7 Essential Tips for Choosing the Right Industrial Turntable Bearing

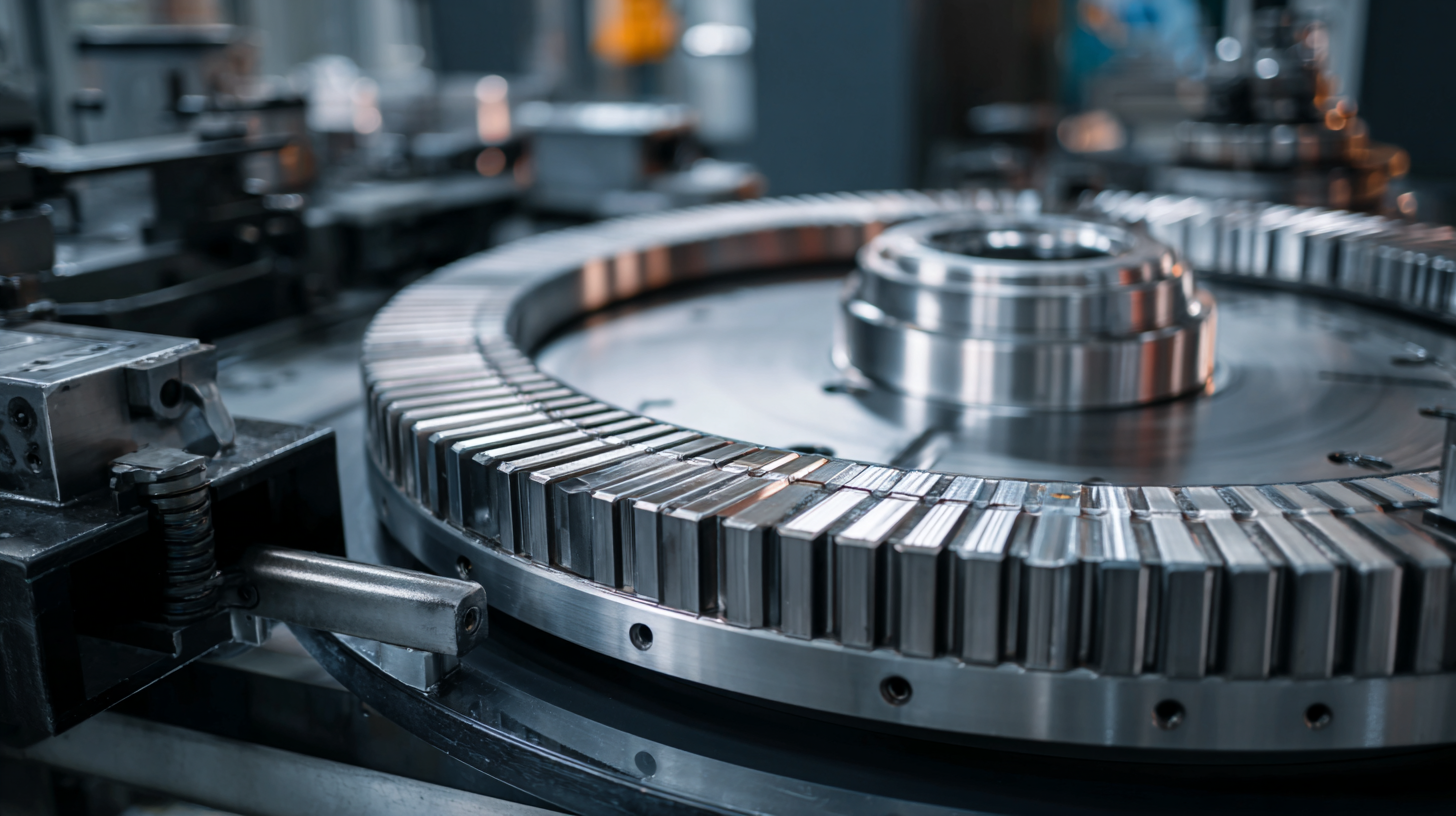

In the realm of industrial machinery, the selection of the right components can significantly impact operational efficiency and longevity. A critical component in this landscape is the Industrial Turntable Bearing, which facilitates smooth and reliable rotation in various applications, from cranes to manufacturing equipment.

According to a recent report by MarketsandMarkets, the global bearing market is projected to reach a staggering $160 billion by 2026, with a noticeable increase in demand for specialized bearings, particularly for industrial uses. The importance of selecting the appropriate turntable bearing cannot be overstated, as it directly influences maintenance costs, performance reliability, and overall productivity.

Understanding the key factors involved in choosing the right industrial turntable bearing is essential for professionals aiming to optimize their operations and reduce downtime.

Understanding the Importance of Industrial Turntable Bearings in Manufacturing

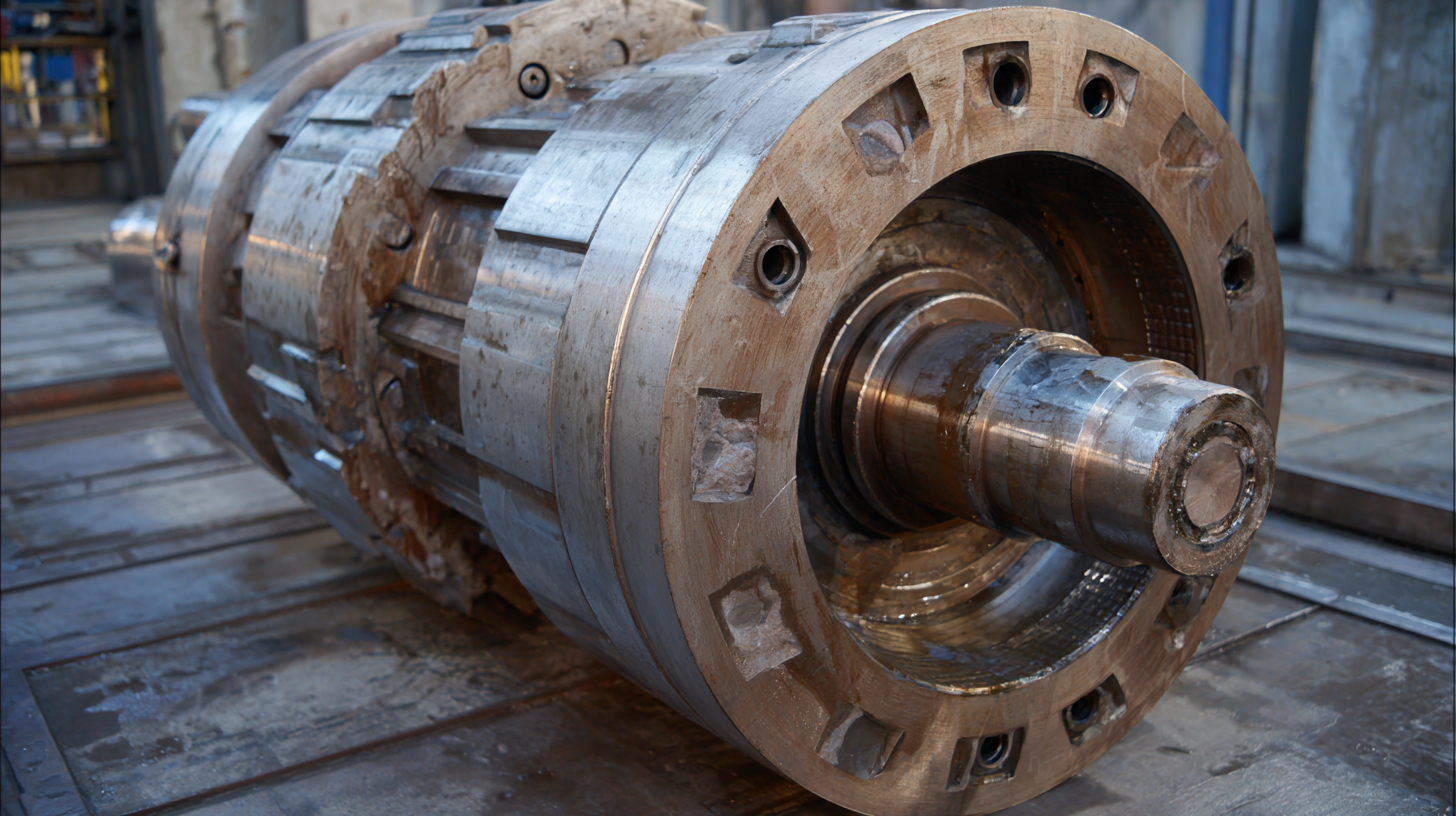

Industrial turntable bearings play a crucial role in the manufacturing sector by ensuring smooth, reliable rotation and movement of heavy loads. These bearings are integral components in various applications, from rotating equipment to conveyor systems. By supporting substantial weights with precision, they enhance operational efficiency and minimize wear and tear on machinery. Understanding their importance is essential for manufacturers aiming to optimize their processes and equipment longevity.

The choice of the right industrial turntable bearing can significantly impact productivity. A well-designed bearing not only improves the functionality of the machinery but also reduces maintenance costs and downtime. Factors such as load capacity, speed, and environmental conditions must be considered when selecting a bearing. With the right bearings, businesses can achieve higher efficiency, increased safety, and overall improved performance in their manufacturing operations.

7 Essential Tips for Choosing the Right Industrial Turntable Bearing

This chart illustrates the distribution of factors considered by manufacturers when selecting industrial turntable bearings, highlighting the importance of load capacity, material durability, cost, and maintenance needs.

Key Factors to Consider When Selecting Turntable Bearings for Industrial Use

When selecting turntable bearings for industrial use, there are several key factors that one must prioritize to ensure optimal performance and longevity. The first consideration is the load capacity of the bearing. It's essential to choose a bearing that can handle the weight of the turntable and any additional equipment or components attached to it. This ensures that the turntable operates smoothly without risking damage to either the bearing or the entire assembly.

Another important aspect is the precision of the bearing. High-precision turntable bearings can greatly enhance the accuracy of motion, which is crucial in various industrial applications. Look for bearings that offer low runout and high rotational accuracy. Additionally, consider the materials used in the bearings. Materials that resist wear and provide durability under heavy loads are essential for minimizing downtime and maintenance costs. With the increasing popularity of vinyl and the resurgence of high-quality turntables, it's vital to understand these factors to make informed decisions that align with your specific industrial needs.

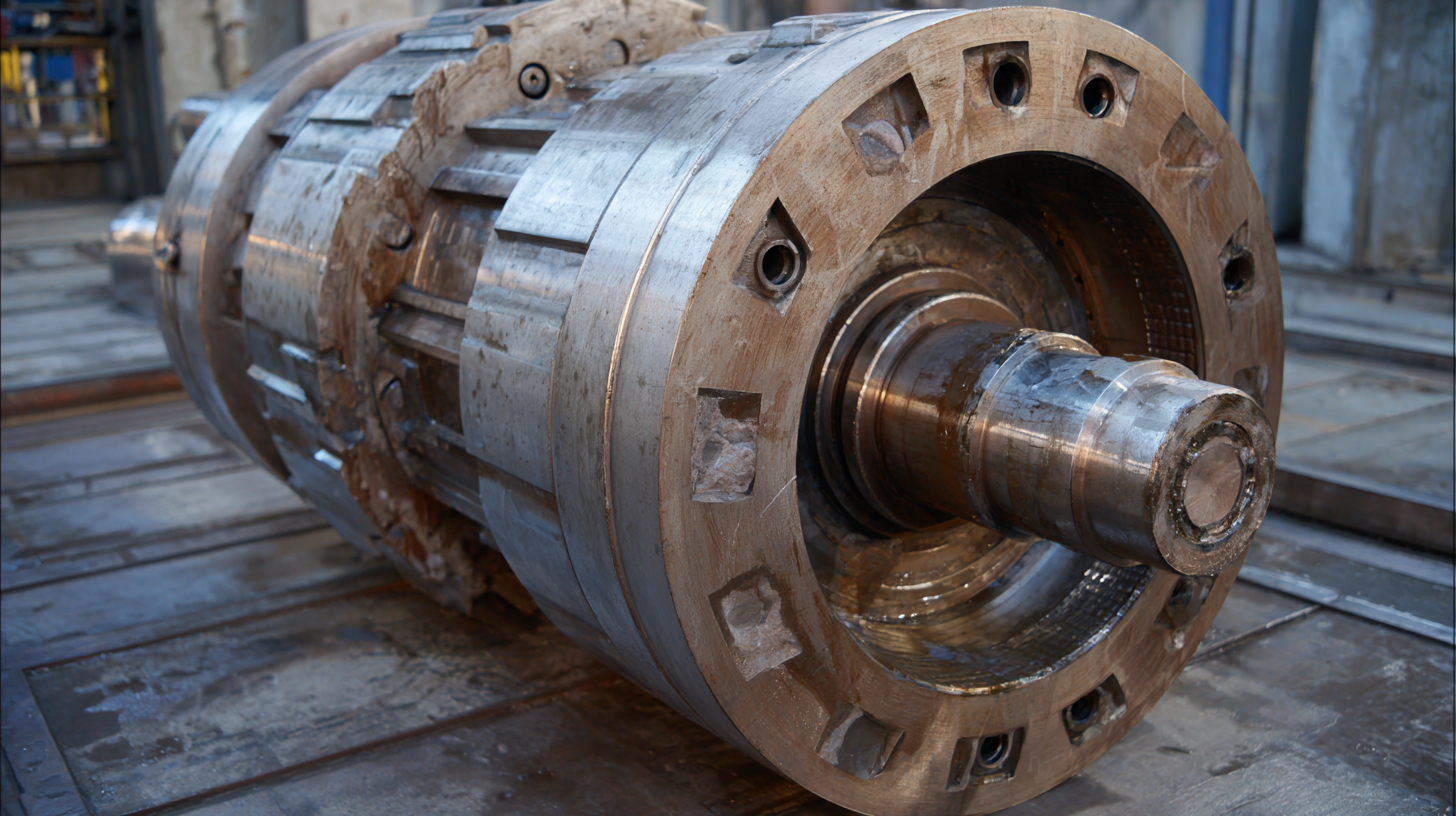

Different Types of Industrial Turntable Bearings and Their Applications

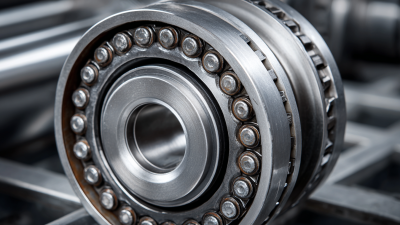

When selecting an industrial turntable bearing, understanding the various types available is crucial for ensuring

optimal performance in your operation. The three most common types are plain bearings,

roller bearings, and ball bearings.

Plain bearings offer simplicity and cost-effectiveness, making them ideal for applications where high precision

isn't critical. However, for applications that require higher load capacities and durability, roller bearings are

preferred due to their ability to support heavy loads with reduced friction.

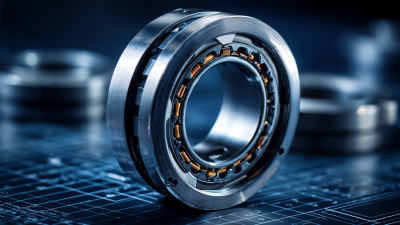

Ball bearings, on the other hand, are often utilized in applications requiring high-speed rotation and minimal resistance.

Their design allows for smooth movement, making them suitable for industrial equipment such as cranes or heavy machinery.

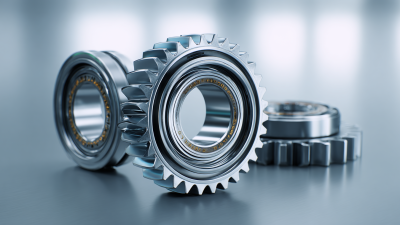

Each type of bearing serves different purposes, and understanding their unique characteristics can guide you in selecting

the right bearing that aligns with your specific operational needs. The application context, load requirements,

and environmental factors should all be considered carefully during the selection process.

Ball bearings, on the other hand, are often utilized in applications requiring high-speed rotation and minimal resistance.

Their design allows for smooth movement, making them suitable for industrial equipment such as cranes or heavy machinery.

Each type of bearing serves different purposes, and understanding their unique characteristics can guide you in selecting

the right bearing that aligns with your specific operational needs. The application context, load requirements,

and environmental factors should all be considered carefully during the selection process.

Maintenance Tips to Prolong the Life of Industrial Turntable Bearings

When it comes to prolonging the life of industrial turntable bearings, maintenance is key. Regular inspection is crucial; check for any signs of wear or damage, such as rust or irregular movement. Applying the right lubricant at appropriate intervals can significantly reduce friction and prevent overheating, which are common culprits in bearing failure. It's essential to follow manufacturer guidelines for lubrication frequency and type, as using the wrong product can lead to premature wear.

Additionally, keeping the surrounding environment clean and dry helps minimize contamination that can compromise bearing integrity. Dirt and debris can infiltrate the bearing assembly, leading to increased wear over time. Implementing a routine cleaning schedule, along with proper sealing methods, can ensure your industrial turntable bearings operate smoothly for years to come. By taking these proactive steps, you can not only extend the lifespan of your bearings but also enhance overall equipment performance.

How to Assess the Load Capacity and Performance Specifications of Bearings

When selecting the right industrial turntable bearing, assessing load capacity and performance specifications is crucial. Understanding these factors ensures that you choose a bearing capable of handling the operational demands of your application.

Start by evaluating the maximum load the bearing will encounter in service conditions. Consider variables such as axial loads, radial loads, and any potential thermal impacts that may affect performance. For instance, recent studies highlight that the collective impact of lateral, axial, and thermal loading significantly influences the ultimate bearing capacity of various systems.

Another essential tip is to look for advanced modeling techniques that predict bearing performance under various conditions. Recent advancements in data-driven frameworks have demonstrated the utility of machine learning algorithms in predicting the bearing capacity of structures under different stress conditions. Integrating these insights into your selection process can provide a more reliable assessment of whether a specific bearing meets your performance requirements. By keeping these considerations in mind, you can enhance operational efficiency and prolong the lifespan of your equipment.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Ball bearings, on the other hand, are often utilized in applications requiring high-speed rotation and minimal resistance.

Their design allows for smooth movement, making them suitable for industrial equipment such as cranes or heavy machinery.

Each type of bearing serves different purposes, and understanding their unique characteristics can guide you in selecting

the right bearing that aligns with your specific operational needs. The application context, load requirements,

and environmental factors should all be considered carefully during the selection process.

Ball bearings, on the other hand, are often utilized in applications requiring high-speed rotation and minimal resistance.

Their design allows for smooth movement, making them suitable for industrial equipment such as cranes or heavy machinery.

Each type of bearing serves different purposes, and understanding their unique characteristics can guide you in selecting

the right bearing that aligns with your specific operational needs. The application context, load requirements,

and environmental factors should all be considered carefully during the selection process.