Top 10 Tips for Choosing the Right Angular Bearing for Your Project

Choosing the right Angular Bearing is crucial for the success of any engineering project. As the complexity of machinery and applications increases, so does the importance of selecting bearings that offer the right performance traits. Renowned industry expert Dr. Emily Turner emphasizes the significance of this choice, stating, "The perfect Angular Bearing can significantly enhance the efficiency and longevity of mechanical systems, making it vital for engineers to understand their options thoroughly."

Angular bearings are designed to accommodate both axial and radial loads, making them a versatile choice in various applications, from automotive to aerospace. However, with the multitude of options available, selecting the best one might seem daunting for project managers and engineers alike. This guide aims to simplify the decision-making process by outlining the top ten tips for choosing the right Angular Bearing, ensuring that your project can operate smoothly and efficiently.

In the following sections, we will explore key factors such as load capacity, material composition, and friction properties, equipping you with the knowledge needed to make an informed decision. Understanding these aspects will empower you to navigate the intricate world of Angular Bearings with confidence, ultimately leading to enhanced performance in your projects.

Understanding Angular Bearings: Types and Applications

Angular bearings, often referred to as angular contact bearings, play a pivotal role in various mechanical applications due to their ability to support both radial and axial loads. These bearings are distinguished by their design, which allows for a more significant contact angle compared to standard radial bearings. According to a recent report by MarketsandMarkets, the global bearing market is projected to reach over $70 billion by 2025, with angular contact bearings holding a substantial share due to their versatility in serving industries such as automotive, aerospace, and precision machinery.

Types of angular bearings include single-row, double-row, and four-point contact bearings, each tailored for specific operational needs. Single-row bearings are ideal for applications requiring moderate load capacities, while double-row bearings can handle larger loads and higher speeds. The four-point contact style can accommodate both radial and axial loads simultaneously, making it particularly useful in applications like rotary tables and machine tool spindles. A study conducted by Research and Markets indicates that the increasing demand for high-speed machinery and precision equipment is driving the growth of angular contact bearings, highlighting their importance in modern engineering practices.

When selecting an angular bearing, it's essential to consider factors such as load requirements, speed, and environmental conditions. Advanced materials and lubrication technologies have further enhanced the performance and durability of these bearings, allowing them to operate efficiently under extreme conditions. In a competitive market, informed choices based on a thorough understanding of bearing types and their respective applications can significantly impact the overall performance and reliability of a project.

Key Factors to Consider When Choosing Angular Bearings

When selecting the right angular bearing for your project, it's essential to consider several key factors that can significantly affect performance and longevity. First and foremost, the load capacity is crucial. Assess the radial and axial loads the bearing will need to support. Ensuring that the bearing can handle both static and dynamic loads is vital for optimal performance.

Another important factor to consider is the operating environment. Angular bearings can be subjected to contaminants, extreme temperatures, or high speeds. Selecting bearings that are sealed or made of corrosion-resistant materials can enhance their durability and reliability. Additionally, pay attention to the lubrication type; appropriate lubrication can reduce friction and wear, ultimately extending the bearing's lifespan.

When evaluating options, take a moment to prioritize precision and alignment. The angular contact design allows for better load distribution, which is essential for applications requiring high accuracy. Ensuring proper installation and alignment will also play a critical role in maximizing the bearing’s efficiency and reducing unnecessary wear. Remember, making informed choices about the specifications and quality of angular bearings will lead to better performance in your project.

Material Composition and Its Impact on Performance

When selecting an angular bearing for your project, understanding the material composition is essential due to its significant impact on performance. Bearings are typically made from materials like chrome steel, stainless steel, and ceramic. Each material has distinct properties that can influence factors such as load capacity, corrosion resistance, and operating temperature.

According to a report by the American Society of Mechanical Engineers, chrome steel bearings can generally withstand higher loads but may suffer from corrosion if exposed to moisture, making them less suitable for aquatic environments. Conversely, stainless steel bearings offer enhanced resistance to rust, making them ideal for applications where exposure to water or chemicals is a concern.

Furthermore, the use of advanced materials like hybrid ceramics can greatly enhance performance. Combining ceramic balls with steel races can result in bearings that provide lower friction, higher speed capabilities, and reduced wear. According to industry research, hybrid bearings can reduce operating temperatures by approximately 20%, which prolongs the service life and reliability of the application. Thus, when evaluating angular bearings, it is critical to consider not only the specific material properties but also how they align with the operational demands of your project. Selecting the right materials can significantly affect the overall efficiency and durability of the bearing system in service.

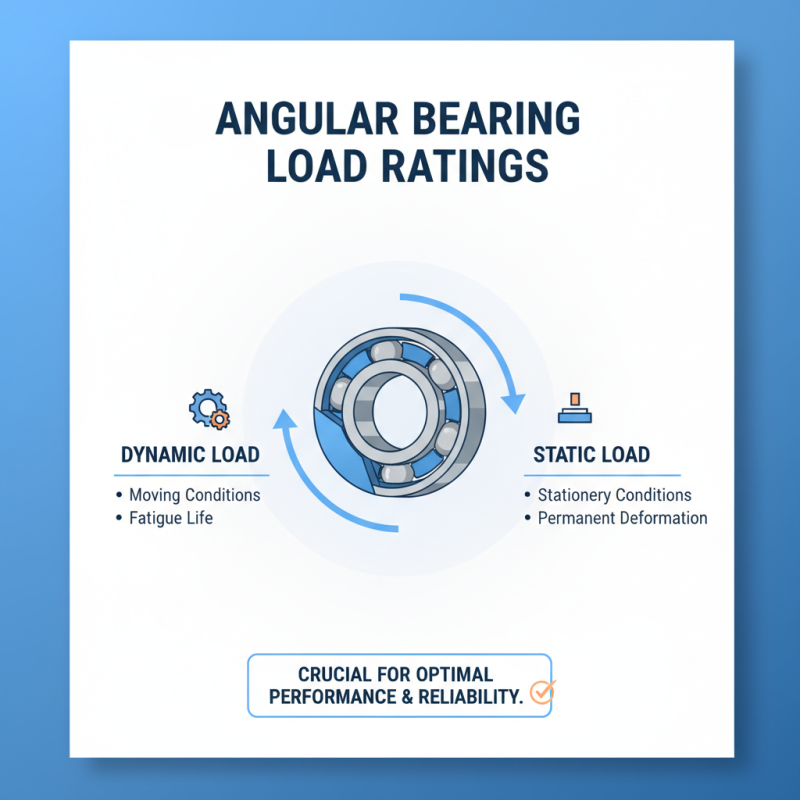

Load Ratings and Their Importance in Bearing Selection

When selecting an angular bearing for a specific application, understanding load ratings is crucial. Load ratings determine the maximum permissible load that a bearing can safely bear under various operating conditions. These ratings are typically expressed as dynamic and static load ratings, which help engineers evaluate how much weight the bearing can handle while in motion and when stationary, respectively. By carefully considering these ratings, one can ensure the bearing performs optimally without the risk of premature failure.

The importance of load ratings extends beyond merely choosing a bearing; they also influence the longevity and reliability of machinery. Inadequate load rating selection can lead to excessive wear, overheating, and ultimately, operational disruption. Therefore, it is essential to match the load ratings of the selected angular bearing with the specific weight and forces expected in the application. Engineers should analyze factors such as load type (radial vs. axial), operating speed, and environmental conditions to make informed decisions, ensuring that the selected bearing not only meets the required load capacities but also aligns with the project’s overall performance goals.

Maintenance Tips for Prolonging Angular Bearing Lifespan

To ensure the longevity of angular bearings, proper maintenance is essential. Regular inspections and cleaning are critical steps in preemptively identifying potential issues. Dust, moisture, and contaminants can significantly diminish the performance of angular bearings. Therefore, it is advisable to clean the bearing surfaces routinely and apply appropriate lubricants that match the operational conditions. Using high-quality lubricants can help reduce friction and wear, which ultimately extends the bearing's lifespan.

Another important aspect of maintaining angular bearings is to monitor their operating conditions. Excessive load and temperature can lead to premature failure. Ensuring that the bearings operate within their specified limits is crucial for maximizing their durability. Implementing a consistent monitoring schedule allows for early detection of anomalies such as unusual noise or vibrations, which could indicate an impending failure. Addressing these concerns promptly can save costs and enhance overall machinery reliability, keeping the bearings functioning optimally for a longer time.

Angular Bearings Lifespan Factors

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us