How to Choose the Right Rotating Bearing for Your Industrial Applications

In the realm of industrial applications, the selection of the appropriate rotating bearing is critical for ensuring optimal performance and longevity of machinery. According to a report by MarketsandMarkets, the global bearing market is projected to reach $131.5 billion by 2025, with rotating bearings playing a vital role in this growth due to their essential function in reducing friction and supporting loads in rotational applications. The right choice of rotating bearing can significantly impact operational efficiency, maintenance costs, and energy consumption, making it paramount for engineers and procurement specialists to understand the various types of rotating bearings available. With advancements in technology and materials, the criteria for selection are evolving, necessitating a comprehensive approach that considers dimensions, load capacity, speed rating, and environmental conditions. Therefore, this guide aims to provide insights into how to effectively choose the right rotating bearing for diverse industrial needs, ensuring an informed decision-making process that aligns with current industry standards and trends.

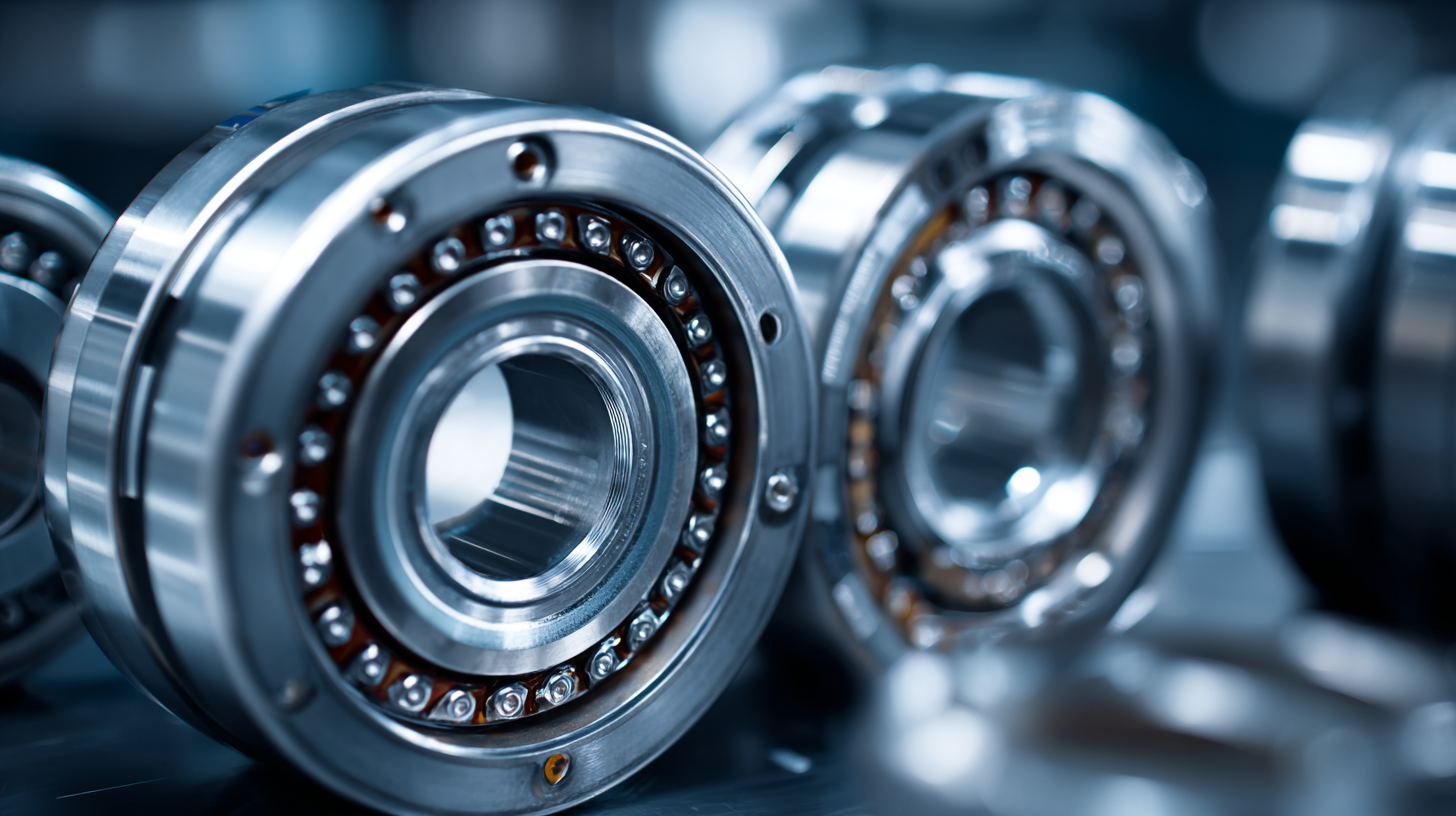

Understanding the Different Types of Rotating Bearings for Industrial Use

When choosing the right rotating bearing for industrial applications, understanding the different types of rotating bearings is crucial.

The primary categories include ball bearings, roller bearings, and plain bearings, each offering unique advantages depending on the application requirements.

Ball bearings are typically used in high-speed applications due to their ability to reduce friction effectively,

while roller bearings are better suited for handling heavy loads.

Plain bearings, on the other hand, provide a simple, robust solution for various environments but may require more maintenance.

The global bearings market continues to expand, reflecting the growing demand for efficient mechanical components across various industries.

As reported, the market size was valued at USD 46.82 billion in 2024, with projections indicating growth to

USD 50.16 billion in 2025 and reaching an estimated USD 97.10 billion by 2030.

This increase underscores the need for businesses to invest in the appropriate rotating bearings tailored to their specific operational needs,

ensuring optimal performance and longevity of machinery. Adopting the right bearing type not only enhances efficiency but also contributes to overall cost savings in industrial operations.

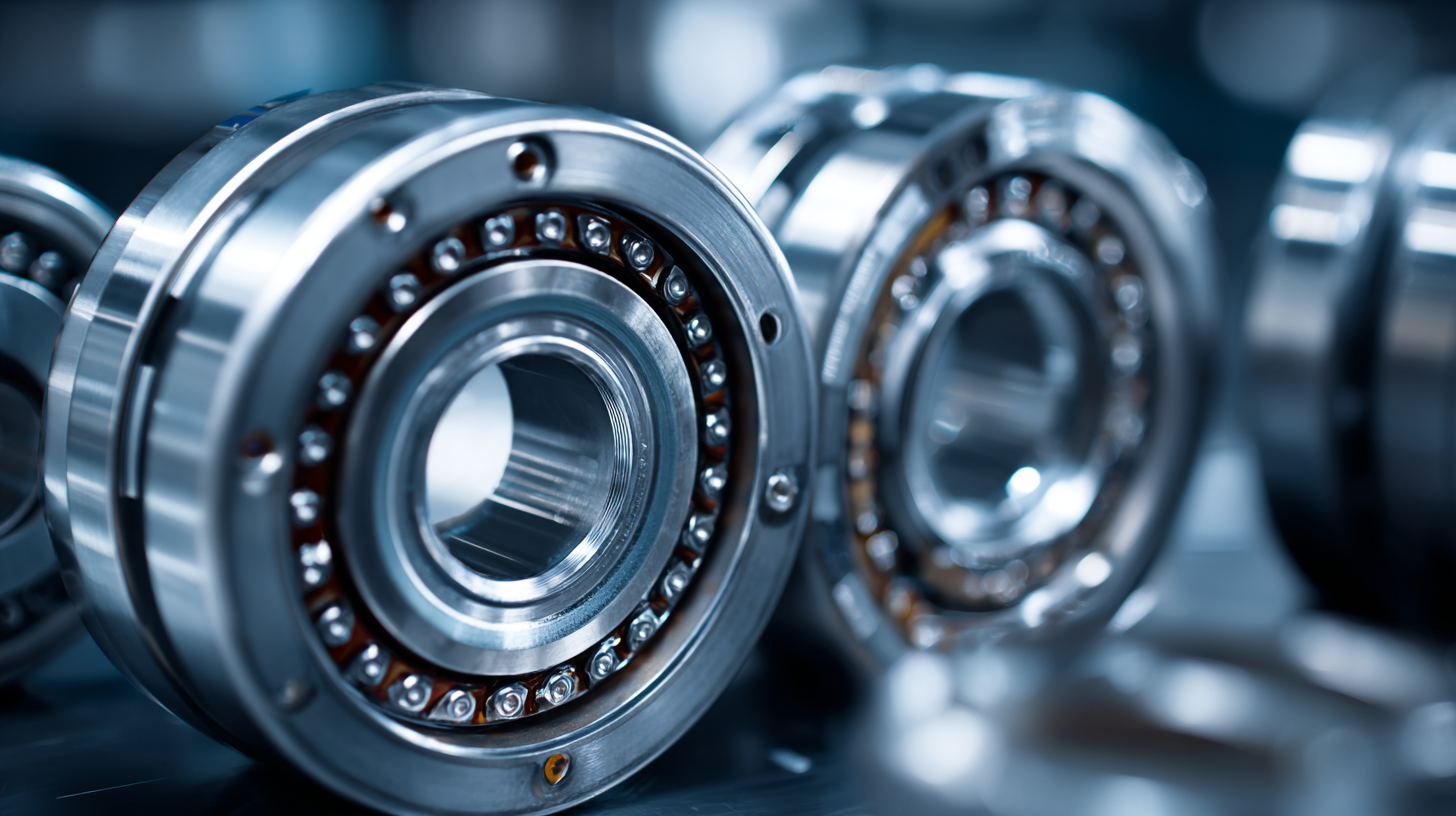

Key Factors to Consider When Selecting a Rotating Bearing

When selecting a rotating bearing for industrial applications, several key factors must be considered to ensure optimal performance and longevity. One of the primary considerations is the load capacity of the bearing. It is essential to determine the type and magnitude of the loads—both radial and axial—that the bearing will encounter during operation. This information allows you to choose a bearing that can withstand these forces without premature failure.

Another critical aspect is the operating environment. Bearings may be subjected to extreme temperatures, humidity, or contamination, which can significantly affect their performance. Selecting bearings with suitable materials and seals is crucial for durability in harsh conditions. Additionally, the speed of operation plays a vital role; high-speed applications often require specialized bearings that can reduce friction and heat generation. Taking these factors into account will help ensure that the selected rotating bearing meets the specific demands of the application, enhancing efficiency and reducing maintenance costs.

Evaluating Load Capacity and Speed Requirements for Bearings

When selecting the right rotating bearing for industrial applications,

evaluating load capacity and

speed requirements is crucial.

According to a report by the International Organization for Standardization (ISO),

bearings must be selected based on the dynamic load rating (C)

and the static load rating (Co).

For instance, a bearing's load capacity should exceed the maximum load

experienced in operating conditions, allowing for a safety margin.

Common industrial applications may require bearings with a dynamic

load rating ranging from 25 kN

to over 300 kN, depending on the

specific application, such as gear machines or conveyor systems.

Speed requirements also play a significant role in bearing selection.

The speed limit of a bearing is primarily

determined by its design, lubrication, and operating conditions.

Research from the American Bearing Manufacturers Association (ABMA)

indicates that high-speed applications often require bearings specifically

designed for minimal friction and enhanced thermal performance.

These bearings can sustain rotational speeds exceeding

100,000 RPM in precision applications.

Therefore, understanding both load capacity and speed is essential to

ensure optimal performance and longevity in industrial settings.

Material Selection for Durability and Performance in Bearings

When selecting materials for rotating bearings in industrial applications, durability and performance are paramount. Recent advancements in materials science have highlighted the importance of using high-performance composites and alloys that can withstand extreme operating conditions. For instance, the development of specialized aircraft bearings designed to endure elevated temperatures and pressures underscores the need for robust material choices. These bearings utilize advanced materials to ensure reliability and longevity, which is crucial in aerospace manufacturing where performance consistency is essential.

Furthermore, the growing implementation of 3D printing technology has revolutionized material selection for bearings. This process allows for the creation of high-performance plain carbon steels with tensile and impact properties comparable to those of ultra-high strength alloy steels. Studies indicate that 3D-printed materials can achieve a strength-to-weight ratio that meets the demanding requirements of various industrial applications, including those in the energy sector where electrolyser stack performance is critical. By leveraging the unique properties of materials available through modern manufacturing techniques, engineers can optimize the performance of rotating bearings, ensuring they meet both durability and efficiency standards.

How to Choose the Right Rotating Bearing for Your Industrial Applications - Material Selection for Durability and Performance in Bearings

| Bearing Type |

Material |

Load Capacity (N) |

Speed Rating (RPM) |

Durability Rating (Hours) |

| Ball Bearing |

Stainless Steel |

5000 |

12000 |

20000 |

| Roller Bearing |

Chrome Steel |

7000 |

10000 |

15000 |

| Tapered Roller Bearing |

Carburized Steel |

8500 |

8000 |

30000 |

| Spherical Bearing |

Bronze |

6000 |

7000 |

25000 |

| Sleeve Bearing |

Plastic |

4000 |

5000 |

10000 |

Maintenance Tips for Prolonging the Life of Rotating Bearings

Maintenance is crucial for prolonging the life of rotating bearings in industrial applications. According to a report from the American Society of Mechanical Engineers (ASME), improper maintenance can lead to a 30-50% decrease in bearing lifespan, resulting in significant downtime and repair costs. To mitigate these risks, regular inspections and timely lubrication are essential. Utilizing high-quality lubricants based on the manufacturer's specifications can substantially enhance performance, reducing friction and wear.

Additionally, maintaining optimal operating temperatures is critical. Research conducted by SKF indicates that for every 10°C increase beyond the recommended operating range, the bearing life can be decreased by half. Effective cooling systems and monitoring technology can help maintain appropriate temperatures, thereby extending bearing life. Furthermore, implementing vibration analysis can pinpoint early signs of failure, allowing for proactive maintenance adjustments. By following these guidelines and staying informed about the latest developments in bearing technology, industries can ensure the reliability and longevity of their rotating bearings.

Rotating Bearings Performance and Maintenance Analysis

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us