Ultimate Guide to Selecting the Right Bearing Tools for Optimal Performance

When it comes to ensuring optimal performance in machinery and equipment, selecting the right bearing tools is paramount. Bearings play a critical role in reducing friction and wear, thus enhancing the operational efficiency and lifespan of mechanical systems. However, with a myriad of options available in the market, the task of choosing the best bearing tools can often feel overwhelming.

This guide aims to streamline that process by providing you with the essential insights and best practices for selecting the most suitable bearing tools for your specific needs. Whether you are a seasoned professional or just starting out, understanding the different types of bearing tools and their applications will empower you to make informed decisions that lead to improved performance and reliability in your projects.

Understanding Different Types of Bearings and Their Applications

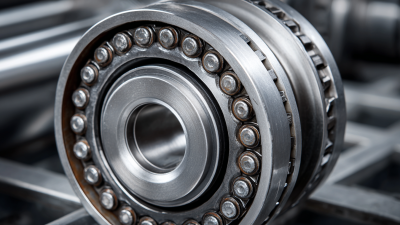

Selecting the right types of bearings for various applications is essential for ensuring optimal performance across different industries. Bearings serve as critical components in machinery, facilitating smooth motion and reducing friction. There are several types of bearings, each designed for specific applications. For instance, ball bearings are commonly used in electric motors and household appliances due to their ability to tolerate high speeds and loads.

In contrast, roller bearings are preferred in heavy-duty applications like construction equipment, where they can better handle radial loads.

Another important category is the thrust bearing, which is crucial in applications requiring axial load support, such as in marine and aerospace industries. Recent studies on hydrodynamic thrust bearings show that the combination of texture and slip formations significantly influences their tribological characteristics, enhancing their load-carrying capacity.

Moreover, technological advances in bearings for wind turbines highlight the growing importance of reliability and efficiency in renewable energy applications. As the global bearings market continues to expand, understanding the diverse types and their respective applications will be vital for making informed selection decisions.

Key Factors to Consider When Choosing Bearing Tools

When selecting bearing tools for optimal performance, there are several critical factors to keep in mind. Firstly, the type of bearing application plays a significant role in tool selection. Different applications may require varying levels of precision, load capacity, and speed compatibility. It's essential to assess the specific requirements of your operation, as choosing the wrong tool can lead to premature failure and increased maintenance costs.

Another crucial aspect is the material and design of the bearing tools. The global bearings market, valued at USD 46.82 billion in 2024, is forecasted to grow to USD 97.10 billion by 2030. This growth is driven by advancements in materials and technologies that enhance the durability and efficiency of bearing tools. Investing in high-quality materials can improve performance and reduce failure rates, making it a crucial consideration when selecting tools.

Furthermore, compatibility with existing systems should not be overlooked. Ensuring that the bearing tools integrate seamlessly with your machinery will minimize downtime and optimize operational efficiency. By considering these factors—application requirements, material quality, and system compatibility—you can make informed choices that enhance performance and reliability in your operations.

Essential Tools for Proper Bearing Installation and Removal

Proper bearing installation and removal is crucial for maintaining the longevity and performance of rotating machinery. According to a report by the American National Standards Institute (ANSI), improper installation contributes to almost 40% of premature bearing failures. Thus, equipping technicians with the right tools is essential to minimize errors and enhance operational efficiency.

When it comes to bearing installation, essential tools include bearing heaters, pullers, and alignment tools. A study by the Machinery Failure Prevention Technology (MFPT) revealed that using a bearing heater can reduce the required force for installation by up to 70%, greatly decreasing the risk of damage. Additionally, precision alignment tools ensure that bearings are mounted correctly, which can lead to a 30% reduction in vibration levels, subsequently prolonging the life of both the bearing and the machinery it supports.

For the removal process, bearing pullers are indispensable. They come in various configurations, including two-arm and three-arm pullers, each suited to different bearing sizes and types. Data from the Engineering Toolbox indicates that the correct use of pullers can improve removal efficiency and reduce associated downtime by up to 25%. Investing in top-quality bearing tools not only streamlines the installation and removal processes but also significantly contributes to overall machinery performance.

Maintenance Practices for Prolonging Bearing Life and Performance

Maintaining the longevity and performance of bearings is crucial for ensuring the smooth operation of machinery. Regular maintenance practices can significantly reduce wear and tear, ultimately extending the lifespan of your components.

One essential tip is to implement a scheduled lubrication routine. Use the appropriate grease or oil, as specified by the manufacturer, and ensure that bearings are never under-lubricated, which can lead to overheating and damage.

Another valuable practice is to conduct routine inspections. Regularly check for signs of wear, misalignment, or contamination. Utilize tools such as vibration analysis and thermal imaging to detect potential issues early. These proactive measures can help you address problems before they escalate, ensuring optimal performance and preventing costly downtime.

Additionally, consider the storage and handling of bearings. Always store them in a clean, dry environment to prevent contamination. Proper handling techniques also matter; avoid dropping or mishandling bearings, as this can lead to surface damage that compromises performance. By integrating these maintenance practices, you can significantly prolong the life of your bearings and enhance overall machinery efficiency.

Selecting the Right Lubrication Techniques for Optimal Bearing Function

When it comes to ensuring optimal function and longevity of bearings, selecting the right lubrication techniques is paramount. Bearings are essential components in machinery, reducing friction between moving parts. However, the effectiveness of these components heavily relies on proper lubrication. Among the various lubrication methods, grease and oil are the primary choices, each offering distinct benefits depending on the application and environment.

Grease is often preferred in situations where long-term lubrication is essential or where frequent reapplication is challenging. It helps prevent debris buildup and offers a sealing effect that protects bearings from contaminants. On the other hand, oil lubrication provides superior cooling properties and is advantageous in high-speed applications. Choosing the right viscosity and type of oil can significantly influence performance, as it impacts how well it can flow and reach all bearing surfaces.

Additionally, the application frequency and technique are crucial to maintaining optimal bearing function. Automated lubrication systems can provide precise amounts of lubricant at set intervals, ensuring that bearings operate in their ideal range. Regular monitoring and analysis of lubricant condition can also aid in identifying potential issues before they lead to failure. By understanding the intricacies of lubrication methods, businesses can enhance the efficiency and lifespan of their bearings, ultimately driving better performance in their machinery.

Ultimate Guide to Selecting the Right Bearing Tools for Optimal Performance - Selecting the Right Lubrication Techniques for Optimal Bearing Function

| Bearing Type |

Recommended Tool |

Lubrication Technique |

Performance Benefits |

| Deep Groove Ball Bearing |

Bearing Installer |

Grease Lubrication |

Reduces friction and wear |

| Tapered Roller Bearing |

Bearing Puller |

Oil Mist Lubrication |

Increases load capacity |

| Angular Contact Bearing |

Alignment Tool |

Thin Oil Lubrication |

Enhances speed capabilities |

| Spherical Roller Bearing |

Torque Wrench |

High-Viscosity Grease |

Improves performance under high loads |

| Self-Aligning Bearing |

Bearing Tester |

Solid Film Lubrication |

Reduces maintenance requirements |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us