How to Choose the Right Radial Ball Bearings for Your Project

In the realm of mechanical engineering and manufacturing, the selection of components is critical to the success of any project. Among these components, Radial Ball Bearings play a crucial role in reducing friction and supporting rotary elements within machinery. According to a recent industry report by MarketsandMarkets, the global ball bearings market is projected to reach USD 27.4 billion by 2026, growing at a CAGR of 6.4% from 2021 to 2026. This growth is largely fueled by the increasing demand for efficient and durable bearing solutions across various industries, including automotive, aerospace, and heavy machinery.

Choosing the right Radial Ball Bearings is imperative, as they directly impact the performance and longevity of mechanical systems. Factors such as load capacity, speed ratings, operating temperatures, and environmental conditions must be carefully considered during selection. The ability of bearings to withstand harsh conditions while maintaining operational efficiency can significantly enhance the reliability and performance of the end product. A report by Allied Market Research highlights that the automotive sector alone contributed over 30% of the overall ball bearings market share in 2021, underscoring the importance of precision in bearing selection for various applications.

In conclusion, the right choice of Radial Ball Bearings not only contributes to the functionality and efficiency of machinery but also influences overall project success. Understanding the dynamics of different bearing types and their specific applications is essential for engineers and designers. As industries evolve and demand for high-performance bearings increases, being well-informed about selecting Radial Ball Bearings becomes a pivotal aspect of engineering excellence.

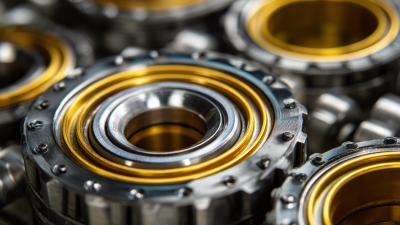

Understanding Radial Ball Bearings: Key Features and Benefits

Radial ball bearings are integral components in various machinery and equipment, offering efficient performance due to their unique design features. One key characteristic of radial ball bearings is their ability to support both radial and axial loads. This versatility makes them suitable for a wide range of applications, from automotive to industrial machinery, ensuring smooth and reliable operation. Their construction typically includes a deep groove design that allows for higher load capacities while maintaining low friction levels, leading to improved efficiency and longevity in operation.

Another significant benefit of radial ball bearings is their relatively low maintenance requirements. Most modern deep groove ball bearings are designed to be pre-lubricated, which minimizes the need for regular servicing and reduces downtime. Additionally, the robust design of these bearings can withstand harsh operating conditions, making them resilient to wear and tear. As a result, they not only contribute to increased performance but also play a crucial role in reducing overall operational costs, further solidifying their position as the most popular type of ball bearing in the market today.

Identifying Your Project Requirements for Optimal Bearing Selection

When selecting the right radial ball bearings for your project, the first step is to identify your specific project requirements. This includes assessing the load conditions, speed, temperature, and environment in which the bearings will operate. According to a report by the International Bearing Association, approximately 40% of bearing failures are attributed to improper selection for load and speed, highlighting the importance of this initial assessment. Additionally, if your application involves high speeds or variable loads, it may be essential to consider bearings with higher precision ratings to ensure longevity and reliability.

Another key factor is the operational environment. Bearings exposed to harsh conditions such as moisture, dust, or extreme temperatures may require special materials or lubrication methods. A study from the Bearing Manufacturers Association indicates that using bearings specifically designed for challenging environments can reduce maintenance costs by up to 25%. Therefore, identifying the precise environmental conditions will help in choosing materials and seals that enhance performance and durability, ultimately ensuring that you select the optimal bearing for your project's unique needs.

Exploring Different Types of Radial Ball Bearings Available in the Market

When choosing the right radial ball bearings for your project, it is essential to explore the various types available in the market, each designed to cater to specific applications. Typically, radial ball bearings can be classified into two main categories: deep groove ball bearings and angular contact ball bearings. According to a report by MarketsandMarkets, the global ball bearing market is expected to reach USD 18.2 billion by 2025, highlighting the growing demand for precision-engineered bearing solutions in industries such as automotive and aerospace.

Deep groove ball bearings are versatile and widely used due to their ability to accommodate both radial and axial loads. They are ideal for electric motors, pumps, and general machinery.

On the other hand, angular contact ball bearings are designed for applications that require higher speeds and greater axial load capacities. They are particularly beneficial in machine tool spindles and gearboxes. A recent industry analysis revealed that the angular contact bearing segment is projected to experience significant growth, driven by advancements in automated machinery and increased production efficiency.

Understanding the specific requirements of your application, including load capacity, speed, and environmental factors, is critical in selecting the appropriate type of radial ball bearing. Industry reports suggest that improper bearing selection can lead to premature failure, increased maintenance costs, and reduced operational efficiency, emphasizing the importance of making an informed choice.

Evaluating Material and Design Options for Enhanced Performance

When selecting radial ball bearings for your project, the material and design choices play a crucial role in determining performance and durability. Common materials for ball bearings include stainless steel, chrome steel, and ceramic. Stainless steel is known for its corrosion resistance, making it suitable for humid or wet environments, while chrome steel offers good hardness and load capacity. For high-speed applications, ceramic bearings can reduce friction and wear significantly, thereby enhancing performance.

**Tips:** When choosing materials, consider the environment in which the bearings will operate. For instance, if you're working in harsh conditions, opt for corrosion-resistant materials like stainless steel or specialized coatings.

The design of radial ball bearings also significantly affects their performance. Features such as the type of cage, clearance, and sealing options can influence how well the bearings function under load. A well-designed cage can provide improved lubrication retention and reduced friction, while effective sealing options can prevent contaminants from entering the bearing.

**Tips:** Always refer to the manufacturer's specifications for the recommended design features suited for your application. Customize the clearance based on thermal expansion and load requirements to ensure longevity and reliability.

How to Choose the Right Radial Ball Bearings for Your Project - Evaluating Material and Design Options for Enhanced Performance

| Material |

Load Capacity (N) |

Speed Rating (rpm) |

Design Type |

Temperature Range (°C) |

| Chrome Steel |

2000 |

5000 |

Single Row |

-20 to 120 |

| Stainless Steel |

1500 |

4000 |

Double Row |

-40 to 150 |

| Ceramic |

3000 |

6000 |

Hybrid |

-50 to 200 |

| Plastic |

800 |

3000 |

Single Row |

-20 to 80 |

Tips for Sourcing Quality Radial Ball Bearings for Your Application

When sourcing quality radial ball bearings for your application, several key factors should be taken into consideration to ensure optimal performance and longevity. First, assess the specific requirements of your project, including load capacity, speed, and environmental conditions. This will help you determine the appropriate bearing type and material. For example, if your application involves high temperatures or corrosive environments, specialty materials such as stainless steel or ceramic may be necessary.

Next, research potential suppliers thoroughly. Look for manufacturers with a strong reputation for quality and reliability. Check for certifications and quality control processes in place; these often indicate a commitment to producing high-grade products. Additionally, consider the supplier's ability to provide technical support and information, which can be invaluable during the selection process. By following these tips, you can ensure that you choose the right radial ball bearings that meet your project's needs and contribute to its overall success.

Radial Ball Bearings Selection Criteria

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us