Why Choose Radial Ball Bearings for Your Applications?

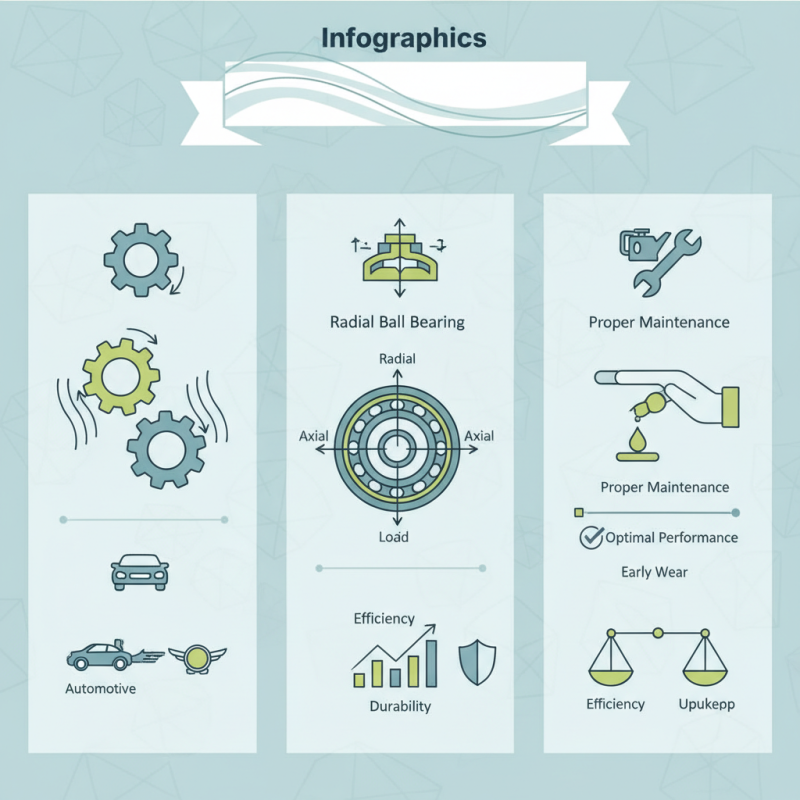

In the world of mechanical applications, Radial Ball Bearings play a crucial role. They provide support and reduce friction in rotating parts. Various industries rely on them for their efficiency and durability.

These bearings feature a unique design, allowing for the smooth operation of machinery. Their versatility makes them suitable for diverse applications, from automotive to aerospace. However, selecting the right type can be challenging. Some may overlook specifics that could enhance performance.

Understanding the benefits of Radial Ball Bearings is vital. They offer low rolling resistance and can handle both radial and axial loads. Despite their advantages, they require proper maintenance. Neglecting this aspect may lead to early wear and tear. It’s essential to recognize the balance between efficiency and upkeep for optimal performance.

Advantages of Radial Ball Bearings in Mechanical Applications

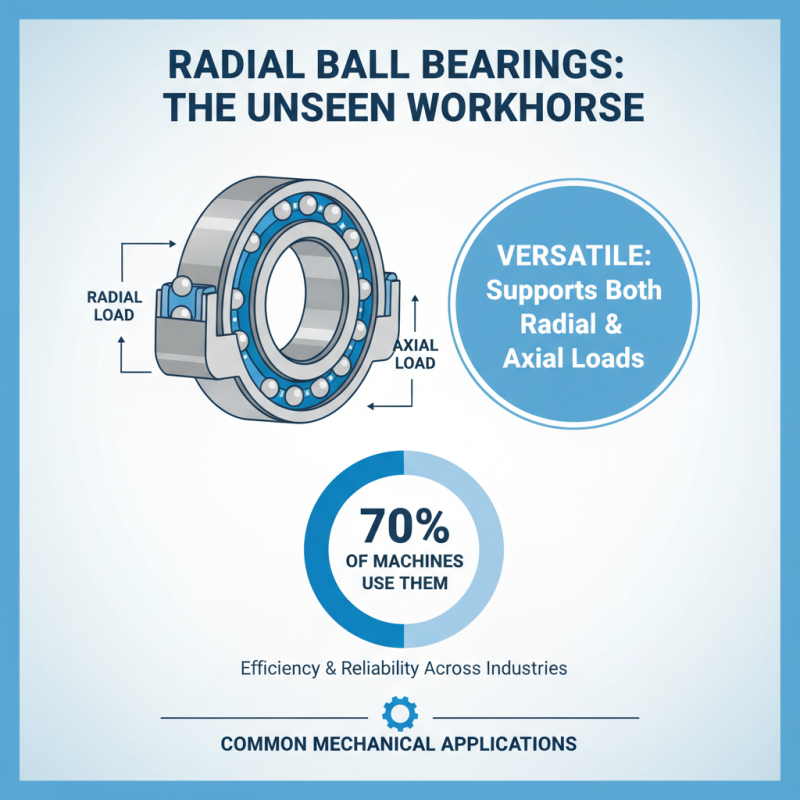

Radial ball bearings are commonly used in various mechanical applications due to their unique advantages. They have the ability to support both radial and axial loads, making them quite versatile. Research shows that about 70% of machines utilize these bearings. This wide usage is a testament to their efficiency and capability.

One of the main advantages of radial ball bearings is their low friction. According to the American Bearing Manufacturers Association, these bearings can reduce friction by up to 30% compared to traditional designs. This lower friction leads to improved energy efficiency. Therefore, manufacturers can save on operational costs. However, it is crucial to note that improper installation can result in increased wear, counteracting these benefits.

Additionally, radial ball bearings are typically lightweight. This characteristic is essential for applications like electric motors and fans. The weight savings can enhance overall performance. Yet, there are challenges with heat management. Overheating can shorten the lifespan of these bearings. Users must monitor operational conditions closely to avoid failures. Balancing the benefits and potential limitations is key to effective implementation.

Comparative Analysis: Radial Ball Bearings vs. Other Bearing Types

Radial ball bearings are popular choices for many applications. They offer excellent versatility and load-handling capabilities. When comparing them to other types, such as thrust bearings, the differences become clear. Thrust bearings excel in handling axial loads, but their radial limitations may restrict their use in certain setups. Radial ball bearings can accommodate both radial and axial loads, making them more adaptable in many situations.

In applications requiring high speeds, radial ball bearings shine bright. Their design minimizes friction, allowing smoother motion. In contrast, sleeve bearings, while stable, tend to generate more heat, which may lead to premature wear. Yet, radial ball bearings are not without flaws; they may require more frequent lubrication compared to some sealed alternatives. Users should consider this maintenance aspect.

Another point of reflection lies in the size options available. Radial ball bearings come in a range of dimensions, offering flexibility for various machines. However, this variety can complicate selection. Choosing the right size is crucial for optimal performance. Overly large bearings may add unnecessary weight, while undersized ones risk failure. Awareness of these details is key in bearing selection.

Factors to Consider When Selecting Radial Ball Bearings

When selecting radial ball bearings, several factors come into play. The load capacity is crucial. It determines how much weight the bearing can handle. Make sure the bearing meets the specific load requirements of your application. An underestimated load can lead to failure over time.

Another important factor is the speed limit. Bearings are rated for specific speeds. Exceeding these limits can cause overheating. This often results in premature wear or even damage. Assess the operating conditions to avoid such issues.

Additionally, consider the environment where the bearings will operate. Dust, moisture, and extreme temperatures can affect performance. The right choice ensures longevity and reliability. Take time to evaluate your needs. It may save costs and prevent future headaches.

Factors Affecting the Selection of Radial Ball Bearings

Common Applications Utilizing Radial Ball Bearings

Radial ball bearings are essential in various industries. They minimize friction and support heavy loads. This makes them ideal for applications such as automotive engines, electric motors, and household appliances. In vehicles, they enable smooth rotations of wheels and gears. They withstand high temperatures and pressures, which is crucial for engine performance.

In manufacturing, radial ball bearings play a crucial role in machinery. They enhance the efficiency of conveyor systems and robotic arms. These bearings occupy less space while providing high performance. However, improper installation can lead to premature wear. Regular maintenance is required to avoid unexpected breakdowns.

Their use in household appliances, like washing machines, is quite common. Bearings ensure quiet and efficient operation. Unfortunately, many people overlook them. This can lead to costly repairs. Designing effective applications requires understanding the right specifications. It’s important to match the bearing type with the task.

Maintenance Practices for Longevity of Radial Ball Bearings

Maintaining radial ball bearings is crucial for optimal performance. Regular lubrication is vital. The right lubricant prevents wear and extends the lifespan of the bearings. Studies indicate that proper lubrication can enhance bearing lifespan by up to 50%. Selecting the correct lubricant type based on temperature and load conditions is essential. Using incompatible lubricants can lead to premature failure.

Monitoring operating conditions is another key practice. Overheating can drastically reduce bearing efficiency. A 2021 industry report suggested that 30% of bearing failures arise from overheating. Other factors include contamination and misalignment. Regular inspections help catch these issues early. Clean environments significantly reduce debris accumulation.

Another area needing attention is load management. Overloading bearings affects their functionality. It’s reported that more than 40% of bearings fail due to excessive loads. Keeping loads within recommended limits is critical. It might seem straightforward, yet many overlook this. Regular training for operators can help reinforce proper practices. Small adjustments, like reducing load by just 10%, can lead to substantial longevity gains.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us