5 Essential Advantages of Choosing Angular Bearings for Your Global Sourcing Needs

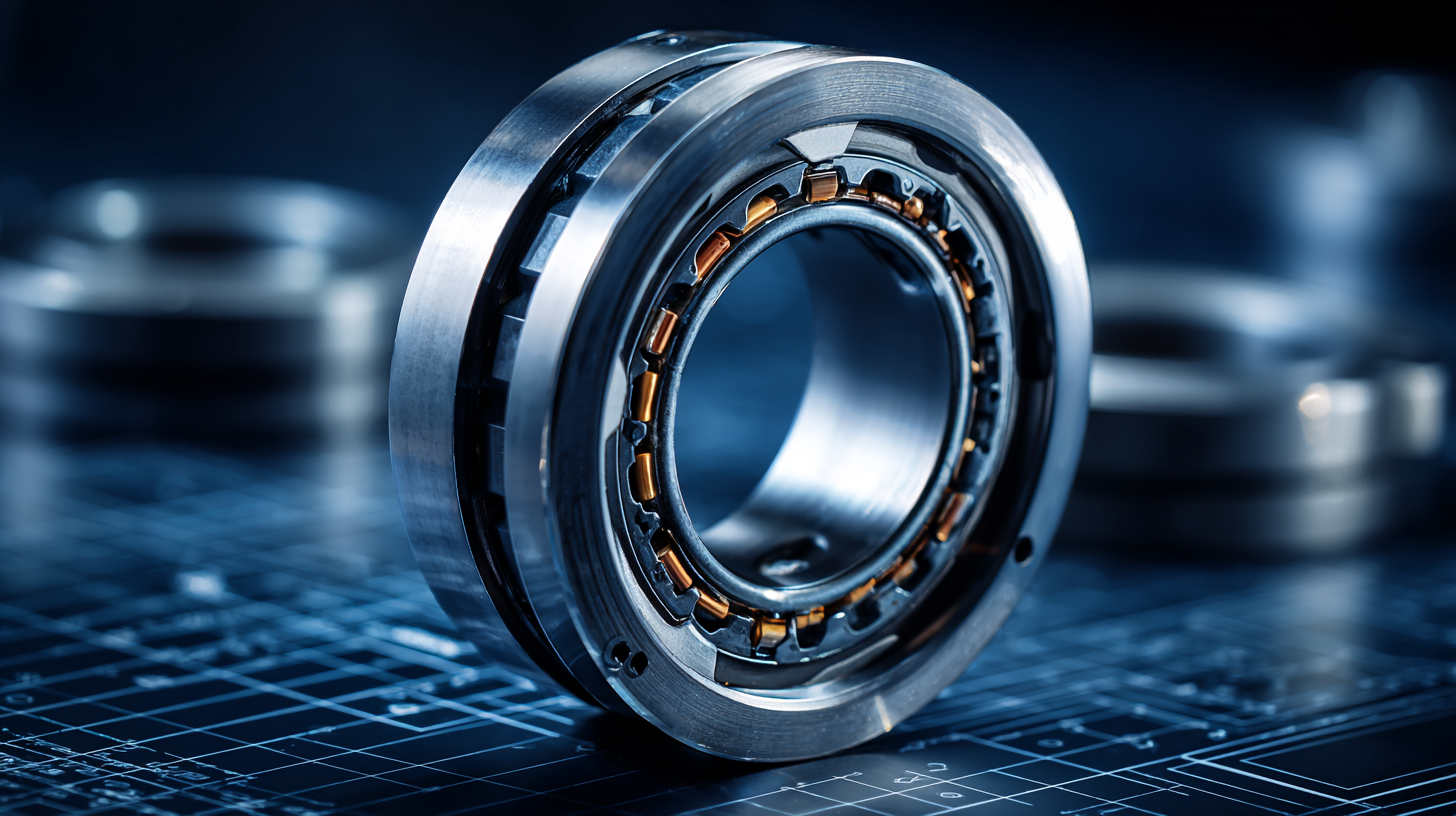

In today’s global sourcing landscape, the selection of the right components is crucial for maintaining competitive advantages, particularly in mechanical engineering applications. Angular bearings, recognized for their capability to support both axial and radial loads simultaneously, play a vital role in enhancing the performance and durability of various machines. According to a recent report by MarketsandMarkets, the global bearing market is projected to reach USD 92.32 billion by 2025, highlighting the growing demand for specialized components like angular bearings. These bearings are increasingly favored in industries ranging from automotive to aerospace due to their superior efficiency, precision, and ability to withstand higher speeds and loads. Understanding the essential advantages of angular bearings can empower businesses to make informed sourcing decisions, ultimately driving innovation and productivity in their operations.

Benefits of Angular Bearings: A Comparative Analysis

Angular bearings have become increasingly popular in various industries due to their unique design that accommodates axial loads in addition to radial loads, offering a significant advantage over traditional bearings. According to a report by the Global Market Insights, the angular contact bearing market is projected to reach approximately $1 billion by 2026, growing at a CAGR of around 5.6%. This growth is primarily attributed to the rising demand for high-speed and high-precision machinery across sectors such as automotive and aerospace, where efficiency is paramount.

One of the critical benefits of angular bearings is their ability to handle combined loads, which is essential in applications where space is limited, and performance is crucial. A study from the American Society of Mechanical Engineers (ASME) highlights that angular bearings can provide up to 30% better load-carrying capacity compared to deep groove ball bearings, making them an ideal choice for heavy machinery and equipment. Furthermore, their preloading capabilities enhance stiffness and reduce vibration, leading to improved operational accuracy and extended machinery lifespan, which are vital factors for global sourcing decisions.

Angular Bearings vs. Traditional Bearings: Key Differences

Angular bearings, particularly angular contact ball bearings, offer distinct advantages over traditional bearings that make them crucial for various applications. One key difference lies in their design, allowing them to handle both radial and axial loads simultaneously. This multifaceted capability enhances their performance in high-speed and precision applications. Innovations in their design, such as the implementation of graphene as a dry lubricant, further boost their efficiency and longevity, reducing maintenance needs and operational costs.

Traditionally designed bearings only manage radial loads, which can lead to limitations in certain applications. In contrast, angular bearings are engineered to bear thrust loads, increasing their applicability across industries such as automotive and aerospace. Additionally, innovations focused on the thermomechanical characteristics of double-row angular contact bearings have demonstrated improved operational stability and heat transfer efficiency, making them suitable for high-performance scenarios, like automotive wheel bearings. As industries evolve and the demands on machinery increase, the versatility and advanced design of angular bearings present a compelling case for their adoption in global sourcing strategies.

Performance and Durability of Angular Bearings in Global Markets

Angular bearings are becoming increasingly essential in the global sourcing landscape due to their performance and durability in various applications. These bearings excel in situations where load and speed requirements are critical, making them a preferred choice for industries ranging from automotive to aerospace. Their unique design allows them to accommodate high axial and radial loads, ensuring that machinery operates efficiently even under heavy stress. This reliability is key in meeting the rigorous demands of global markets, where operational downtime can lead to significant financial losses.

As the global bearings market continues to grow, projected to reach USD 97.10 billion, the impact of angular bearings on this expansion cannot be overstated. With the thin-section bearings market set to grow from USD 3.5 billion to USD 5.2 billion by 2033, the trend indicates a strong preference for components that offer both reduced weight and enhanced performance. The ability of angular bearings to maintain their integrity and operational efficiency over time further cements their position as a crucial element in the machinery of the future, ensuring that businesses can thrive in an increasingly competitive environment.

Performance Comparison of Angular Bearings in Global Markets

Cost-Effectiveness of Angular Bearings for International Sourcing

Angular bearings are increasingly being recognized for their cost-effectiveness in global sourcing. According to a report by MarketsandMarkets, the global bearing market was valued at $70 billion in 2021, with angular bearings holding a significant share due to their versatility and robustness. Their ability to handle both axial and radial loads efficiently means they can reduce the number of components needed in a design, thereby lowering overall production costs. This is particularly advantageous for manufacturers looking to optimize their supply chains.

Furthermore, adopting angular bearings can lead to significant savings in maintenance and replacement. A study by SKF indicated that the right choice of bearings can reduce operational downtime by up to 20%, translating to millions in savings for large-scale operations. This aspect becomes crucial in an international sourcing context where reliability and cost predictability are paramount. By investing in angular bearings, companies can not only achieve immediate cost savings but also enhance the longevity and efficiency of their machinery, making them a strategic choice for any global sourcing strategy.

5 Essential Advantages of Choosing Angular Bearings for Your Global Sourcing Needs - Cost-Effectiveness of Angular Bearings for International Sourcing

| Advantage |

Description |

Cost-Effectiveness |

Applications |

| High Load Capacity |

Angular bearings can support heavy axial and radial loads, making them suitable for various applications. |

Reduced need for support bearings, leading to lower overall costs. |

Industrial machinery, automotive, aerospace. |

| Versatile Design |

Angular bearings come in various configurations, allowing for more adaptable design options. |

Flexible designs can reduce manufacturing costs. |

Robotics, conveyor systems, automotive assemblies. |

| Improved Performance |

They provide smoother and more efficient operation compared to traditional bearings. |

Longer lifespan reduces replacement costs. |

Manufacturing equipment, gaming systems, and precision instruments. |

| Enhanced Rigidity |

Angular bearings offer greater rigidity in applications which require high precision. |

Reduced downtime from misalignment issues lowers total operational cost. |

CNC machines, precision tools, and aerospace applications. |

| Global Availability |

Angular bearings are widely available from multiple suppliers worldwide. |

Competitive pricing from various manufacturers encourages cost savings. |

General manufacturing, automotive production world-wide. |

Applications of Angular Bearings: Why They Stand Out in Industry

Angular bearings are pivotal in various industries due to their unique design and functionality, which allows them to handle both radial and axial loads. This dual capability makes them an ideal choice for applications where precise alignment and high-load support are essential. Industries such as aerospace, automotive, and manufacturing utilize angular bearings for their reliability and efficiency. The growing global bearings market further underscores their importance, with projections indicating significant expansion in various bearing segments, including angular contact bearings.

Angular bearings are pivotal in various industries due to their unique design and functionality, which allows them to handle both radial and axial loads. This dual capability makes them an ideal choice for applications where precise alignment and high-load support are essential. Industries such as aerospace, automotive, and manufacturing utilize angular bearings for their reliability and efficiency. The growing global bearings market further underscores their importance, with projections indicating significant expansion in various bearing segments, including angular contact bearings.

Tips for Choosing Angular Bearings:

When sourcing angular bearings, consider the specific load requirements of your application. Opt for bearings that can handle both the radial and axial loads effectively, ensuring longevity and performance. Additionally, pay attention to the material used in the bearing construction; hybrid options combining steel and ceramics often provide enhanced durability and reduced wear.

Moreover, ensure compatibility with existing machinery. Selecting the correct size and type of angular bearing is crucial for optimal performance. Regular maintenance checks and lubrication can significantly extend the life of these bearings, making them a cost-effective solution for global sourcing needs.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Angular bearings are pivotal in various industries due to their unique design and functionality, which allows them to handle both

Angular bearings are pivotal in various industries due to their unique design and functionality, which allows them to handle both