How to Choose the Right Industrial Turntable Bearing?

Choosing the right Industrial Turntable Bearing is essential for operational efficiency. With a global market estimated to reach 2.5 billion USD by 2025, these components are crucial in various applications. In heavy machinery, a well-selected bearing can extend equipment lifespan and reduce maintenance costs.

However, many industries still overlook this important decision. Reports highlight that a staggering 30% of downtime in manufacturing can be attributed to bearing failures. This emphasizes the need for careful evaluation. Selecting the right Industrial Turntable Bearing involves more than just considering size and load capacities.

It's vital to consider environmental factors and load variations. A mismatch can lead to frequent breakdowns, and unexpected costs. Companies must reflect on their choices. Quality, material, and design all play significant roles. It's a complex process, but the right bearing ultimately ensures reliability and peak performance.

Factors to Consider When Selecting Industrial Turntable Bearings

When selecting industrial turntable bearings, multiple factors come into play.

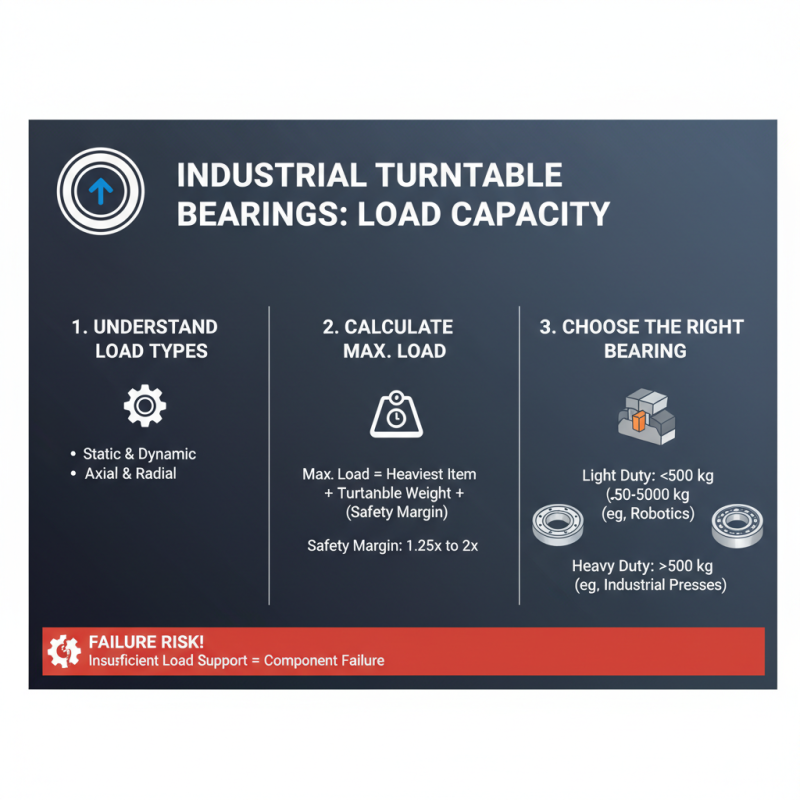

Load capacity is critical.

Consider the maximum weight the bearing must support. A bearing should comfortably handle the load. Insufficient capacity can lead to quick failures. Size matters too. Ensure the dimensions fit your equipment precisely. A mismatch can cause operational issues.

Environmental conditions also impact your choice. If the bearing will face dust or moisture, opt for sealed options. This can prolong its lifespan. Lubrication is another detail not to overlook. Some bearings require regular maintenance, while others are designed to be low-maintenance. Determine what fits your operational needs.

Durability and stability are crucial. Analyze the material of the bearing. Steel is common, but alternatives can offer unique benefits. Don't forget about compatibility with existing machinery. A great bearing can underperform if it doesn't match well with other components. Each detail matters in achieving optimal performance in the long run.

Types of Industrial Turntable Bearings and Their Applications

When selecting industrial turntable bearings, understanding the types is essential. There are several common types:

slewing rings,

ball bearings, and

roller bearings.

Each type serves different applications and environments.

Slewing rings are ideal for heavy loads and slow rotational speeds. They are widely used in cranes and heavy machinery.

Ball bearings suit applications that need high-speed rotation. They work well in smaller, less demanding tasks.

Roller bearings provide excellent load-carrying capacity. They're beneficial for equipment that experiences shock and vibration.

This type is commonly found in construction and agricultural machinery. Assessing your specific needs and environment can lead to better performance.

Tips:

Always consider load requirements. A bearing that can’t handle the load will wear quickly.

Check the environment. Dust and moisture can affect performance.

Regular maintenance is crucial. Even the best bearings will fail without proper care.

Be mindful that not all bearings fit all applications. It’s crucial to choose wisely.

Load Capacity and Performance Ratings of Turntable Bearings

When selecting an industrial turntable bearing, understanding load capacity is crucial. Each bearing type supports different weight ranges. Consider the maximum load you plan to impose. You'll want a bearing that can handle more than your heaviest load. A margin of safety is often wise. High loads without proper support can lead to failures.

Performance ratings add another layer to your decision-making. These ratings reflect how well a bearing operates under specific conditions. Look for factors like speed, temperature, and environment. For instance, some bearings perform poorly in extreme temperatures. Assessing these factors ensures optimal performance. Yet, not all scenarios are straightforward.

Sometimes, bearings that seem perfect may not suit your application. Misalignment or inappropriate mounting can cause wear and tear. It’s essential to reflect on past experiences. Learning from issues can guide future choices. Each application is unique. A deep understanding of your needs will lead to better decisions.

Installation and Maintenance Tips for Turntable Bearings

When it comes to industrial turntable bearings, proper installation and maintenance are crucial. A well-installed bearing ensures smooth operation and extends its lifespan. Start by checking the surface where the bearing will be mounted. It should be clean, flat, and free from debris. Use a level to ensure everything is aligned correctly. Misalignment can lead to premature wear and failure.

During installation, apply the recommended lubricant evenly. Don't overdo it; excess grease can attract dust. Regular inspections are vital for maintaining turntable bearings. Look for signs of wear, such as unusual noises or a rough feel when turning. These can indicate issues that might need addressing.

Remember these tips: always follow the manufacturer’s guidelines, and keep a maintenance log. Documenting any changes in performance will help identify problems early. Maintenance is an ongoing process; neglect can lead to costly downtime. Staying proactive is essential.

Common Mistakes to Avoid When Choosing Turntable Bearings

Choosing the right industrial turntable bearing is crucial. Many overlook significant factors, leading to costly mistakes. One common mistake is underestimating load capacity. Reports indicate that a bearing rated for lower loads could fail quickly, causing downtime. It's essential to assess your operational needs thoroughly.

Another frequent error is neglecting environmental conditions. Bearings exposed to moisture or dust require special seals to function effectively. A study highlights that improper sealing can decrease lifespan by up to 50%. Always consider your specific working conditions.

Tips: Test the bearings under expected loads before full installation. This real-world assessment will help uncover potential weaknesses. Pay attention to compatibility with existing machinery. Misalignment can lead to rapid wear and increased maintenance costs. Lastly, consult industry reports and experts. Their insights can guide your decisions and save money in the long run. Avoiding these pitfalls ensures better performance and longevity for your turntable bearings.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us