How to Choose the Right Agricultural Bearings for Your Needs?

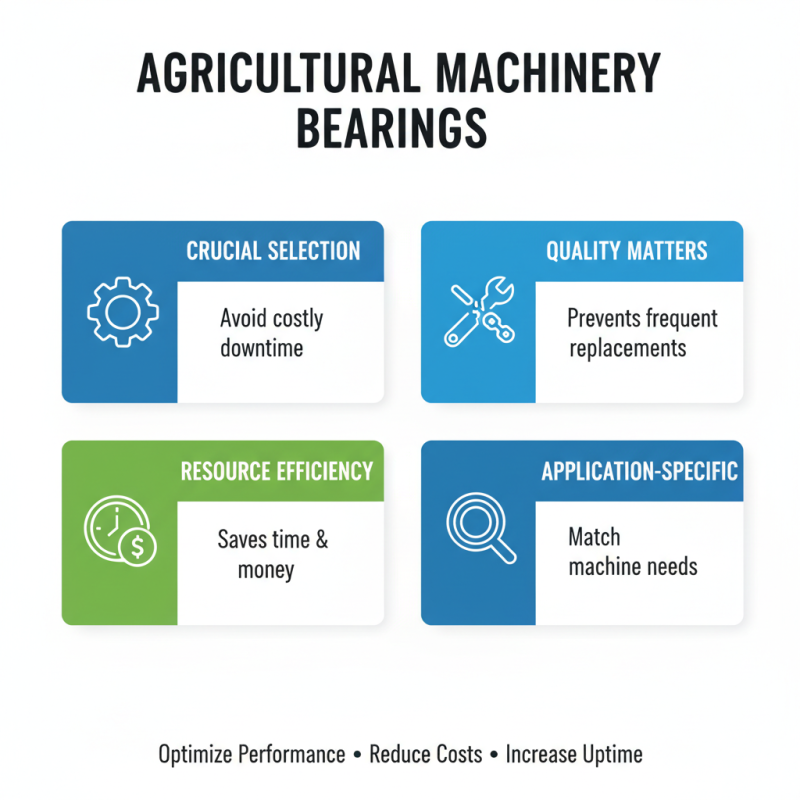

Choosing the right agricultural bearings is crucial for optimal machinery performance. These components play a key role in various farming equipment. Proper selection can improve efficiency and reduce maintenance costs.

Understanding the specific requirements of your equipment is important. Consider the load capacity, speed ratings, and environmental factors. Different agricultural bearings serve distinct purposes. It’s essential to match them with your machinery's needs.

Many farmers overlook the impact of quality bearings. Cheap options may lead to frequent breakdowns and costly repairs. Investing in high-quality agricultural bearings can ultimately save money. Reflect on your choices, and make informed decisions to enhance your operations.

Understanding Different Types of Agricultural Bearings Available

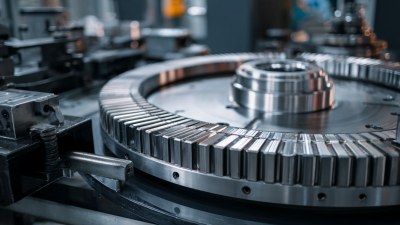

When selecting agricultural bearings, understanding the types available is crucial for optimal performance. There are two main categories: plain bearings and rolling element bearings. Plain bearings are often used in environments with limited lubrication. Rolling element bearings, on the other hand, are preferred for higher speed applications. According to a 2021 market report, rolling element bearings account for over 70% of the agricultural bearing segment due to their efficiency.

Each bearing type comes with specific advantages and limitations. Rolling bearings like ball and roller bearings are known for their load-carrying capabilities. However, they require regular maintenance. Failure to maintain them can lead to premature wear and costly downtime. As reported by industry experts, nearly 28% of agricultural machinery failures are linked to bearing issues. This statistic highlights the need for keen observation and timely intervention.

Material selection also plays a vital role. Some bearings use stainless steel, while others utilize special alloys designed for harsh conditions. Temperature fluctuations and exposure to dust can affect bearing longevity. A comprehensive study noted that inappropriate bearing choice could decrease machinery efficiency by as much as 15%. This reality prompts a closer look at operational environments and requirements when making decisions.

Factors to Consider When Selecting Agricultural Bearings

Choosing the right agricultural bearings is crucial for efficiency in farming operations. When selecting bearings, consider the working environment. Dust, moisture, and extreme temperatures can all impact performance. A bearing might perform well in a clean room but could fail quickly in the field. Make sure to analyze the conditions where the bearing will be used.

Another essential factor is load capacity. Different applications have varying load requirements. Some bearings are designed for heavy loads, while others work best with lighter ones. It is common for farmers to overlook this aspect. Ignoring load details can lead to premature failures or even damage to the equipment. Regular maintenance is vital, but proper bearing selection is the first step to longevity.

Also, think about the installation process. Some bearings are easier to install than others. Complicated setups may lead to errors. Sometimes, it’s beneficial to consult with experts who can provide insights. Remember, making the wrong choice can be costly. Take time to weigh your options carefully and reflect on past experiences. It's easy to rush decisions when under pressure. A thoughtful approach now can save you headaches later.

Factors Influencing Agricultural Bearing Selection

Assessing Load Capacity and Environmental Conditions

When choosing agricultural bearings, assessing load capacity is crucial. Each bearing type has a unique load rating. This rating indicates how much weight it can handle without failure. It's important to match the bearing to your equipment’s needs. Consider the maximum load during operations. Overloading can lead to premature wear and tear.

Environmental conditions also play a major role. Humidity, temperature, and exposure to dirt can affect the bearing's lifespan. For example, extreme heat may cause grease to break down. In contrast, cold conditions can lead to brittleness. Think about where the bearings will be used. Will they be exposed to contaminants? This is essential when selecting seals and materials.

Remember, choosing the right bearing is not always straightforward. Your equipment may require different bearings for varying conditions. Sometimes, it's a trial-and-error process. Keep detailed records of performance. This data can guide future decisions and improve reliability.

Cost-Effective Solutions for Agricultural Bearing Replacement

When it comes to agricultural machinery, choosing the right bearings is crucial. Errors in selection can lead to costly downtimes. Farmers often overlook bearing quality, leading to frequent replacements. This oversight can drain resources and time. Evaluating the application of the bearing is key. Different machines require different specifications.

Cost-effective solutions often depend on understanding your machinery's needs. It’s essential to consider factors like load capacity and operating conditions. A bearing that seems cheap may cost more in the long run if it fails prematurely. Durability is not just a technical specification; it greatly impacts operational efficiency. Small choices can have significant consequences.

Regular inspections of existing bearings can prevent unexpected breakdowns. While replacing them, exploring various suppliers may provide more affordable options. However, not all low-cost products meet necessary standards. Thus, assessing quality remains vital. Finding that balance between cost and reliability can be challenging. Keep an open mind; learning from past decisions is part of the process.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us