A Deep Dive into Angular Bearing Types and Their Unique Advantages

In the world of mechanical engineering and design, Angular Bearings play a crucial role in ensuring the smooth operation and longevity of machinery. This ultimate guide delves into the various types of Angular Bearings, shedding light on their unique advantages and applications across different industries. From their ability to handle combined loads to their versatility in accommodating misalignment, Angular Bearings offer distinct benefits that make them indispensable in modern engineering solutions. Whether you are a seasoned engineer looking to deepen your understanding or a novice seeking foundational knowledge, this comprehensive exploration will equip you with valuable insights into the essential characteristics and functionalities of Angular Bearings. Join us as we navigate through the intricacies of these bearings, highlighting not only their design but also the innovative advancements shaping their future.

Understanding Angular Bearing Alternatives: Key Considerations

When considering angular bearing alternatives, several key factors come into play.

Primarily, load capacity and rotational speed are vital parameters.

According to a report by the International Journal of Engineering Research and Applications,

the selection of the right bearing type can enhance performance efficiency by up to 20%.

This is especially critical in high-performance applications where improper bearing selection could lead to premature failure

and increased maintenance costs.

Tips: Always analyze both dynamic and static load ratings when selecting a bearing type;

these metrics will significantly influence your choice based on the required application.

Another consideration is the operational environment. Bearings may be exposed to moisture, dust, or extreme temperatures,

each necessitating specific materials or designs. Recent studies in the Journal of Manufacturing Science and Engineering

highlight that using corrosion-resistant materials

can extend the lifespan of bearings operating in harsh conditions by nearly 50%.

Tips: Evaluate the environmental conditions of your application beforehand

to determine the best material and sealing options for your bearings.

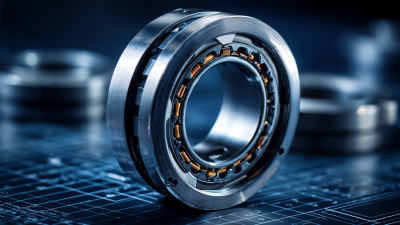

Comparative Analysis of Angular Bearing Types and Their Applications

When analyzing angular bearing types, it’s crucial to understand the distinct applications and advantages offered by each. Angular contact bearings, for instance, are designed to handle both radial and axial loads, making them ideal for high-speed and high-precision machinery. A recent report from the Bearing Industry Association noted that the demand for angular contact bearings is expected to grow by 5.4% annually, driven by advancements in automotive and aerospace sectors, where performance and reliability are critical.

In contrast, the use of double-row angular contact bearings is increasingly preferred in applications requiring higher load capacities. The same report indicates that these bearings can support higher axial loads, which is essential for heavy machinery and equipment like wind turbines and large industrial motors. Additionally, with the growing trend towards miniaturization in electronics, manufacturers are leaning towards miniature angular bearings that offer compact designs without compromising performance. These adaptations highlight the importance of selecting the right type of angular bearing based on specific operational requirements, ultimately improving efficiency and durability in various applications.

A Deep Dive into Angular Bearing Types and Their Unique Advantages

This chart illustrates the comparative advantages of different angular bearing types, showing their applications and benefits across various industries.

Exploring the Advantages of Alternative Angular Bearings in Various Industries

Angular bearings are instrumental in enhancing the efficiency of numerous industrial applications. Their unique design allows them to handle both axial and radial loads, making them versatile solutions for various mechanical systems. For example, in the automotive industry, angular bearings are crucial for the performance of steering columns and wheel hubs, where precise alignment and stability are essential for safety and performance. Their ability to accommodate varying loads and withstand dynamic forces contributes to improved vehicle reliability and longevity.

Additionally, alternative angular bearings, such as those made from advanced materials or featuring hybrid designs, offer distinct advantages in demanding environments. In sectors like aerospace and robotics, the need for lightweight yet durable components is paramount. Bearings made from composite materials or those with ceramic balls can significantly reduce weight while enhancing corrosion resistance and operational longevity. These innovations not only contribute to energy efficiency but also enable machinery to operate smoothly and sustainably in high-performance applications, showcasing the critical role angular bearings play across industries.

Evaluating Performance: How Alternatives Stack Up Against Traditional Bearings

When evaluating the performance of alternatives against traditional angular bearings, it's essential to consider various factors such as load capacity, speed, and friction.

Ceramic bearings, for instance, offer notable advantages, including lower friction coefficients and the ability to withstand higher temperatures. This makes them an ideal choice for high-speed applications where heat generation is a concern.

In contrast, traditional steel bearings may fall short in such environments, leading to increased maintenance and reduced lifespan.

Tips: When choosing between bearing types, assess the specific demands of your application. For projects requiring high precision, hybrid bearings that combine ceramic balls and steel races can provide a balance of performance and durability.

Additionally, consider the environmental conditions in which the bearings will operate; factors such as humidity or exposure to corrosive substances can influence the longevity of standard bearings compared to specialized alternatives.

Another alternative gaining traction is the use of magnetic bearings, which eliminate contact and reduce wear, resulting in virtually frictionless operation.

While they may come with a higher initial cost, their efficiency can lead to significant long-term savings, particularly in energy consumption and maintenance.

Engage with industry experts to determine the best fit for your needs while keeping an eye on the latest advancements in bearing technology.

Future Trends in Angular Bearing Alternatives and Innovations in Design

As the demand for advanced machinery and precision applications continues to rise, the field of angular bearings is witnessing innovative changes. Future trends point towards alternatives such as magnetic bearings and advanced polymer solutions that promise to enhance performance while reducing friction. These emerging technologies offer unique benefits; for instance, magnetic bearings completely eliminate contact, significantly decreasing wear and extending lifespan.

When considering angular bearing alternatives, it's crucial to weigh their long-term advantages against initial costs. Investing in high-quality materials can lead to reduced maintenance and operational downtime, ultimately boosting productivity.

Tips: Always keep an eye on recent innovations in bearing technologies, as they can provide insights into the most effective solutions for your specific applications. It is also beneficial to consult with industry experts who can guide you toward optimal choices based on current trends and your operational needs. Staying informed about advancements in bearing design will equip you to make strategic decisions that align with future engineering requirements.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us