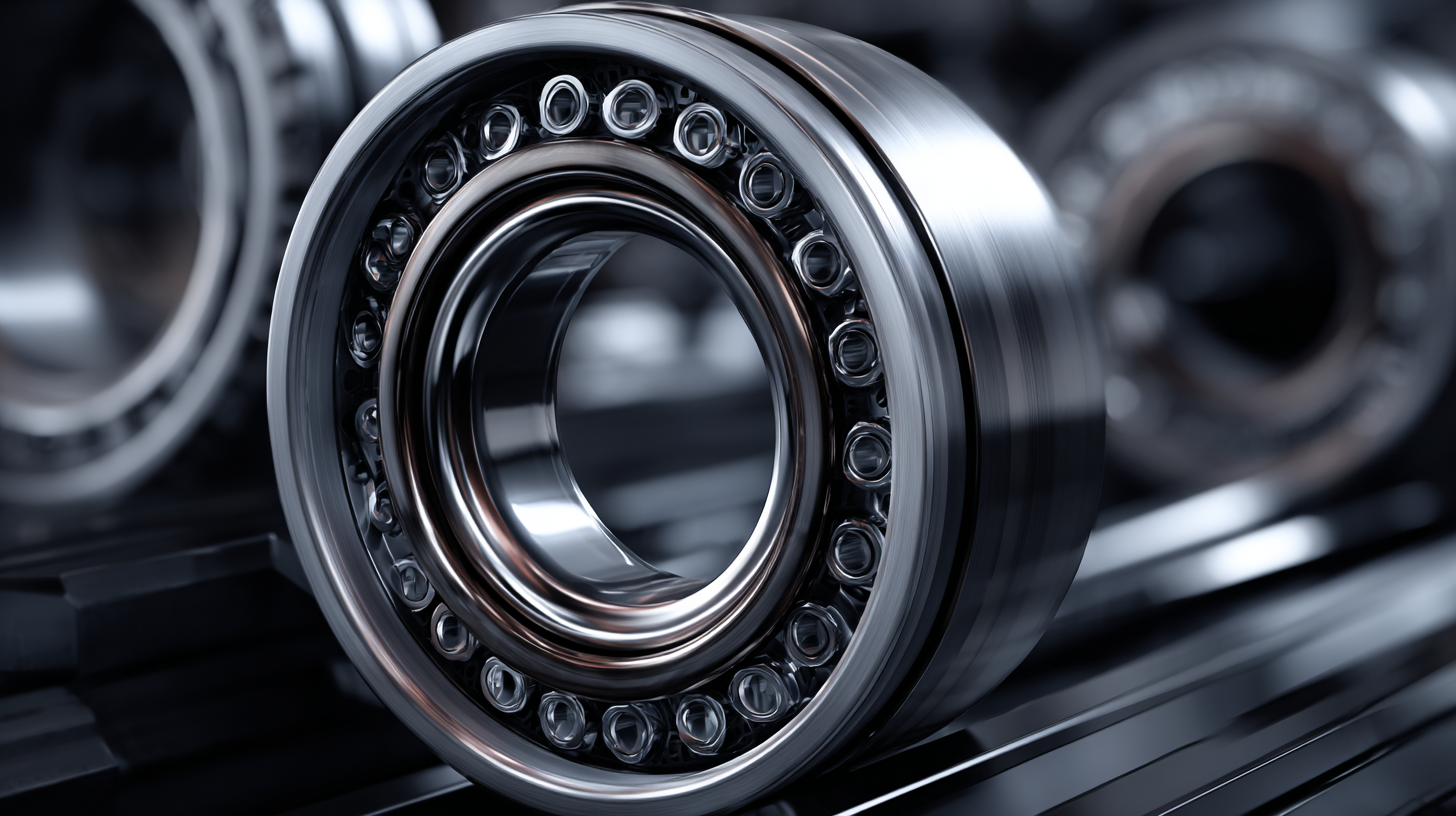

Exploring the Future of Steel Bearings in Advanced Manufacturing Technologies

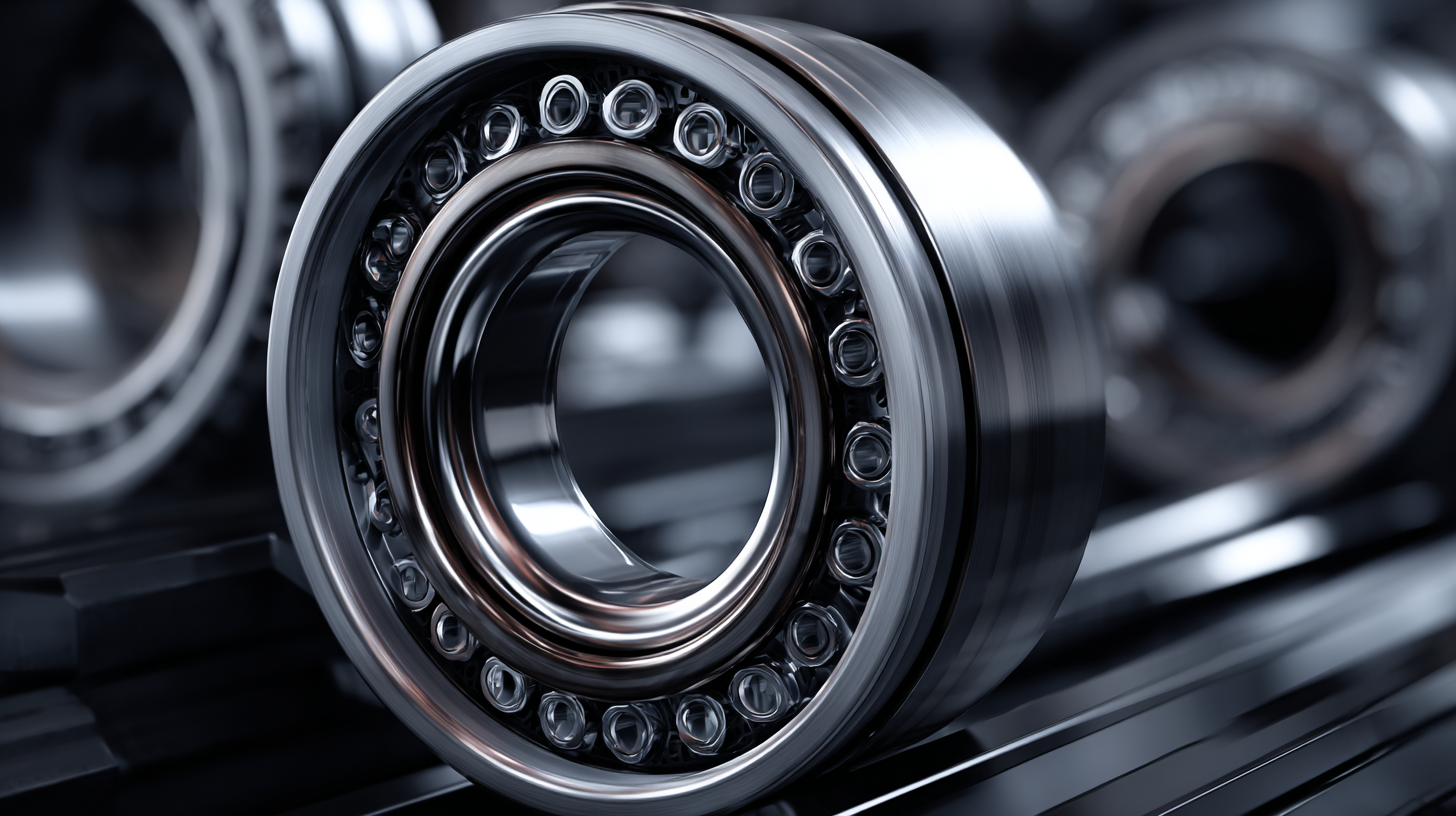

The evolution of advanced manufacturing technologies is reshaping various industries, and one critical component at the forefront of this change is steel bearings. As reported by the World Bearing Association, the global bearing market is projected to reach $106 billion by 2025, with steel bearings accounting for a significant portion due to their superior performance and reliability.

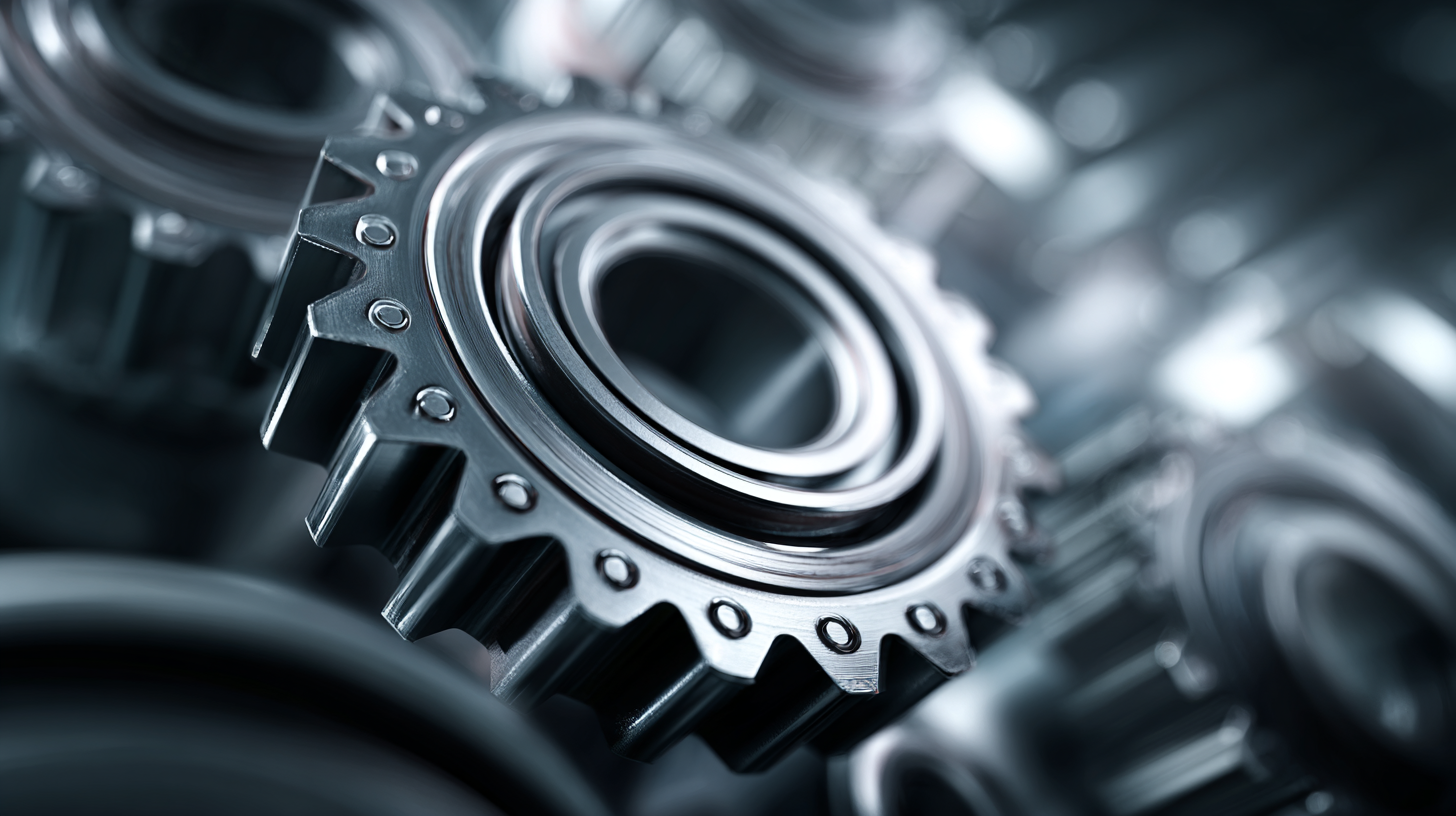

Innovations in materials science and precision engineering are driving the development of high-quality steel bearings that enhance productivity, reduce downtime, and improve energy efficiency across applications ranging from automotive to aerospace. As manufacturers strive to meet the demand for lighter, stronger, and more durable components, the role of steel bearings becomes increasingly paramount in sustaining competitive advantage in a rapidly evolving marketplace. Emphasizing the importance of this component within the context of advanced manufacturing will shed light on future trends and explore the potential for enhanced applications in emerging technologies.

Emerging Trends in Steel Bearing Manufacturing Techniques

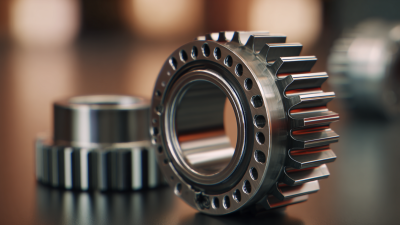

The steel bearing industry is undergoing a significant transformation driven by advanced manufacturing technologies. One of the most prominent emerging trends is the integration of additive manufacturing, commonly known as 3D printing. This technique allows for the production of complex geometries that were previously impossible or prohibitively expensive to achieve using traditional methods. By enabling custom designs and on-demand production, additive manufacturing not only reduces waste but also shortens lead times, making it an attractive option for industries requiring precision-engineered components.

Another noteworthy trend is the adoption of smart manufacturing practices. The implementation of IoT (Internet of Things) sensors within steel bearing manufacturing processes enables real-time data collection and analysis. This data-driven approach enhances predictive maintenance, minimizes downtime, and optimizes the supply chain. Moreover, machine learning algorithms can analyze performance metrics, leading to continuous improvements and innovations in bearing functionality. As manufacturers embrace these advanced technologies, the steel bearing sector is set to become more efficient, sustainable, and responsive to the evolving demands of various industries.

Impact of Advanced Materials on Steel Bearing Performance

The future of steel bearings in advanced manufacturing is closely intertwined with the emergence of innovative materials that enhance their performance. Advanced materials such as composites, ceramics, and specialized coatings are increasingly being integrated into steel bearing designs. By incorporating these materials, manufacturers can significantly improve the wear resistance, load capacity, and overall lifespan of steel bearings. This transformation is vital in industries where precision and durability are paramount, such as aerospace, automotive, and high-speed machinery.

Moreover, the impact of advanced materials extends beyond mere performance enhancements. These materials can facilitate lightweight designs, which contribute to energy efficiency in machinery and equipment. For instance, the use of hybrid materials can reduce the friction and heat generation in bearings, leading to lower operating temperatures and less energy consumption. As manufacturing technologies evolve, the integration of these cutting-edge materials will not only redefine the capabilities of steel bearings but also drive innovation in their applications, setting a new standard for efficiency and performance in advanced manufacturing.

Impact of Advanced Materials on Steel Bearing Performance

Automation and Its Role in Enhancing Steel Bearing Production

Automation plays a pivotal role in transforming the production landscape of steel bearings in advanced manufacturing technologies. With the advent of smart machinery and robotics, the steel bearing production process has become more efficient and precise.

Automated systems streamline operations by reducing human error and increasing production speeds. For instance, automated quality control systems utilize cutting-edge sensors and artificial intelligence to detect defects in real-time, ensuring that only high-quality bearings reach the market.

Moreover, automation facilitates the integration of data analytics into the production cycle. By leveraging machine learning algorithms, manufacturers can predict maintenance needs and optimize operational parameters. This data-driven approach not only maximizes productivity but also significantly lowers operating costs. As industries increasingly demand customized solutions, automated systems can rapidly adjust to accommodate varying specifications, thus enhancing flexibility. In summary, the interplay between automation and steel bearing production is set to redefine efficiency and innovation in manufacturing.

Sustainability Practices in Steel Bearing Manufacturing

As the steel bearing industry evolves within advanced manufacturing technologies, sustainability has emerged as a crucial focus. Today's manufacturers are increasingly recognizing the importance of integrating eco-friendly practices into their production processes. Several companies are embracing automation and digitalization not only to enhance efficiency but also to reduce their carbon footprint. This transformation is pivotal in meeting the demands of high-end application sectors while ensuring environmental responsibilities are upheld.

Innovations in materials and methods are driving greener solutions within the industry. Manufacturers are exploring sustainable materials and hybrid technologies to minimize waste and energy consumption. For instance, advancements in coating technologies aim to improve energy efficiency and reduce losses, subsequently lowering greenhouse gas emissions. The commitment to sustainability is not merely a trend but a necessity for companies looking to lead in an increasingly competitive and environmentally-conscious marketplace. This focus on sustainability in steel bearing production aligns with broader industry goals of achieving a more sustainable and resilient manufacturing landscape.

Exploring the Future of Steel Bearings in Advanced Manufacturing Technologies - Sustainability Practices in Steel Bearing Manufacturing

| Dimension |

Current Practices |

Future Trends |

Sustainability Strategies |

| Material Sourcing |

Recycled steel used in production |

Increased use of bio-based materials |

Lifecycle assessments for material choices |

| Manufacturing Process |

Conventional machining techniques |

Adoption of additive manufacturing |

Energy-efficient machines and processes |

| Waste Management |

Limited recycling program |

Zero waste initiatives |

Closed-loop recycling systems |

| Energy Usage |

Fossil fuel-based energy sources |

Shift to renewable energy sources |

Energy audits and optimization |

| Transportation |

Traditional logistics methods |

Use of electric vehicles |

Local sourcing to minimize transport impact |

Future Challenges and Opportunities for Steel Bearings in Industry

The future of steel bearings in advanced manufacturing technologies presents both challenges and opportunities for the industry. As highlighted in recent discussions at the Automotive Fastening and Connection Development Forum, the rise of advanced materials and innovative manufacturing processes is reshaping the landscape of bearing technology. Steel bearings are facing competition from elastic bearings, which offer unique advantages such as improved vibration absorption, noise reduction, and the capability to compensate for misalignment without the need for lubrication. These features make elastic bearings particularly appealing in various applications, prompting a reevaluation of traditional steel bearings in manufacturing.

However, the steel bearing industry still has a strong foundation that can be leveraged to address these challenges. With ongoing research and development, there are opportunities for steel bearings to innovate and adapt to new manufacturing technologies. Increasing the load capacity and enhancing resistance to wear and corrosion are critical areas where steel bearings can evolve. Additionally, as industries push toward automation and smarter manufacturing practices, integrating steel bearings with advanced IoT capabilities could further enhance their performance and reliability, ensuring they remain relevant in a rapidly changing technological landscape.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us