10 Essential Tips for Choosing the Right Bearing Tools for Your Projects

When embarking on a new project, the selection of appropriate tools can significantly influence the outcome. This is especially true in the realm of mechanical engineering and manufacturing, where "Bearing Tools" play a critical role in ensuring smooth and efficient operation. As industry expert John Carter, a seasoned engineer with over two decades of experience, once stated, "The right Bearing Tools can make or break the success of your project." This highlights the necessity of understanding the various options available and how they fit into your specific requirements.

Choosing the right Bearing Tools involves careful consideration of several factors, including the type of bearing being used, the nature of the project, and the working environment. Understanding these elements not only helps in selecting the most suitable tools but also ensures precision and longevity in the assembly and maintenance of machinery. In this guide, we will explore ten essential tips to help you navigate the selection process effectively, ensuring that your projects are executed flawlessly and efficiently. With the right knowledge and tools at your disposal, you can optimize your workflow and enhance the overall success of your projects.

Understanding Different Types of Bearings and Their Applications

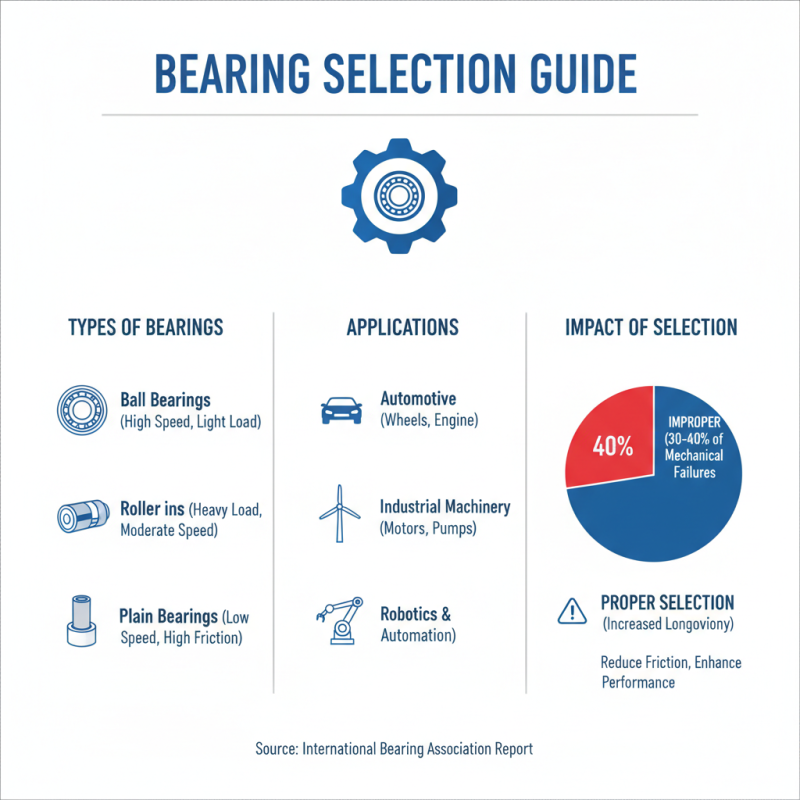

When selecting bearing tools for your projects, understanding the different types of bearings and their applications is crucial. Bearings are essential components that reduce friction between moving parts, and their selection can significantly influence the performance and longevity of machinery. According to a recent report by the International Bearing Association, approximately 30-40% of mechanical failures can be attributed to improper bearing selection. This statistic underscores the need for careful consideration when choosing bearing tools.

There are several common types of bearings, including ball bearings, roller bearings, and plain bearings, each serving specific functions. Ball bearings are ideal for applications requiring high-speed operations and low friction, while roller bearings can support heavier loads due to their larger surface area. Plain bearings, on the other hand, are favored for their simplicity and cost-effectiveness, often used in applications with minimal speed and load demands.

Tip: Prioritize understanding the load conditions and expected speed of your project to determine the most suitable bearing type. Furthermore, consider the operating environment, as factors such as temperature, humidity, and potential exposure to contaminants can affect bearing performance. By analyzing these parameters, you can make an informed decision that enhances the efficiency and reliability of your project.

Essential Factors to Consider When Selecting Bearing Tools

When selecting bearing tools for your project, there are several essential factors to consider that can significantly impact the efficiency and outcome of your work. First and foremost, understanding the specific application and load requirements is crucial. According to the International Society of Automation, the correct selection of bearing tools can enhance operational efficiency by up to 20%. This involves determining the type of load—whether it's radial, axial, or a combination—and assessing the dynamic and static load ratings of the tools you plan to use.

Another critical aspect is the material compatibility of the bearing tools. Studies indicate that the improper selection of material can lead to premature failure, increasing downtime and maintenance costs. For example, a report from the American Bearing Manufacturers Association highlights that nearly 30% of bearing tool failures result from material incompatibility. It is essential to consider factors like temperature, environmental conditions, and chemical exposure to ensure the longevity and performance of the bearings. Overall, carefully evaluating these factors not only contributes to a smoother workflow but also extends the lifespan of your project’s components.

Analyzing Load Ratings and Their Impact on Bearing Performance

When selecting bearing tools for engineering projects, understanding load ratings is crucial for optimal performance. Load ratings, measured in pounds or kilograms, give insight into the maximum forces that bearings can handle before failure. According to industry reports, a bearing's dynamic load rating significantly influences its operational lifespan. For instance, the ISO 281 standard highlights that increasing the load rating by just 10% can potentially double the life of bearings under specific conditions.

Moreover, the impact of load ratings extends beyond just durability; it also affects the efficiency and reliability of machinery. An analysis published in the Journal of Mechanical Science and Technology suggests that improper load application can lead to premature wear and catastrophic failure. A rigorous evaluation of application requirements, such as static and dynamic loads, will aid in selecting the most suitable bearing tools. Research indicates that bearings operating closer to their rated load experience an increased risk of vibration and heat, which can significantly impair performance. Thus, thorough analysis and careful selection based on precise load ratings are paramount in ensuring the longevity and effectiveness of engineering projects.

Material Selection for Bearing Tools: Balancing Strength and Weight

When selecting bearing tools for projects, one of the most critical considerations is material selection, which plays a vital role in balancing strength and weight. According to a recent report by the International Journal of Engineering and Technology, the materials used for bearing tools can significantly affect their performance and longevity. For instance, high-carbon steel is often favored for its exceptional hardness and wear resistance, making it ideal for heavy-duty applications. However, the weight of such materials can pose challenges in terms of handling and operational efficiency, especially in applications requiring precision and maneuverability.

On the other hand, lightweight materials like aluminum and advanced composites are gaining traction in the industry due to their excellent strength-to-weight ratios. A study published in the Journal of Materials Science found that aluminum alloys can provide sufficient strength while substantially reducing the overall weight of bearing tools. This reduction is crucial in sectors such as aerospace and automotive, where every gram counts in enhancing fuel efficiency and overall performance. The key lies in finding the right balance—while strength is essential for durability, minimizing weight can lead to improved efficiency and ease of use across various applications.

Cost Efficiency vs. Quality: Making Informed Purchase Decisions

When it comes to selecting bearing tools for your projects, the balance between cost efficiency and quality becomes critical. According to a recent report by the Machinery and Equipment Manufacturers Association, about 30% of project budget overruns stem from purchasing low-quality tools that require frequent replacements. Investing in high-quality bearing tools initially can significantly reduce long-term expenses, ensuring operational efficiency and reliability in your projects.

Tip: Always evaluate the total cost of ownership (TCO) rather than just the upfront price. This includes considering maintenance costs, tool longevity, and the potential downtime of machinery due to tool failure. A high-quality bearing tool may cost more initially but can ultimately save you money and time.

Moreover, choosing tools based on their intended use is essential. The right tools for heavy-duty applications may not be suitable for lighter tasks. A comprehensive analysis by the Precision Bearing Association indicated that using appropriate tools can enhance productivity by up to 25%. It is vital to align the specifications of your bearing tools with your project demands.

Tip: Conduct thorough research on the materials and technology used in bearing designs to ensure they meet your requirements and provide the performance durability needed for your specific applications. By making informed decisions, you can strike the right balance between cost and quality, driving better results in your projects.

Cost Efficiency vs. Quality in Bearing Tools

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us