How to Choose Radial Ball Bearings for Your Machinery Needs?

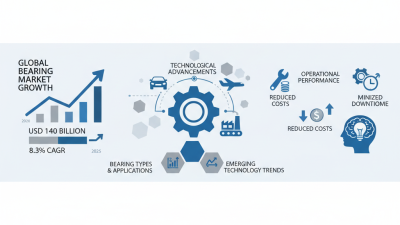

Choosing the right Radial Ball Bearings is crucial for machinery efficiency. These components play a significant role in reducing friction, ensuring smooth operation. According to a report by Smithers Pira, the global bearing market is expected to reach $78 billion by 2025. This highlights the growing demand for high-quality bearings in various industries.

Manufacturers must consider multiple factors when selecting Radial Ball Bearings. Load capacity, speed ratings, and environmental conditions are vital. A bearing that doesn't match the machinery requirements can lead to failures. Indeed, a 2021 study by the International Journal of Engineering Research indicated that 30% of machinery breakdowns stem from improper bearing choices.

The selection process can be challenging. Each application is unique, requiring tailored solutions. Sometimes, engineers overlook customization options, leading to inefficiencies. It's important to reflect on the specific needs of each operation. Making informed choices concerning Radial Ball Bearings can significantly enhance performance and extend machinery lifespans.

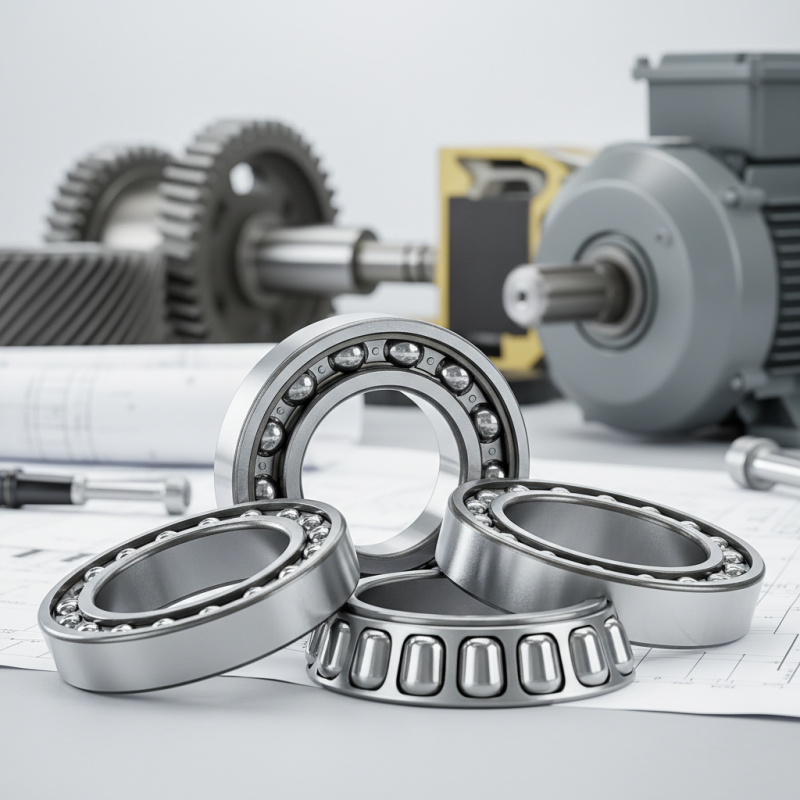

Understanding the Basics of Radial Ball Bearings and Their Function

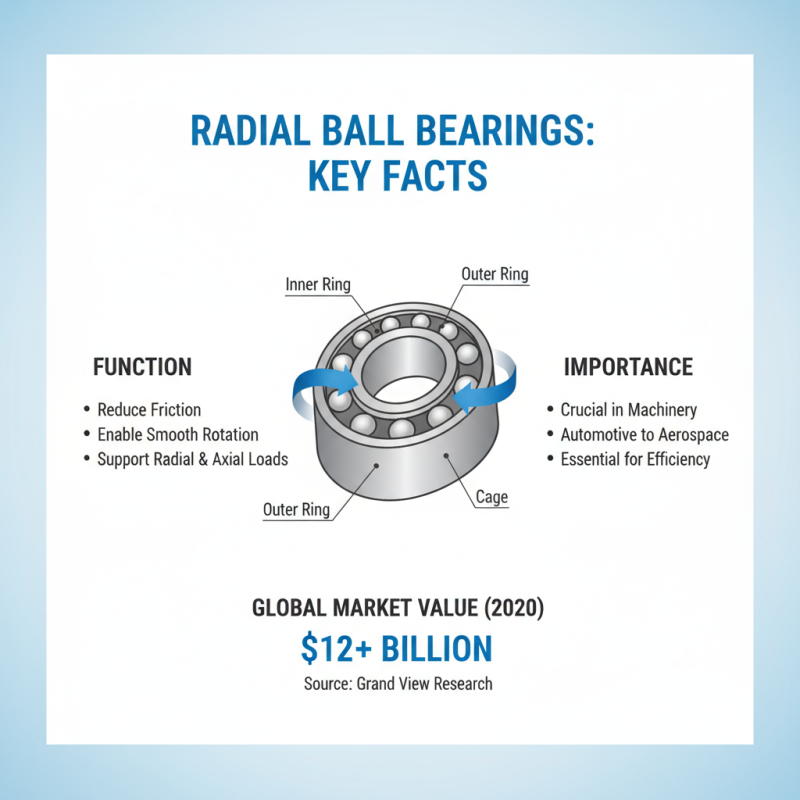

Radial ball bearings play a crucial role in the functioning of various machinery. They reduce friction between moving parts by allowing parts to rotate smoothly. A basic understanding of these components is essential for selecting the right bearing for your needs. According to a report by Grand View Research, the global ball bearing market was valued at over $12 billion in 2020, demonstrating their importance across various industries.

These bearings are designed to support radial loads and some axial loads. With the right specifications, they can enhance the efficiency of machinery. However, not all radial ball bearings are created equal. Factors such as material, load rating, and operating environment must be considered carefully. A simple oversight, such as underestimating load capacity, can lead to early bearing failure. In fact, it is reported that improper bearing selection can cause failures in up to 40% of machinery breakdowns, highlighting the critical importance of informed choices.

Choosing radial ball bearings requires attention to detail. One must look beyond initial specifications. Consider the application and the conditions under which the bearings will operate. Higher temperatures or corrosion-prone environments will impact bearing life. Reviewing technical data sheets remains essential. Yet, even with ample information, making a mistake due to oversight is all too common. Always reflect on what could go wrong.

Identifying Key Factors for Selecting Radial Ball Bearings

Choosing the right radial ball bearings for machinery can be tricky. It's vital to identify key factors during the selection process. A common mistake is underestimating the operating conditions. Consider the temperature, humidity, and contamination levels. Each of these factors influences bearing performance.

Tip: Always check the load ratings of the bearings. This rating indicates how much weight they can handle effectively. Selecting an inappropriate load rating leads to early failures.

Another key factor is the speed of operation. Bearings are designed for specific speed ranges. If you exceed these limits, it can cause overheating. It’s essential to know your machinery's requirements.

Tip: Evaluate the lubrication options. Proper lubrication reduces friction and extends bearing life. Forgetting this step is a common oversight. Lack of maintenance can lead to costlier repairs down the line. Take time to assess each aspect carefully.

How to Choose Radial Ball Bearings for Your Machinery Needs? - Identifying Key Factors for Selecting Radial Ball Bearings

| Key Factor |

Description |

Importance Level |

Common Applications |

| Load Capacity |

The maximum load the bearing can support without deformation. |

High |

Industrial machinery, automotive applications |

| Speed Rating |

The maximum rotational speed under which the bearing can operate reliably. |

Medium |

Electric motors, fans |

| Material |

The composition of the bearing which affects wear resistance and durability. |

High |

Pumps, conveyors |

| Sealing Type |

The type of seals that protect the bearing from contamination. |

Medium |

Gearboxes, agricultural machinery |

| Temperature Range |

The operating temperature limits for reliable performance. |

Medium |

HVAC systems, industrial ovens |

| Lubrication Type |

The method used to apply lubrication to the bearing. |

High |

Automobiles, machinery |

Evaluating Load Capacity and Performance Specifications

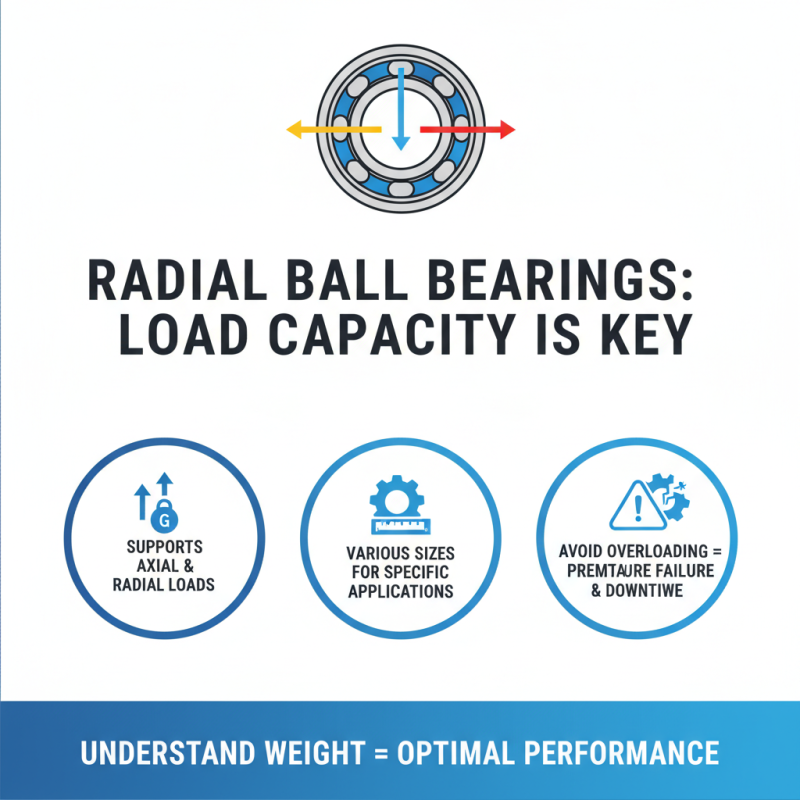

When selecting radial ball bearings, load capacity is crucial. These bearings support axial and radial loads. They come in various sizes, each designed for specific applications. Understanding the weight your machinery will endure is essential before making a choice. Overloading could lead to premature failure, causing costly downtimes.

Performance specifications matter, too. Look for details like speed ratings and temperature limits. High-speed applications require bearings that can withstand friction and heat. However, not all bearings can handle extreme conditions. This doesn’t mean you should avoid high-temperature environments but be cautious. Every choice comes with trade-offs. It’s essential to weigh these factors before deciding, as each machinery need is unique.

Assessing the Impact of Material and Coating on Durability

When selecting radial ball bearings, material and coating play a crucial role in durability. Bearings made from high-carbon chromium steel, for instance, often exhibit enhanced fatigue life. According to a report by the American Society of Mechanical Engineers, this type of steel can extend bearing life by up to 30%. This is particularly significant for high-load applications.

Additionally, surface coatings can further improve performance. Hard coatings, such as ceramic or titanium nitride, increase wear resistance. Research shows that coatings can reduce friction loss by 20%, which contributes to lower operating temperatures. However, the choice of coating must align with specific application environments. Not all coatings are suitable for extreme conditions.

It's important to note that even with superior materials and coatings, factors like lubrication and installation also impact longevity. Some users overlook these elements. They may invest in the best bearings, yet fail to maintain them properly. Regular monitoring and maintenance are essential, as neglect can lead to premature failure. Balancing material choice and operational care is key to achieving optimal results.

Exploring Maintenance Tips for Maximizing Bearing Lifespan

Maintaining radial ball bearings is crucial for machinery performance. Proper maintenance maximizes their lifespan and efficiency. Regular inspections are essential. Check for signs of wear or damage. Look for unusual sounds or vibrations during operation. These could indicate potential issues needing attention.

Lubrication plays a key role in bearing health. Use the correct grease or oil, as specified for your machinery. Over-lubrication can cause excess heat. Under-lubrication may lead to increased friction and wear. Ensure lubrication intervals match your operating conditions. Environmental factors can affect the frequency of maintenance tasks.

Cleaning is another vital step. Dust and debris can compromise bearing performance. Use appropriate cleaning methods to remove contaminants. Avoid harsh solvents that could damage seals or surfaces. Remember that sometimes you might overlook these processes. Reflect on your routine and adjust as necessary. Small changes can yield significant improvements.

Radial Ball Bearings Selection and Maintenance Insights

This chart illustrates the expected lifespan of various types of radial ball bearings. Selecting the right bearing and adhering to proper maintenance can significantly extend its life, influencing machinery efficiency.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us