premature wear. It's also important to assess warranty offerings, as a longer warranty often reflects the manufacturer's confidence in the reliability and durability of their products. By focusing on these aspects, you can make informed decisions that will benefit your projects in the long run.

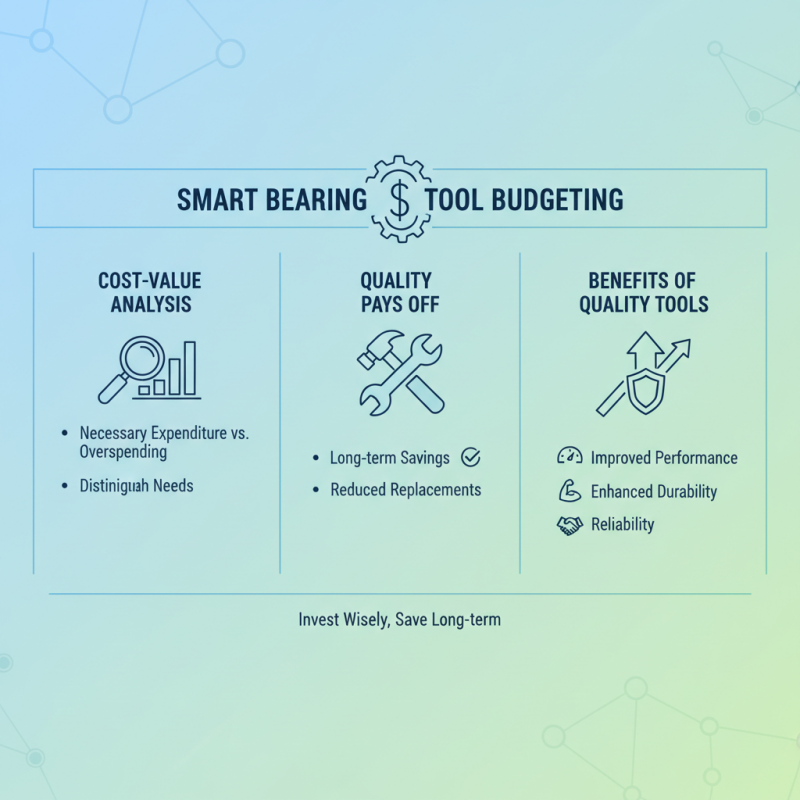

Budgeting for Bearing Tools: Cost vs. Value Analysis

When embarking on projects that require bearing tools, budgeting becomes a crucial aspect of your planning. An effective cost vs. value analysis will help you distinguish between necessary expenditures and potential overspending. While it might be tempting to opt for the cheapest options, understanding the long-term benefits of quality tools can save you money and time in the long run. High-quality bearing tools often offer better performance, durability, and reliability, reducing the likelihood of premature replacement or failure.

Tips for successful budgeting include researching various options and seeking tools that offer a balance between price and quality. Consider purchasing tool sets that meet multiple needs, as they can provide greater value per unit. Additionally, evaluate any warranties or customer support offered, as these can add significant value to your investment. Investing in tools that come with reliable support might cost a bit more upfront, but it ensures peace of mind and longevity in your projects.

Another critical point to remember is to assess your specific project needs carefully. Not every project will require a full suite of tools, so prioritize based on what is essential. This focused approach not only assists in managing your budget but also helps you allocate funds toward more specialized or higher-quality tools where necessary.

Maintenance and Care Tips for Extending the Life of Bearing Tools

Maintaining and caring for your bearing tools is essential for extending their lifespan and ensuring optimal performance. Regular maintenance not only helps to identify potential issues early but also increases efficiency in your projects. One effective tip is to clean your tools after each use. Grit and grime can accumulate, leading to wear and tear. Use a soft brush or cloth to remove debris, and consider using a mild solvent if necessary.

Another key aspect of maintenance is lubrication. Bearings require proper lubrication to minimize friction and wear. Make it a habit to check the lubrication levels periodically and apply the recommended lubricant to ensure smooth operation. It’s also important to store your bearing tools in a dry, well-ventilated area to prevent rust and corrosion. Always protect them with a cover or case to shield them from dust and moisture when not in use.

Additionally, inspect your tools regularly for any signs of damage or wear. Look for cracks or deformities in the bearings, as these can significantly affect their performance. Addressing minor issues before they escalate can save you time and expense in the long run. By following these maintenance and care tips, you can help your bearing tools last longer and perform better on all your future projects.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us