Envisioning the Future of Precision: Innovations in Best Bearing Design

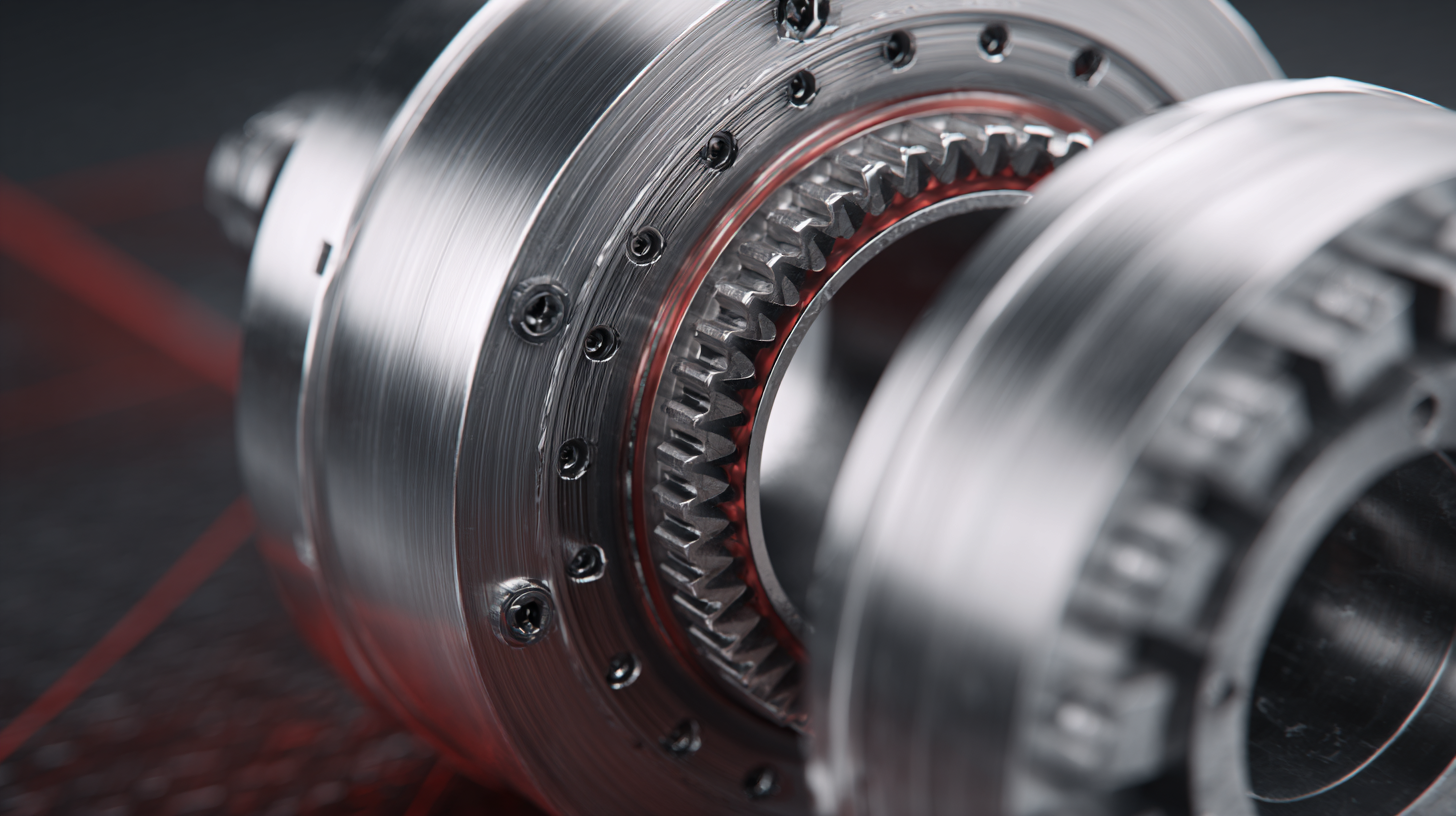

The future of Bearing Design is poised for remarkable advancements driven by cutting-edge innovations and a growing need for efficiency in various industrial applications. According to a report by the Global Bearing Market, the industry is expected to grow substantially, with a projected CAGR of around 7% from 2023 to 2030, highlighting the increasing demand for high-performance bearings in sectors like automotive, aerospace, and renewable energy. As businesses seek to enhance operational efficiency and reduce downtime, innovative approaches in materials, lubrication technologies, and smart bearing systems are becoming essential. This blog will explore the transformative trends shaping the future of precision in bearing design, showcasing how these innovations will not only improve performance but also contribute to sustainability and cost-effectiveness in manufacturing processes.

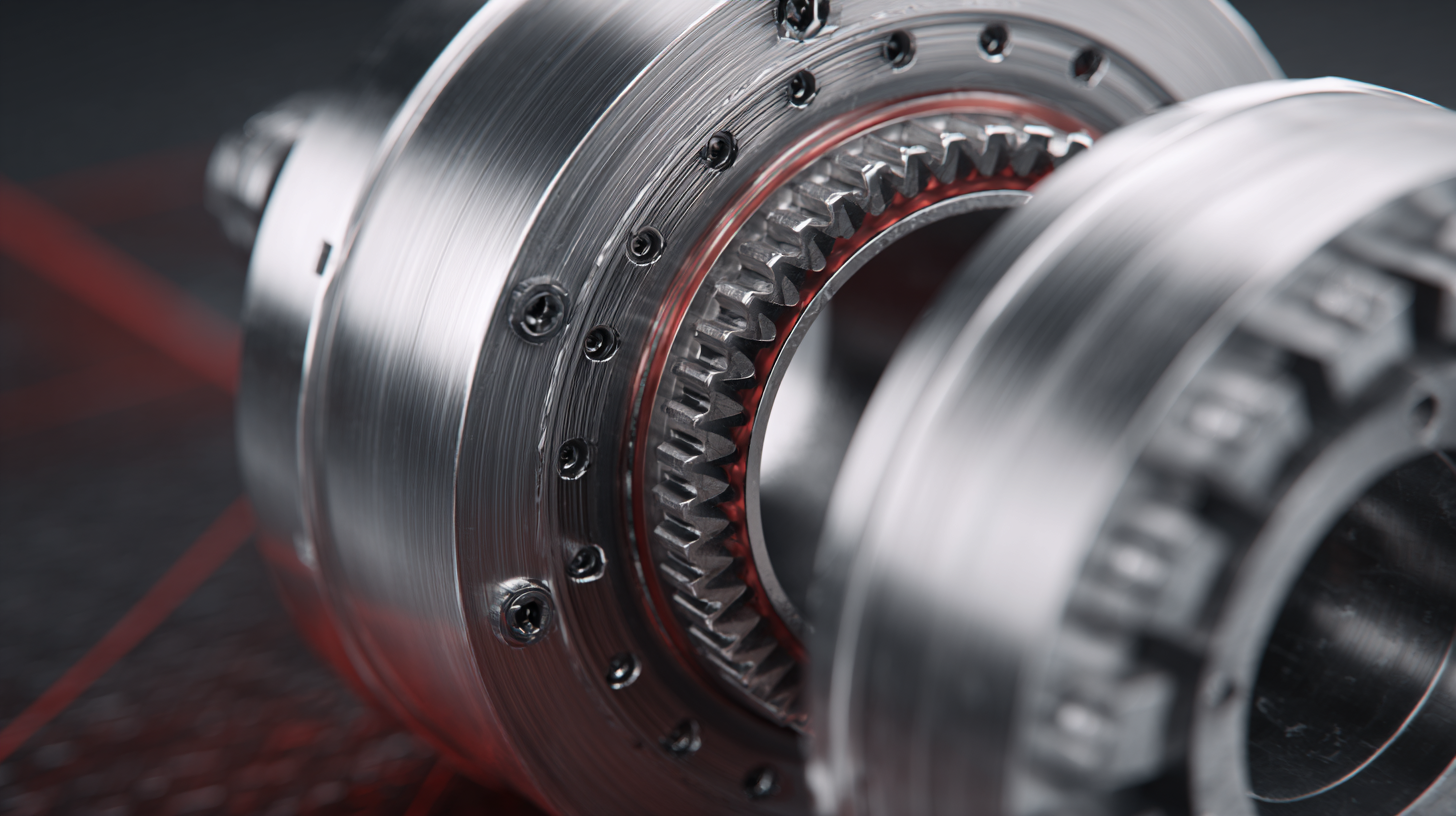

Future Trends in Bearing Materials: The Rise of Advanced Composites and Alloys

The rise of advanced composites and alloys is setting the stage for the next generation of bearing materials. According to a recent report by MarketsandMarkets, the global bearings market is projected to reach USD 90 billion by 2026, with a significant shift towards high-performance materials. These advanced materials offer improved durability and resistance to wear, making them ideal for demanding applications in industries such as aerospace, automotive, and renewable energy.

Recent innovations in composite materials, such as fiber-reinforced plastics and ceramic matrix composites, have shown promise in enhancing bearing performance. For instance, a study published in the Journal of Tribology highlighted that bearings made from polymer composites can exhibit up to 30% lower friction compared to traditional metal bearings, leading to reduced energy consumption and extended service life. Furthermore, advanced alloys engineered with specific elemental combinations are also gaining traction, offering superior strength-to-weight ratios and corrosion resistance.

As manufacturers continue to invest in research and development, the integration of these advanced materials into bearing designs will drive efficiency and sustainability across various sectors. Industry leaders are increasingly focusing on the lifecycle performance of bearings, with many aiming to reduce emissions and improve energy efficiency through innovative design. This shift not only illustrates the evolving landscape of bearing technology but also aligns with global trends towards more sustainable manufacturing practices.

The Role of AI and Machine Learning in Optimizing Bearing Design and Performance

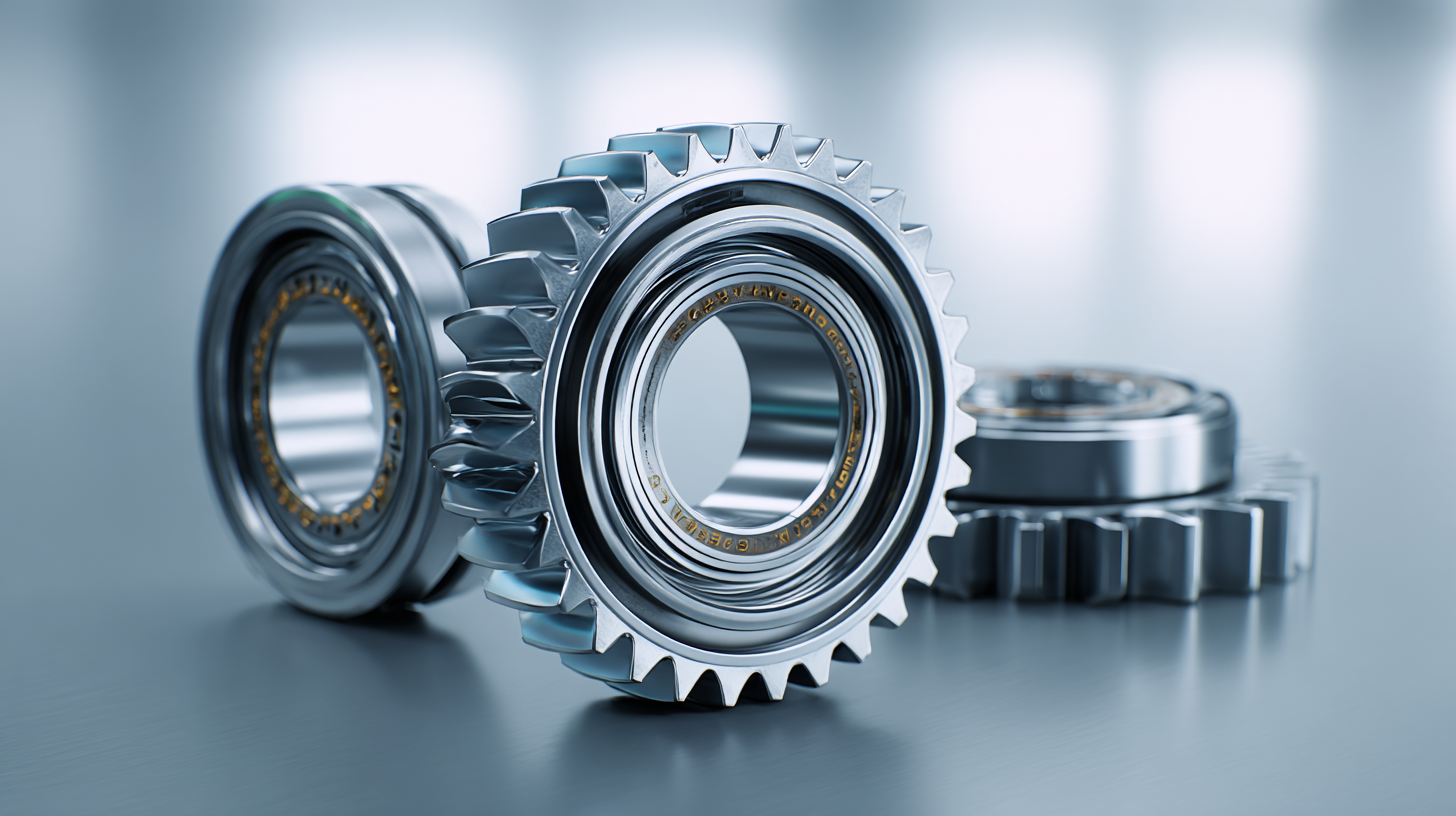

The integration of artificial intelligence (AI) and machine learning into bearing design represents a groundbreaking shift in engineering practices. These technologies enable engineers to analyze vast amounts of data related to bearing performance and failure patterns. By leveraging algorithms that learn from historical data, designers can predict the performance of different bearing configurations under varying conditions. This predictive capability allows for more informed decisions, leading to the creation of bearings that are not only more durable but also optimized for specific applications.

Additionally, machine learning empowers real-time monitoring of bearing systems, facilitating proactive maintenance and minimizing downtime. Sensors embedded in bearings collect data on temperature, vibration, and load, which AI systems can then analyze to identify anomalies. This continuous analysis helps in predicting potential failures before they occur, enhancing the reliability of machinery in industries ranging from aerospace to manufacturing. As these technologies evolve, the precision of bearing design will improve, resulting in components that effectively meet the increasing demands for efficiency and sustainability in modern engineering.

Envisioning the Future of Precision: Innovations in Best Bearing Design - The Role of AI and Machine Learning in Optimizing Bearing Design and Performance

| Bearing Type |

Material |

Load Capacity (kg) |

Temperature Range (°C) |

AI Optimization Techniques |

Efficiency Improvement (%) |

| Spherical Roller Bearing |

Steel |

1500 |

-30 to 120 |

Neural Networks |

15 |

| Deep Groove Ball Bearing |

Ceramic |

1200 |

-40 to 150 |

Genetic Algorithms |

20 |

| Tapered Roller Bearing |

Alloy Steel |

2000 |

-20 to 130 |

Fuzzy Logic |

18 |

| Thrust Bearing |

Bronze |

800 |

-10 to 110 |

Machine Learning |

22 |

| Angular Contact Bearing |

Stainless Steel |

1000 |

-30 to 150 |

Predictive Analytics |

16 |

Sustainability in Bearing Manufacturing: Eco-friendly Innovations and Practices

In the realm of precision engineering, sustainability has emerged as a cornerstone for innovation, particularly in bearing manufacturing. With growing environmental concerns, manufacturers are turning to eco-friendly materials and processes that not only reduce waste but also enhance performance. The focus is shifting from traditional materials to sustainable alternatives, such as biodegradable composites and recycled metals, which help minimize the ecological footprint of bearing production.

Additionally, advancements in manufacturing techniques, like additive manufacturing and precision molding, contribute to sustainability efforts. These methods enable the creation of components with reduced material waste and energy consumption. Furthermore, companies are implementing lean manufacturing practices which streamline operations and cut down on excess by-products.

By integrating these innovative approaches, the bearing industry is not only addressing environmental issues but also setting new benchmarks for efficiency and durability, ensuring that the future of precision continues to advance responsibly.

Additionally, advancements in manufacturing techniques, like additive manufacturing and precision molding, contribute to sustainability efforts. These methods enable the creation of components with reduced material waste and energy consumption. Furthermore, companies are implementing lean manufacturing practices which streamline operations and cut down on excess by-products.

By integrating these innovative approaches, the bearing industry is not only addressing environmental issues but also setting new benchmarks for efficiency and durability, ensuring that the future of precision continues to advance responsibly.

Advancements in Testing and Quality Assurance Techniques for Precision Bearings

In the relentless pursuit of excellence within the bearing industry, advancements in testing and quality assurance techniques are taking center stage. The advent of sophisticated technologies, such as non-destructive testing and digital simulations, has revolutionized the way precision bearings are evaluated. These innovations allow manufacturers to identify potential flaws that could compromise performance before their products ever reach the market. By implementing rigorous testing protocols, companies can ensure that each bearing meets stringent industry standards, ultimately enhancing reliability and reducing the risk of failure in critical applications.

Moreover, the integration of artificial intelligence (AI) and machine learning into the quality assurance process is enabling a shift towards more predictive analytics. These technologies analyze vast amounts of data collected during production and testing, allowing for real-time adjustments and continuous improvements in manufacturing practices. As a result, manufacturers can maintain tighter tolerances and achieve increasingly precise specifications, which is vital for applications ranging from aerospace to energy. With a focus on precision and innovation in testing methodologies, the future of bearing design is not only about creating superior products but also about ensuring they can withstand the rigors of their intended environments.

The Impact of 3D Printing on Custom Bearing Solutions and Rapid Prototyping

The advent of 3D printing technology has significantly transformed the manufacturing landscape, particularly in the realm of custom bearing solutions. According to a report by Markets and Markets, the global 3D printing market is projected to reach $34.8 billion by 2024, underscoring the growing adoption of additive manufacturing across various industries. This growth is not just limited to traditional sectors but extends to specialized applications, such as precision-engineered bearings that cater to specific performance requirements.

Rapid prototyping enabled by 3D printing allows engineers to design and test customized bearing designs swiftly, reducing the traditional lead time from weeks to mere hours. A study by Wohlers Associates indicates that 3D printing can cut prototyping costs by up to 90%, making it an attractive option for manufacturing unique bearing structures that enhance performance and durability. Innovations in materials, such as advanced polymers and composites, combined with the precision of 3D printing, enable the creation of bearings that are lighter yet stronger, catering to the ever-increasing demands of industries like aerospace, automotive, and robotics. This capability to produce bespoke solutions not only reduces waste but also aligns closely with the principles of sustainable manufacturing.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Additionally, advancements in manufacturing techniques, like additive manufacturing and precision molding, contribute to sustainability efforts. These methods enable the creation of components with reduced material waste and energy consumption. Furthermore, companies are implementing lean manufacturing practices which streamline operations and cut down on excess by-products.

By integrating these innovative approaches, the bearing industry is not only addressing environmental issues but also setting new benchmarks for efficiency and durability, ensuring that the future of precision continues to advance responsibly.

Additionally, advancements in manufacturing techniques, like additive manufacturing and precision molding, contribute to sustainability efforts. These methods enable the creation of components with reduced material waste and energy consumption. Furthermore, companies are implementing lean manufacturing practices which streamline operations and cut down on excess by-products.

By integrating these innovative approaches, the bearing industry is not only addressing environmental issues but also setting new benchmarks for efficiency and durability, ensuring that the future of precision continues to advance responsibly.