The Essential Guide to Understanding Radial Ball Bearings for Everyday Applications

In today's fast-paced world, the efficiency of machinery and equipment largely depends on the components that facilitate movement, and one such crucial component is the Radial Ball Bearings. These bearings play a vital role in reducing friction and supporting radial loads, making them essential for the optimal operation of various everyday applications, from household appliances to industrial machinery. Understanding the intricacies of Radial Ball Bearings can empower users to make informed decisions that enhance performance and prolong the lifespan of their devices. This guide aims to demystify the fundamental aspects of these bearings, exploring their design, functionality, and applications, ensuring that both novices and seasoned professionals can benefit from the knowledge shared herein. Whether you're maintaining a personal project or aiming to improve industrial processes, a solid grasp of Radial Ball Bearings is indispensable for achieving precision and reliability in various mechanical systems.

What Are Radial Ball Bearings and How Do They Work?

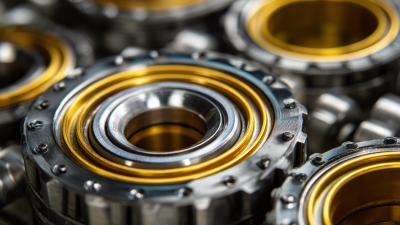

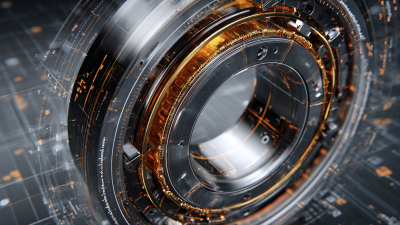

Radial ball bearings are crucial mechanical components widely used in various everyday applications. They consist of an inner ring, an outer ring, ball bearings, and a cage. The primary purpose of radial ball bearings is to reduce friction between moving parts while supporting radial loads. This enables smooth operation in machinery, from household appliances to automotive engines. The design allows for efficient load distribution, which enhances the longevity and performance of the equipment.

Radial ball bearings are crucial mechanical components widely used in various everyday applications. They consist of an inner ring, an outer ring, ball bearings, and a cage. The primary purpose of radial ball bearings is to reduce friction between moving parts while supporting radial loads. This enables smooth operation in machinery, from household appliances to automotive engines. The design allows for efficient load distribution, which enhances the longevity and performance of the equipment.

The recent inauguration of a radial tire manufacturing plant underscores the growing significance of radial technology in modern industry. With an initial investment of over $64 million and a production capacity of nearly one million tires annually, the facility not only contributes to economic development but also emphasizes the advancements in radial designs. The implementation of such technology reflects a commitment to improving quality and efficiency in manufacturing, paralleling the function of radial ball bearings in providing reliability and performance across various applications.

Key Components of Radial Ball Bearings Explained

Radial ball bearings are pivotal components in various everyday applications, providing the necessary support and facilitating smooth rotational motion. The primary parts of a radial ball bearing include the inner race, outer race, balls, and cage. The inner race is the cylindrical part that is mounted onto the shaft, allowing it to rotate freely, while the outer race provides structural support and remains stationary within the housing. The relationship between the inner and outer races is crucial for effective load distribution and minimizing friction.

The balls, typically made from high-quality steel or ceramic materials, sit between the inner and outer races, enabling the bearing to handle radial loads. These balls roll within the races, significantly reducing friction associated with motion. The cage, or retainer, plays an essential role by keeping the balls evenly spaced and preventing them from colliding with one another.

Together, these components ensure that radial ball bearings perform efficiently in various settings, from household appliances to automotive applications, enhancing operational reliability and longevity. Understanding these key components helps users choose the right bearings for their specific needs, ultimately leading to improved performance in their everyday machinery.

Common Applications for Radial Ball Bearings in Daily Life

Radial ball bearings play a critical role in numerous everyday applications, significantly enhancing efficiency and performance in mechanical systems. These versatile components are commonly found in household appliances, such as washing machines and vacuum cleaners, where they facilitate smooth rotation and reduce friction. According to a report by

MarketsandMarkets, the global ball bearing market is projected to reach

USD 68.29 billion by 2026, emphasizing the increasing reliance on these components in various sectors, including consumer goods.

In addition to appliances, radial ball bearings are extensively used in automobiles, supporting rotating elements like wheel hubs and transmission systems. Their ability to handle both radial and axial loads makes them ideal for applications where stability and durability are essential. The automotive sector alone accounted for approximately

40% of the total ball bearing market in 2021, highlighting the crucial role these bearings play in ensuring safety and performance on the road. Furthermore, their presence in electric vehicles is expected to grow, driven by advancements in technology and the demand for enhanced energy efficiency. This underscores the importance of radial ball bearings in shaping our daily lives.

How to Choose the Right Radial Ball Bearing for Your Needs

When it comes to selecting the right radial ball bearing for your needs, understanding the various types and their applications is crucial. The global bearing market is projected to reach a staggering value of $468.2 billion by 2024, with annual growth anticipated to drive its worth to approximately $500.16 billion by 2025, and further surge to about $971 billion by 2032. This rapid growth emphasizes the increasing importance of bearings in diverse industries, from automotive to aerospace, and highlights the need for consumers to choose the appropriate bearings for specific applications.

Choosing the right radial ball bearing involves considering factors such as load capacity, speed rating, and environmental conditions. For example, if your application involves high-speed operations, it's essential to select bearings that can withstand such conditions without excessive wear. Additionally, understanding whether sealed or open bearings are more suited to your application can significantly affect performance and longevity, especially in environments exposed to contaminants. With the right knowledge and data, users can make informed decisions that align with their operational needs and ultimately enhance efficiency and productivity.

The Essential Guide to Understanding Radial Ball Bearings

Maintenance Tips to Extend the Life of Radial Ball Bearings

To ensure the longevity of radial ball bearings in everyday applications, regular maintenance is crucial. One of the simplest yet most effective practices is keeping the bearings clean and well-lubricated. Dirt and debris can accumulate over time, leading to increased friction and wear. Using a proper cleaning solvent and a soft brush can help remove contaminants. Following this, an appropriate lubricant—either grease or oil—should be applied according to the manufacturer's specifications. This minimizes metal-to-metal contact and significantly reduces wear rates.

Another important aspect of maintenance is monitoring bearing performance and performance indicators. Regularly checking for unusual noises, vibrations, or heat emissions can help identify potential issues before they escalate. Additionally, maintaining proper alignment and installation is essential. Misalignment can lead to uneven load distribution and premature failure. By incorporating these maintenance tips, users can effectively extend the operational life of radial ball bearings, ensuring smoother and more reliable performance in various applications.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Radial ball bearings are crucial mechanical components widely used in various everyday applications. They consist of an inner ring, an outer ring, ball bearings, and a cage. The primary purpose of radial ball bearings is to reduce friction between moving parts while supporting radial loads. This enables smooth operation in machinery, from household appliances to automotive engines. The design allows for efficient load distribution, which enhances the longevity and performance of the equipment.

Radial ball bearings are crucial mechanical components widely used in various everyday applications. They consist of an inner ring, an outer ring, ball bearings, and a cage. The primary purpose of radial ball bearings is to reduce friction between moving parts while supporting radial loads. This enables smooth operation in machinery, from household appliances to automotive engines. The design allows for efficient load distribution, which enhances the longevity and performance of the equipment.