How to Choose the Best Agricultural Bearings for Your Farming Needs

Choosing the right Agricultural Bearings is crucial for effective farming. These components are essential for the machinery that drives productivity. They support rotating parts, ensuring smooth operations. Selecting the wrong bearing can lead to costly downtime and repairs.

When evaluating Agricultural Bearings, consider the specific requirements of your equipment. Operating conditions such as dust, humidity, and temperature must be factored in. A bearing that excels in one environment may falter in another. It's vital to understand the balance between cost and durability. Sometimes, cheaper options can lead to frequent replacements, which may not be wise in the long run.

Farmers often overlook the importance of routine maintenance. Ignoring this can result in premature bearing failure. Recognizing the signs of wear and tear is essential. Regular checks can help prevent catastrophic breakdowns. Always remember, the success of your farming equipment hinges on the quality of Agricultural Bearings you choose. Reflecting on your past choices can guide you to better decisions in the future.

Understanding Agricultural Bearings and Their Importance in Farming

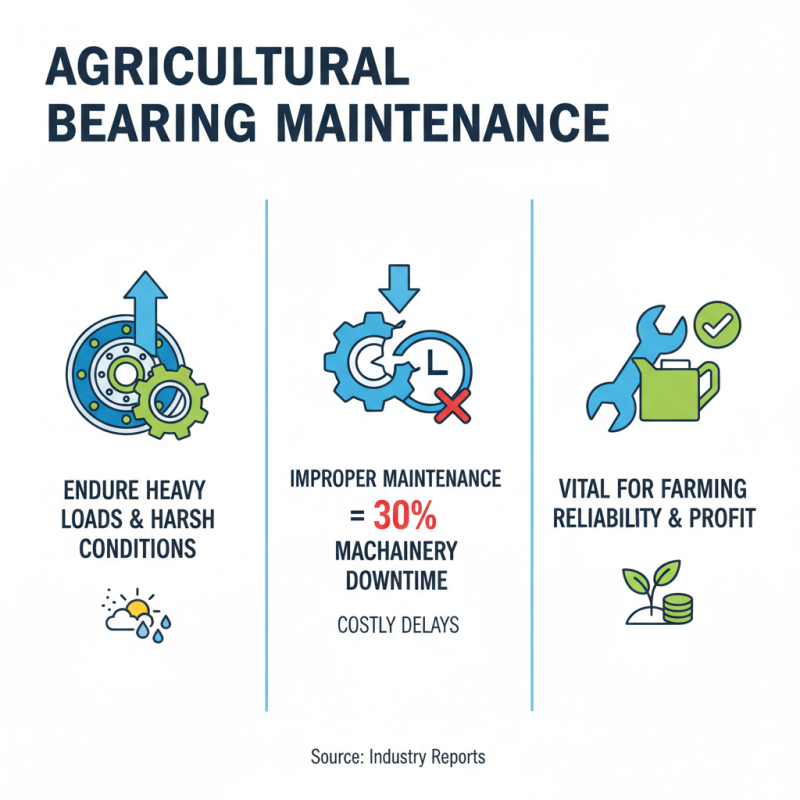

Agricultural bearings play a critical role in farming operations. These components endure immense pressures and harsh conditions. They support machinery like tractors, plows, and harvesters. According to a 2022 industry report, the demand for agricultural bearings grew by 8% globally. This increase highlights their essential role in enhancing equipment efficiency.

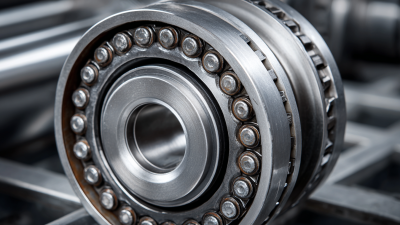

Understanding the types of bearings is vital. There are different designs, including ball bearings and roller bearings. Each type has unique advantages. For instance, roller bearings provide better load capacity. However, they can be more sensitive to misalignment. This sensitivity can lead to failures and costly repairs. A report from the International Agricultural Machinery Association indicates that improper bearing selection raises maintenance costs by up to 15%.

Farmers often overlook the importance of regular maintenance. Bearings require proper lubrication to function efficiently. A lack of lubrication can cause premature wear and tear. Industry statistics suggest that nearly 30% of bearing failures are due to inadequate maintenance. Recognizing these issues is crucial for optimizing productivity on the farm. Such insights can lead to better investment decisions in equipment and maintenance practices.

Understanding Agricultural Bearings and Their Importance in Farming

Types of Agricultural Bearings: An Overview of Options Available

When exploring agricultural bearings, it's essential to understand the various types available. Ball bearings are common due to their versatility and ability to handle radial and axial loads. They are perfect for rotating equipment like tractors and harvesters. Another option is roller bearings, which are known for their high load capacity. These are suitable for applications that involve heavy loads, such as large agricultural machinery.

In addition to these, there are specialized options. Slewing bearings are ideal for equipment that requires rotation. Farmers often use them in machinery like loaders and excavators. A less common choice is magnetic bearings, which don't require lubrication. They reduce friction but can be expensive and tricky to maintain. It's crucial to assess the specific needs of your equipment before deciding on a bearing type.

Choosing bearings isn't a straightforward task. There is no one-size-fits-all solution. Sometimes, farmers may choose a bearing that’s too heavy for lighter equipment. This can lead to increased wear and tear. Others might overlook environmental conditions, like moisture exposure, which affects bearing longevity. Each choice demands careful consideration and reflection. Balancing quality with cost often presents a challenge.

How to Choose the Best Agricultural Bearings for Your Farming Needs

| Bearing Type |

Material |

Load Capacity (kg) |

Temperature Range (°C) |

Application |

| Deep Groove Ball Bearing |

Chrome Steel |

900 |

-30 to 120 |

General Farming Equipment |

| Tapered Roller Bearing |

Alloy Steel |

1500 |

-20 to 150 |

Trailers and Loadbearing Equipment |

| Self-Aligning Ball Bearing |

Stainless Steel |

750 |

-40 to 120 |

Application with Misalignment |

| Spherical Roller Bearing |

Copper Alloy |

2000 |

-30 to 160 |

Heavy Machinery |

| Needle Bearing |

Polyamide |

600 |

-30 to 100 |

Compact Spaces |

Key Factors to Consider When Selecting Agricultural Bearings

Choosing the right agricultural bearings is crucial for optimal farm performance. Start by considering the environment. Bearings must withstand dust, dirt, and moisture. Select materials that resist corrosion and wear. Depending on your location, climate can heavily influence your choice.

When sizing the bearings, it’s important to match them to your equipment specifications. Mismatched sizes lead to failures. Check load capacity and speed ratings as well. Overloading bearings can result in breakdowns.

**Tips:** Always take maintenance into account. Regular inspections can reveal issues early. Look for signs of wear or unusual noises. Consider the ease of replacement. Complicated setups can hinder timely repairs. Stay informed about technological advancements. Some new designs may offer improved performance and longevity.

Common Mistakes to Avoid in Choosing Agricultural Bearings

Choosing agricultural bearings requires careful consideration to avoid common mistakes. Many farmers overlook load ratings. Selecting a bearing with an inadequate load rating can lead to premature failure. Research indicates that over 50% of bearing failures in agricultural settings stem from improper load calculations. It's crucial to match the bearing with the equipment's weight and operational demands.

Another common error is ignoring environmental factors. Bearings must withstand dirt, moisture, and temperature fluctuations. Failing to consider these can result in increased wear and tear. According to industry reports, 30% of bearing issues relate to environmental conditions. Farmers should opt for bearings specifically designed for harsh conditions. Keeping lubrication in mind is also essential. Inadequate lubrication can lead to significant performance issues.

Often, farmers also rush their selection process. This haste can lead to incorrect sizes or types. A detailed assessment of current needs and future growth is vital. It’s essential to consult with professionals to make informed decisions. Taking these steps can help prevent costly mistakes and ensure efficient farming operations.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us