10 Essential Tips for Choosing the Right Angular Bearing?

Choosing the right Angular Bearing is crucial in various engineering applications. With the global bearing market expected to reach $92 billion by 2025, the demand for high-quality components has never been greater. Leading industry expert, Dr. Emily Chen, states, "The performance of machinery largely depends on the precision of its bearings." This highlights the significance of making informed choices.

When selecting an Angular Bearing, it's vital to consider load capacities, speed ratings, and environmental conditions. Most users overlook these factors, leading to potential failures. According to a study by the Bearing Industry Association, around 30% of machinery failures are linked to poor bearing choices. This statistic emphasizes the need for careful evaluation.

Reflecting on the selection process can reveal missed opportunities. Many engineers rush decisions without adequate research. Understanding technical specifications is essential to avoid future complications. The right Angular Bearing can enhance efficiency and longevity, ultimately reducing downtime.

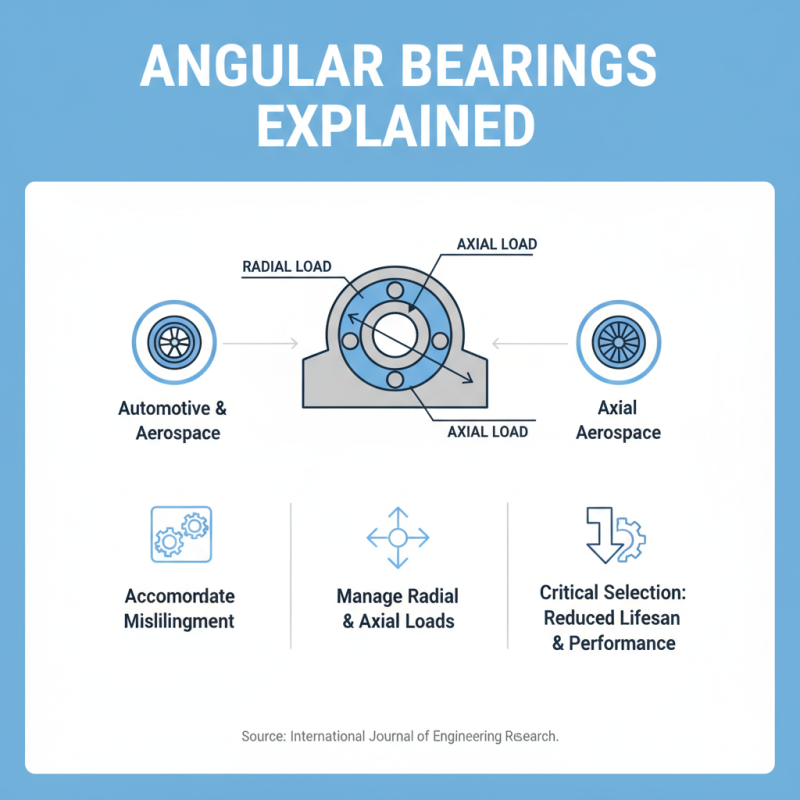

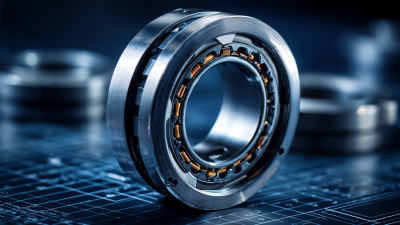

Understanding Angular Bearings: Types and Applications

Understanding angular bearings is essential for various applications, including automotive and aerospace industries. These bearings allow for angular misalignments and can handle both radial and axial loads efficiently. According to the International Journal of Engineering Research, improper selection can lead to a decrease in equipment lifespan and performance.

When choosing angular bearings, consider the type that best fits your application. There are four main types: ball, roller, tapered, and spherical. Each type offers distinct advantages and is suited for specific conditions. For instance, tapered roller bearings are ideal for applications with high axial loads. A recent report from the American Bearing Manufacturers Association indicates that using the wrong bearing type can increase maintenance costs by 30%.

Tip: Assess your load requirements before selecting a bearing. Accurate load estimations prevent premature wear.

Material choice is another crucial factor. Angular bearings can be made from steel, ceramic, or other composite materials. Each material influences the bearing's durability and performance. For example, ceramic bearings can withstand higher temperatures but may be more fragile.

Tip: Analyze the operational environment. Harsh conditions can necessitate specific materials for longevity.

Selecting the right angular bearing is more than just a technical decision. It involves understanding the application, load, and environment. Skipping any step can lead to significant issues down the line.

Key Factors Influencing Angular Bearing Performance and Selection

When selecting an angular bearing, understanding key performance factors is crucial. Load ratings play a significant role. High radial and axial loads demand specific ratings. According to industry data, a bearing’s dynamic load rating impacts its longevity and efficiency greatly. Selecting bearings that match these requirements can enhance performance and reduce failure rates.

Lubrication is another essential factor. It affects heat generation and friction. Poor lubrication can shorten a bearing's lifespan by up to 50%. Different applications may require different types of lubricants. Some environments need sealed bearings to prevent contamination. Choosing the right lubrication method is often overlooked but vital for operational success.

Finally, temperature ranges impact bearing performance. Angular bearings must withstand varying temperature levels. A report from a bearing research journal noted that operating outside recommended temperature limits can decrease bearing life dramatically. Many users fail to consider the environmental conditions before selection. It’s important to reassess your choices based on these critical factors to ensure a suitable and efficient application.

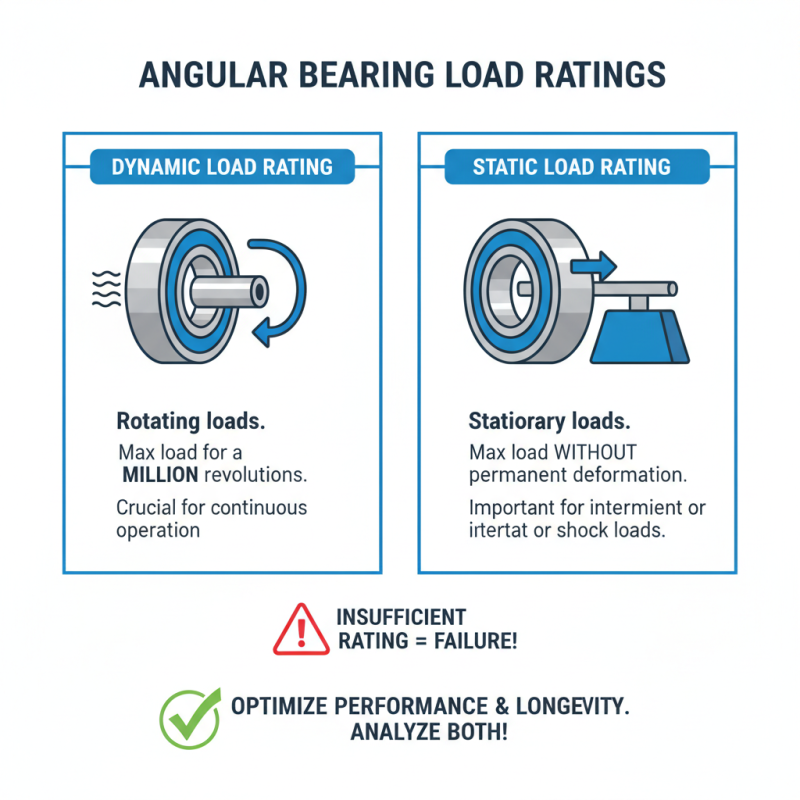

The Importance of Load Ratings and Capacity in Bearing Selection

When selecting an angular bearing, understanding load ratings is crucial. Load ratings indicate how much weight the bearing can handle. If you choose a bearing with an insufficient load rating, it may fail early. This can lead to costly downtime and repairs. Always consider both dynamic and static load ratings in your selection process. A proper analysis helps in optimizing performance and longevity.

In addition to load capacity, consider the application environment. Different scenarios may require different bearing specifications. For instance, a bearing in a high-temperature area will face different challenges than one in a cool environment. Not accounting for these details can result in unexpected failures. It's essential to weigh all factors carefully.

Remember, choosing the right bearing is not a one-size-fits-all scenario. The nuanced requirements of your application can significantly affect performance. In some cases, you might find that the bearing you initially thought was ideal falls short in real-world conditions. This highlights the importance of thorough testing and analysis. Embrace the complexity in bearing selection for the best outcomes.

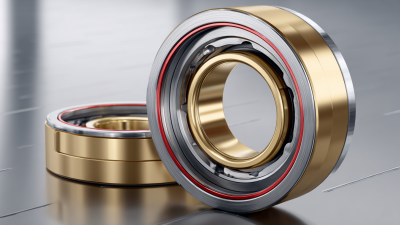

Material Composition: Impact on Durability and Functionality of Bearings

When choosing the right angular bearing, material composition plays a crucial role in both durability and functionality. Typically, common materials include steel, ceramic, and polymers. Steel bearings are strong but can corrode, affecting longevity. In contrast, ceramic bearings provide excellent wear resistance but can be more brittle. A recent industry report highlighted that bearings made from high-grade steel can last up to 50% longer than those made from standard materials under demanding conditions.

Consider the working environment of the bearing. If moisture or extreme temperatures are present, opt for corrosion-resistant options. This choice can significantly increase performance and lifecycle. Tip: Always match the bearing material to the specific application. The right fit minimizes friction and wear, promoting efficiency.

Bearings also undergo varying stress levels. Miscalculation here can lead to premature failure. A study indicated that nearly 30% of bearing failures result from poor material selection. This highlights the need for careful consideration. A practical approach is to review performance data for similar applications. Tip: Consult technical specifications before selection to avoid costly mistakes. Prioritizing material selection ensures longevity and optimal performance in your projects.

Maintenance Practices for Prolonging the Life of Angular Bearings

Maintaining angular bearings is crucial for ensuring their longevity. According to industry reports, proper maintenance can extend their lifespan by up to 50%. Regular inspections for wear and tear are essential. Look for signs like discoloration or unusual noises. These often indicate that it’s time for lubrication or replacement. Ignoring these signs can lead to larger issues down the line.

Lubrication is a key aspect of bearing maintenance. Many experts recommend using high-quality lubricants suited for your specific application. The type and viscosity of the lubricant can significantly affect performance. Keeping a consistent lubrication schedule helps avoid overheating and premature wear. In fact, 30% of bearing failures stem from inadequate lubrication practices. Some operators overlook this aspect, which leads to costly repairs.

Lastly, temperature control plays a critical role. Bearings should operate within their recommended temperature range. Excessive heat can damage the bearing material and affect its functionality. Implementing temperature monitoring systems can provide real-time insights. Yet, many companies fail to invest in these technologies, risking their operational efficiency. Remember, without a solid maintenance plan, even the best bearings can fail prematurely. Assess your current practices and make necessary adjustments.

10 Essential Tips for Choosing the Right Angular Bearing

This chart illustrates the importance of various tips when selecting angular bearings, rated on a scale from 1 to 10 based on user feedback.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us