Understanding the Importance of Automotive Bearings for Vehicle Performance and Longevity

In the intricate world of automotive engineering, the significance of automotive bearings often goes underappreciated, yet they play a pivotal role in enhancing vehicle performance and ensuring longevity. These critical components support the rotating shafts and facilitate smooth motion, reducing friction and wear throughout the vehicle's systems. Understanding the importance of automotive bearings not only sheds light on their function but also highlights their impact on fuel efficiency, handling, and overall vehicle durability. As we delve into the various types and technological advancements in automotive bearings, it becomes clear that investing in high-quality bearings can make a remarkable difference in a vehicle’s operation and lifespan. This exploration will provide crucial insights for both automotive professionals and enthusiasts on optimizing vehicle performance and ensuring reliability through the careful selection and maintenance of automotive bearings.

In the intricate world of automotive engineering, the significance of automotive bearings often goes underappreciated, yet they play a pivotal role in enhancing vehicle performance and ensuring longevity. These critical components support the rotating shafts and facilitate smooth motion, reducing friction and wear throughout the vehicle's systems. Understanding the importance of automotive bearings not only sheds light on their function but also highlights their impact on fuel efficiency, handling, and overall vehicle durability. As we delve into the various types and technological advancements in automotive bearings, it becomes clear that investing in high-quality bearings can make a remarkable difference in a vehicle’s operation and lifespan. This exploration will provide crucial insights for both automotive professionals and enthusiasts on optimizing vehicle performance and ensuring reliability through the careful selection and maintenance of automotive bearings.

The Critical Role of Automotive Bearings in Vehicle Mechanics

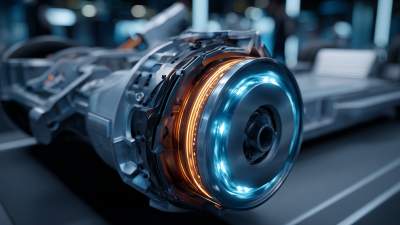

Automotive bearings play a critical role in vehicle mechanics, serving as essential components that ensure smooth operation and enhanced performance. These bearings are integral in reducing friction between moving parts, which not only improves efficiency but also lengthens the lifespan of various automotive systems.

As the automotive industry continues to thrive, the demand for high-quality bearings is escalating, particularly in light of increasing vehicle sales. The rapid expansion of the automotive market highlights the growing reliance on forged components like engine parts, transmission assemblies, and steering systems, each benefiting significantly from robust and durable bearings.

Moreover, the burgeoning ball bearing market reflects this trend, with projections indicating substantial growth from $7.26 billion in 2025 to $12.15 billion by 2032, driven by a compound annual growth rate of 7.6%. This rising demand underscores the importance of automotive bearings in achieving optimal vehicle performance and longevity.

As innovations in vehicle technology unfold, particularly with the surge in electric vehicles, the need for advanced bearing solutions will continue to escalate, establishing them as a cornerstone of automotive mechanics in the modern era.

5 Types of Bearings Essential for Optimal Vehicle Performance

When it comes to vehicle performance and longevity, automotive bearings play a critical role. These components reduce friction between moving parts, enabling smoother operation and enhancing overall efficiency. There are five fundamental types of bearings essential for optimal vehicle performance:

roller bearings, ball bearings, tapered bearings, and thrust bearings, as well as sleeve bearings. Each type is designed for specific applications, ensuring that vehicles can handle varying loads and speeds.

As the global automotive market continues to expand, with a projected growth of the bearings market from USD 50.16 billion in 2025 to USD 97.10 billion shortly thereafter, the significance of reliable and efficient bearings cannot be overstated. In particular, the degradation of bearings is a frequent cause of failures in electrical machines, making proactive condition monitoring a necessity for maintaining vehicle reliability. Advanced detection methods, such as hybrid LSTM random forest models combined with grey wolf optimization, are being developed to enhance the early detection of multiple bearing faults, further emphasizing the importance of these components in vehicle maintenance and performance.

How Proper Lubrication Enhances Bearing Longevity in Cars

Proper lubrication is essential for optimizing the performance and longevity of automotive bearings. According to the National Lubricating Grease Institute, approximately 70% of bearing failures are attributed to poor lubrication practices. This emphasizes the critical role that grease and oil play in maintaining the integrity of bearings, which are vital components in any vehicle's performance. When bearings are inadequately lubricated, they can experience increased friction, leading to overheating and eventual failure. Regularly checking and maintaining the right type of lubricant can significantly extend bearing life, ensuring smoother operation and preventing unexpected vehicle breakdowns.

Tip: Always choose a lubricant that is appropriate for your driving conditions. For example, synthetic oils tend to perform better under extreme temperatures and can provide superior protection against wear.

Incorporating proper lubrication techniques not only enhances the bearing's lifespan but also improves overall vehicle efficiency. The Society of Automotive Engineers reports that well-lubricated bearings can reduce energy consumption by as much as 30%, providing both economic and environmental advantages. Thus, routine maintenance, including timely oil changes and grease replenishment, is crucial for vehicle owners who aim to maximize their car’s performance and longevity.

Tip: Consider establishing a maintenance schedule based on your driving habits and the manufacturer's recommendations to ensure bearings are adequately lubricated and functioning effectively.

Understanding the Importance of Automotive Bearings for Vehicle Performance and Longevity - How Proper Lubrication Enhances Bearing Longevity in Cars

| Bearing Type |

Lubrication Method |

Life Expectancy (miles) |

Performance Impact (%) |

Maintenance Frequency (miles) |

| Ball Bearing |

Grease Lubrication |

150,000 |

25% |

30,000 |

| Roller Bearing |

Oil Lubrication |

200,000 |

30% |

25,000 |

| Thrust Bearing |

Wet Sump Lubrication |

120,000 |

20% |

20,000 |

| Spherical Bearing |

Oil Mist Lubrication |

180,000 |

28% |

40,000 |

| Magnetic Bearing |

Self-Lubricating |

250,000 |

35% |

Never |

Top 3 Signs Your Vehicle's Bearings Need Immediate Attention

Automotive bearings play a crucial role in ensuring vehicle performance and longevity. They facilitate smooth rotation, reduce friction, and support various components such as wheels, transmissions, and engines. However, neglecting the signs of bearing wear can lead to severe problems, not only undermining performance but also jeopardizing safety.

One of the top signs that your vehicle's bearings need immediate attention is unusual noises, such as grinding or squeaking sounds coming from the wheels or engine. This could indicate that the bearings are deteriorating and need to be replaced. Another warning sign is vibration in the steering wheel or throughout the vehicle, which suggests that the bearings may be misaligned or damaged. Lastly, if you notice uneven tire wear, it might point to issues with the wheel bearings affecting the tire’s contact with the road.

Recognizing these symptoms early on can prevent more extensive damage and costly repairs, ensuring your vehicle remains in optimal condition. Ensuring your bearings are well-maintained is essential for a safe and comfortable driving experience.

5 Maintenance Tips to Extend the Life of Automotive Bearings

Automotive bearings play a crucial role in ensuring vehicle performance and longevity. Proper maintenance of these components can significantly extend their lifespan, ultimately enhancing overall vehicle efficiency. According to a report from the National Automotive Dealer Association (NADA), regular maintenance can improve the lifespan of automotive bearings by up to 30%. Here are five essential maintenance tips to achieve just that.

Firstly, regular inspection is vital. Mechanics recommend checking bearings for wear and tear at least once a year, with particular attention during routine oil changes.

Secondly, keeping bearings adequately lubricated is fundamental; using high-quality grease that matches the manufacturer's specifications can reduce friction and heat, thereby preventing premature failure.

Furthermore, it is imperative to monitor installation torque and alignment, as improper installation can lead to uneven wear and reduced performance. Lastly, maintaining clean working environments helps in preventing contaminants from damaging the bearings, which, according to industry studies, is responsible for nearly 50% of bearing failures.

By following these tips, vehicle owners can maximize the performance and longevity of their automotive bearings.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

In the intricate world of automotive engineering, the significance of

In the intricate world of automotive engineering, the significance of