How to Choose the Right Angular Bearing for Optimal Machinery Performance

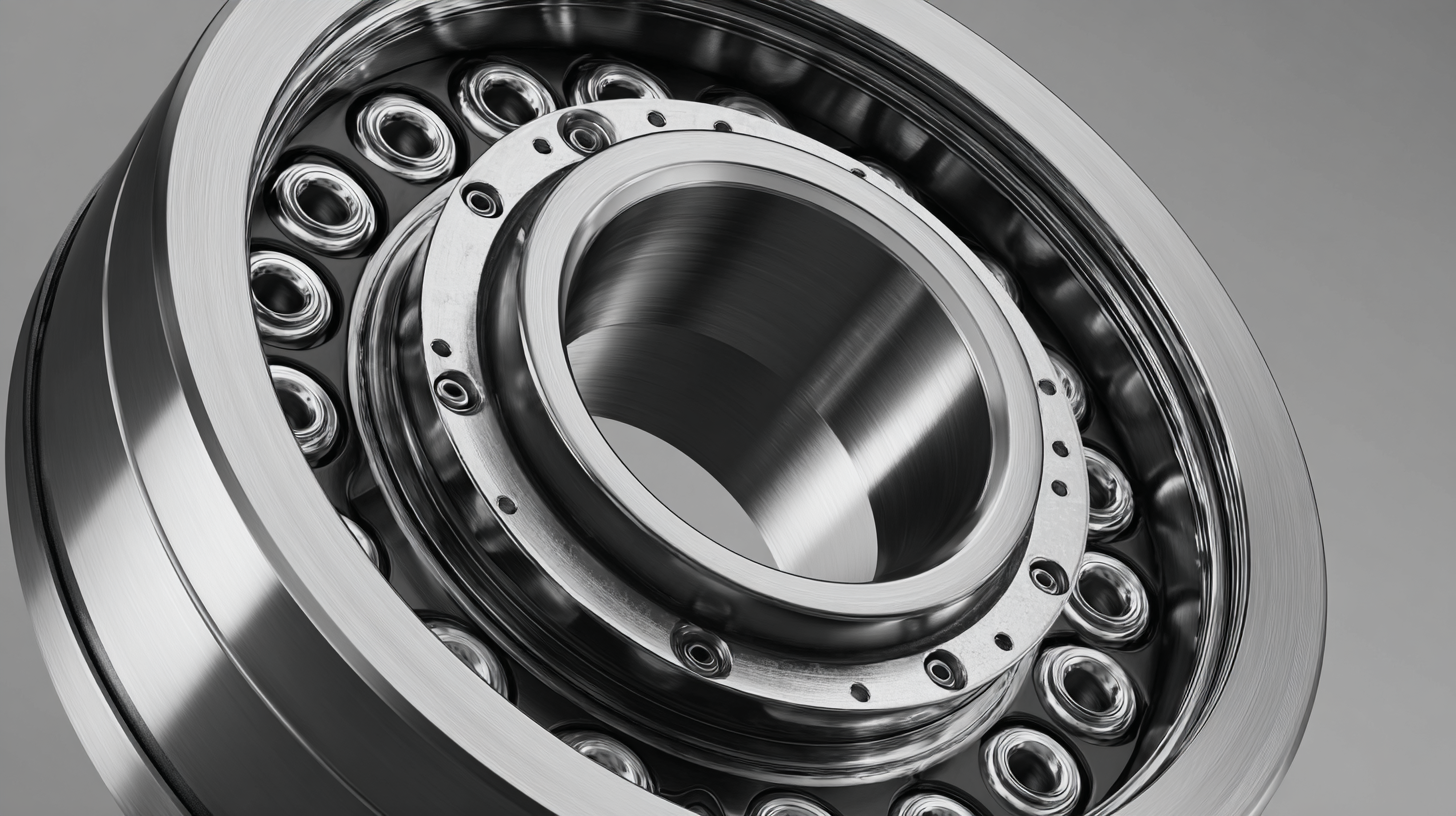

In the realm of precision engineering, the choice of components can significantly impact the overall performance of machinery. Among various types of bearings, angular bearings stand out due to their ability to accommodate axial and radial loads simultaneously, making them indispensable in high-precision applications. According to the International Bearing Association, the global bearing market is projected to reach $100 billion by 2025, driven by the increasing demand for efficiency in manufacturing processes. With the right angular bearing, industries can enhance machine reliability, reduce downtime, and improve operational efficiency. However, selecting the appropriate angular bearing necessitates a thorough understanding of its specifications, load capacities, and application requirements. This blog aims to guide you through the essential considerations for choosing the right angular bearing to optimize machinery performance, ensuring that your equipment operates at its peak potential.

In the realm of precision engineering, the choice of components can significantly impact the overall performance of machinery. Among various types of bearings, angular bearings stand out due to their ability to accommodate axial and radial loads simultaneously, making them indispensable in high-precision applications. According to the International Bearing Association, the global bearing market is projected to reach $100 billion by 2025, driven by the increasing demand for efficiency in manufacturing processes. With the right angular bearing, industries can enhance machine reliability, reduce downtime, and improve operational efficiency. However, selecting the appropriate angular bearing necessitates a thorough understanding of its specifications, load capacities, and application requirements. This blog aims to guide you through the essential considerations for choosing the right angular bearing to optimize machinery performance, ensuring that your equipment operates at its peak potential.

Key Factors to Consider When Selecting Angular Bearings for Machinery

When selecting angular bearings for optimal machinery performance, several key factors must be taken into account. Firstly, the load conditions are critical; angular bearings are designed to carry both axial and radial loads. Understanding the specific load types your machinery will encounter is essential. In high-speed applications, the bearing's material and lubrication will also play a pivotal role in reducing friction and wear, thus enhancing longevity and efficiency.

Another important consideration is the bearing's precision rating, which influences the accuracy of the machinery it supports. Higher precision bearings are necessary for applications that require tight tolerances, such as in medical devices or aerospace components. Additionally, the operating environment cannot be overlooked; factors like temperature extremes, humidity, and exposure to contaminants can severely impact bearing performance. Selecting the right angular bearing involves a detailed analysis of these factors to ensure your machinery operates at peak performance while minimizing the risk of failure.

Understanding Different Types of Angular Bearings and Their Applications

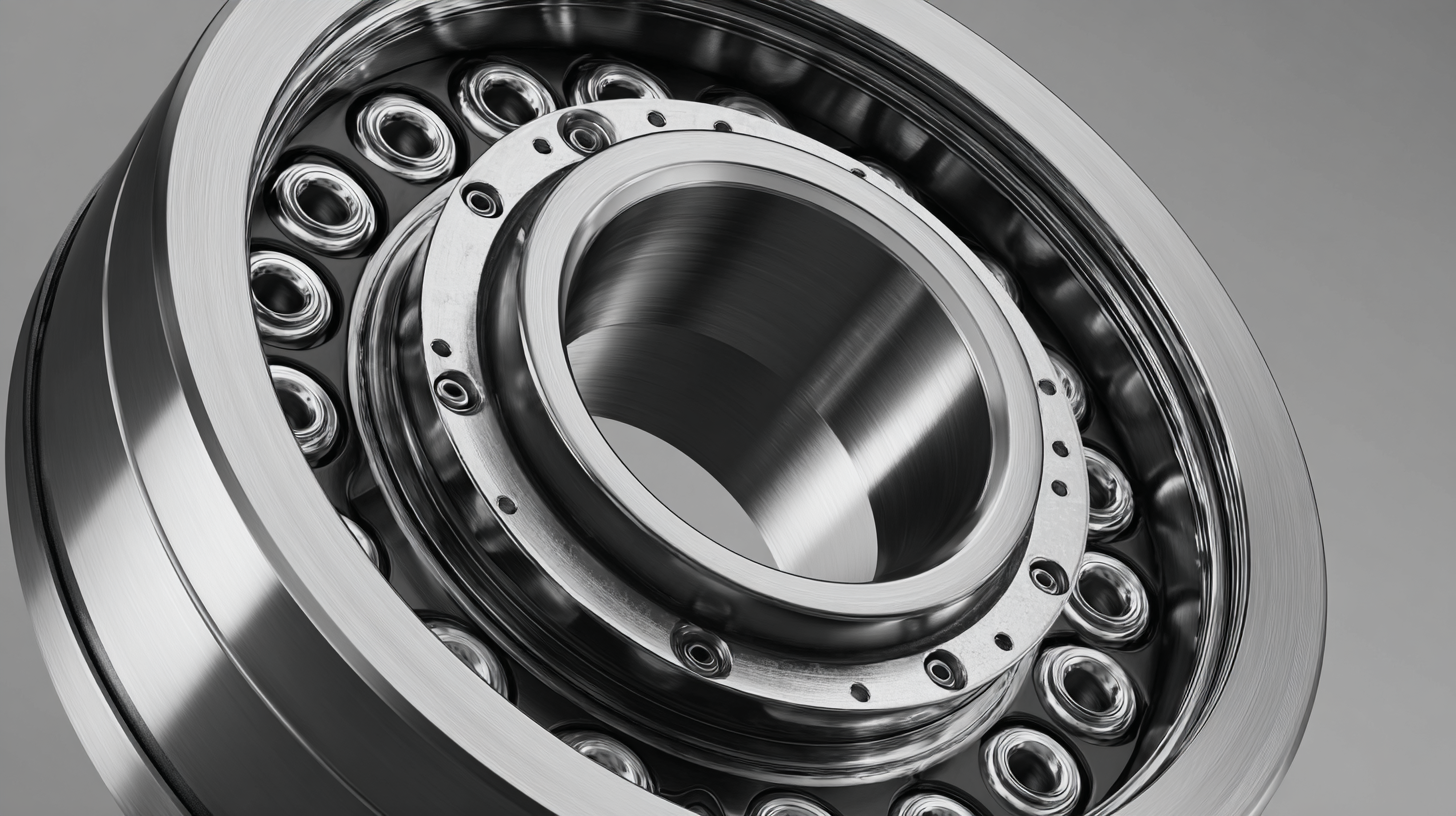

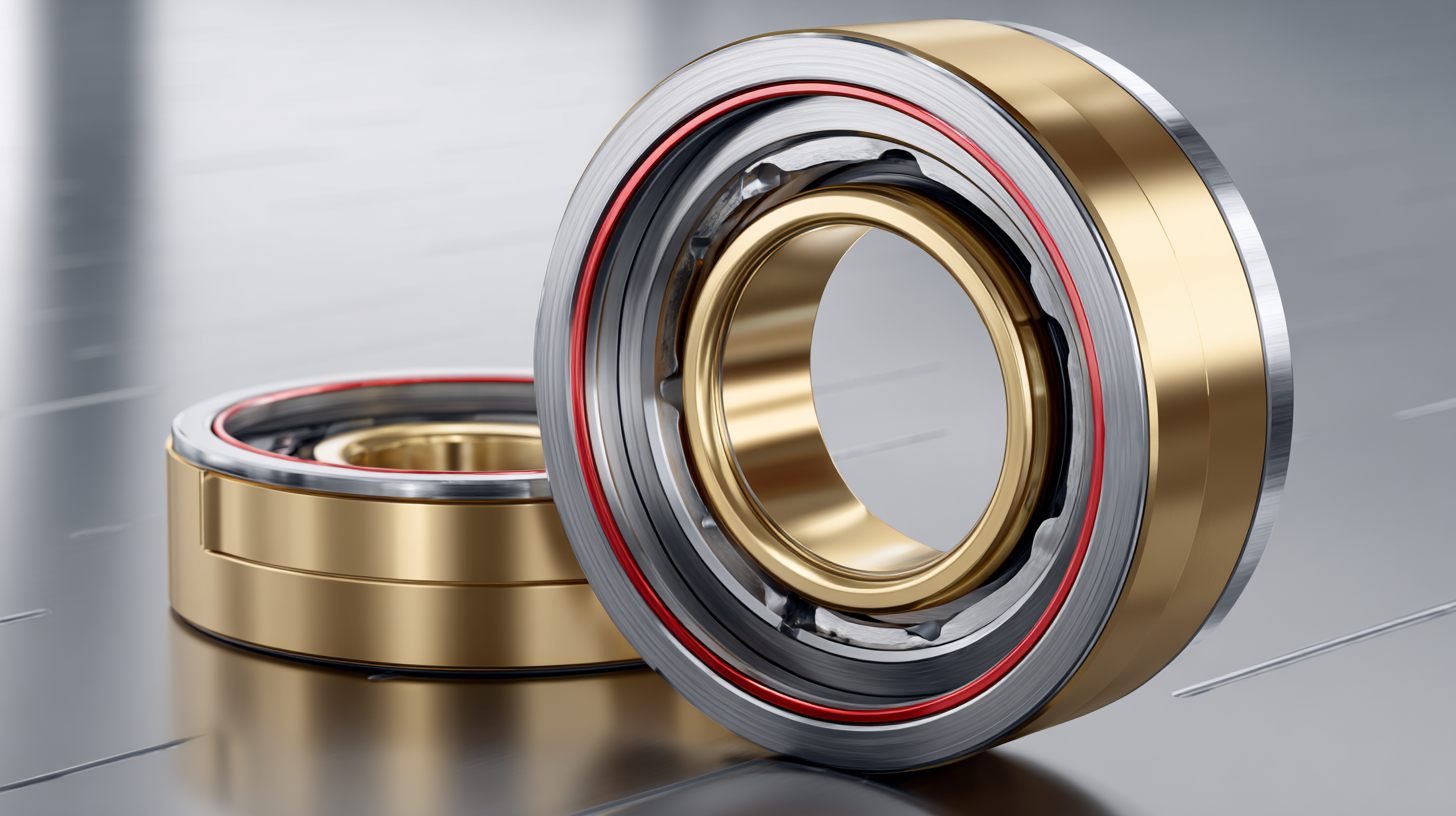

When selecting angular bearings, understanding their types and applications is crucial for optimal machinery performance.

Angular contact ball bearings, renowned for their ability to support both axial and radial loads, are essential in industries where precision and reliability are paramount.

According to market reports, the global bearings market size was valued at approximately USD 46.82 billion in 2024 and is projected to reach USD 97.10 billion by 2032, highlighting the growing importance of efficient bearing technologies.

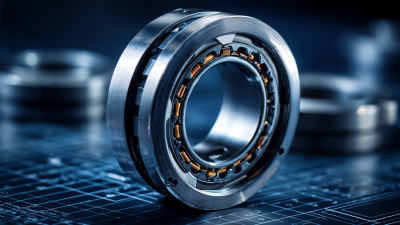

Tips for selecting the right angular bearing include considering the load type – whether axial or radial – and the operational speed of the machinery.

For example, in high-speed applications, deep groove ball bearings may offer better performance, while angular contact ball bearings are preferred in applications requiring direction load support.

Additionally, the trend toward energy-efficient bearings emphasizes the need to reduce friction, which can ultimately enhance machinery longevity and performance.

Another critical aspect is the monitoring of bearing condition. Implementing a vibration analysis setup can significantly improve reliability, especially during gearbox refurbishing.

A comprehensive understanding of different bearing types and their associated technologies will empower manufacturers to make informed decisions that enhance machinery efficiency and performance.

The Role of Load Capacity and Speed in Angular Bearing Selection

When selecting an angular bearing, understanding the balance between load capacity and speed is crucial for optimal machinery performance. Load capacity refers to the maximum load a bearing can withstand, while speed indicates the rotational velocity at which the bearing operates effectively. Choosing a bearing that meets the specific demands of your application can significantly enhance performance and longevity.

Tips for selection: First, assess the operating conditions of your machinery. If high loads are anticipated, opt for bearings with a higher dynamic load rating. Conversely, if your application requires high-speed operation, consider bearings specifically designed to minimize friction and heat generation. It is essential to match the bearing's specifications to the expected load and speed to prevent premature failure.

Additionally, regular maintenance and monitoring are key to ensuring that the selected angular bearing performs at its best. Implement a routine inspection schedule to identify any signs of wear or overheating. Keeping an eye on these factors will help extend the lifespan of the bearing and promote the efficiency of your machinery.

Maintenance Tips for Ensuring Longevity of Angular Bearings

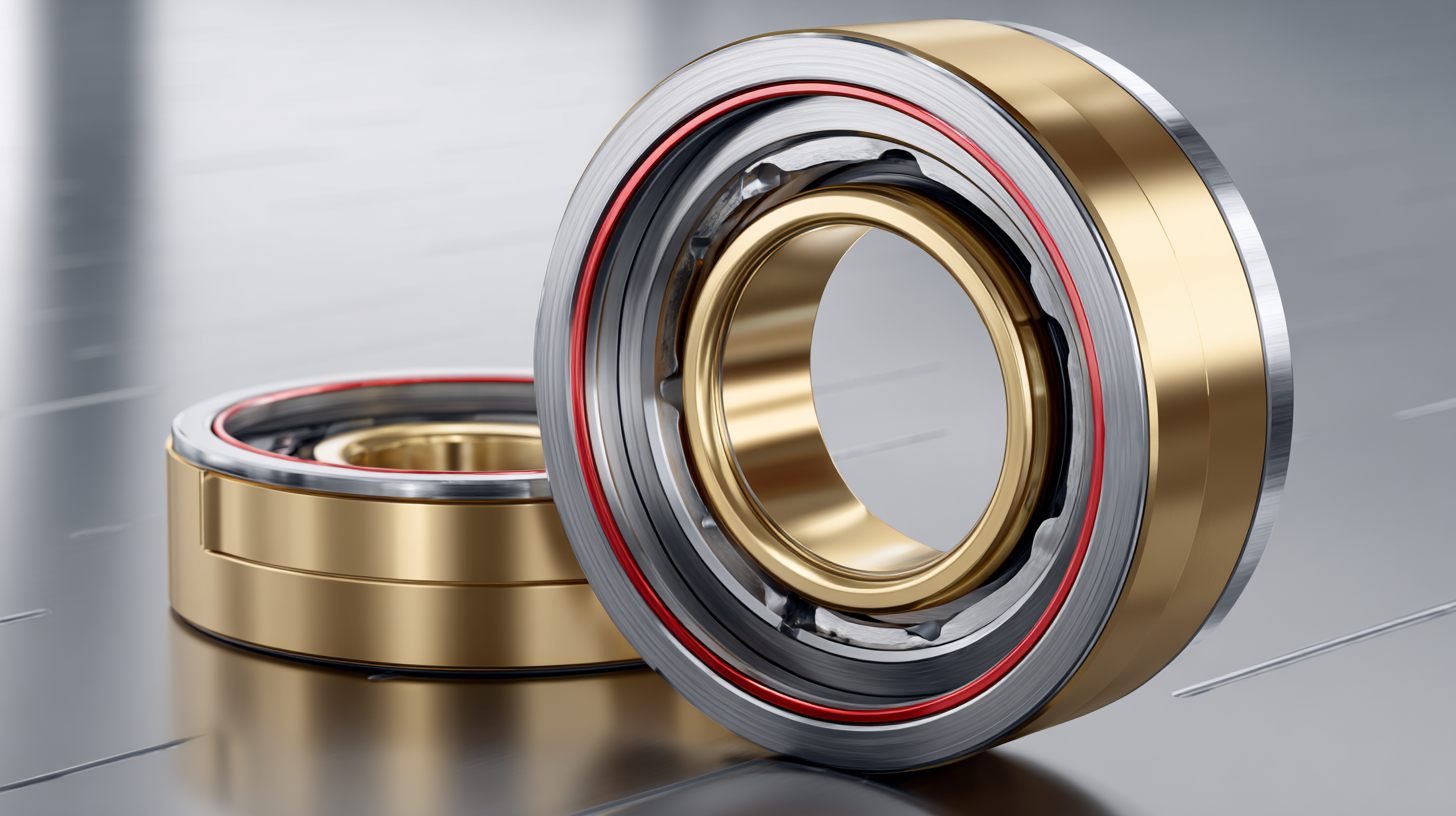

When it comes to maintaining angular bearings, a proactive approach can significantly enhance their longevity and performance. According to a recent report by the International Journal of Advanced Manufacturing Technology, proper lubrication can extend the service life of angular bearings by up to 50%. Regularly monitoring and maintaining the lubricant level not only reduces friction but also prevents overheating, which is a common issue that can lead to premature failure. Utilizing high-quality lubricants specifically designed for angular bearings can further improve their operational efficiency.

Another critical aspect of maintenance is regular inspection. The American Society of Mechanical Engineers (ASME) emphasizes the importance of visual checks for signs of wear, corrosion, or contamination. Implementing a routine inspection schedule can help identify potential problems early, thus minimizing downtime and repair costs. Furthermore, employing vibration analysis techniques can provide valuable insights into the condition of bearings, allowing for predictive maintenance strategies that can increase reliability and decrease unexpected failures. By following these maintenance tips, industries can maximize the performance and lifespan of their angular bearings.

Common Mistakes to Avoid When Choosing Angular Bearings for Your Equipment

When selecting angular bearings for your machinery, it's easy to make common mistakes that could compromise performance. One prevalent error is choosing the wrong bearing size. Bearings that are either too large or too small can lead to misalignment, increased friction, and ultimately premature failure. Ensure you measure your machinery's specifications accurately before making a selection.

Another mistake to avoid is overlooking the load ratings. Each bearing has specific load capacities, and using a bearing that cannot withstand the operational loads will stress the equipment. Always check the dynamic and static load ratings to ensure they match your application's requirements.

Lastly, don't neglect the quality of the bearings. Cutting corners by opting for cheaper, lower-quality bearings might save money upfront, but this could result in higher costs due to maintenance and replacement over time. Invest in reputable brands that provide reliable performance. By steering clear of these pitfalls, you can enhance machinery uptime and efficiency significantly.

Optimal Angular Bearing Selection for Machinery Performance

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

In the realm of precision engineering, the choice of components can significantly impact the overall performance of machinery. Among various types of bearings, angular bearings stand out due to their ability to accommodate axial and radial loads simultaneously, making them indispensable in high-precision applications. According to the International Bearing Association, the global bearing market is projected to reach $100 billion by 2025, driven by the increasing demand for efficiency in manufacturing processes. With the right angular bearing, industries can enhance machine reliability, reduce downtime, and improve operational efficiency. However, selecting the appropriate angular bearing necessitates a thorough understanding of its specifications, load capacities, and application requirements. This blog aims to guide you through the essential considerations for choosing the right angular bearing to optimize machinery performance, ensuring that your equipment operates at its peak potential.

In the realm of precision engineering, the choice of components can significantly impact the overall performance of machinery. Among various types of bearings, angular bearings stand out due to their ability to accommodate axial and radial loads simultaneously, making them indispensable in high-precision applications. According to the International Bearing Association, the global bearing market is projected to reach $100 billion by 2025, driven by the increasing demand for efficiency in manufacturing processes. With the right angular bearing, industries can enhance machine reliability, reduce downtime, and improve operational efficiency. However, selecting the appropriate angular bearing necessitates a thorough understanding of its specifications, load capacities, and application requirements. This blog aims to guide you through the essential considerations for choosing the right angular bearing to optimize machinery performance, ensuring that your equipment operates at its peak potential.