Understanding the Importance of Bearing Lock Mechanisms in Industrial Applications

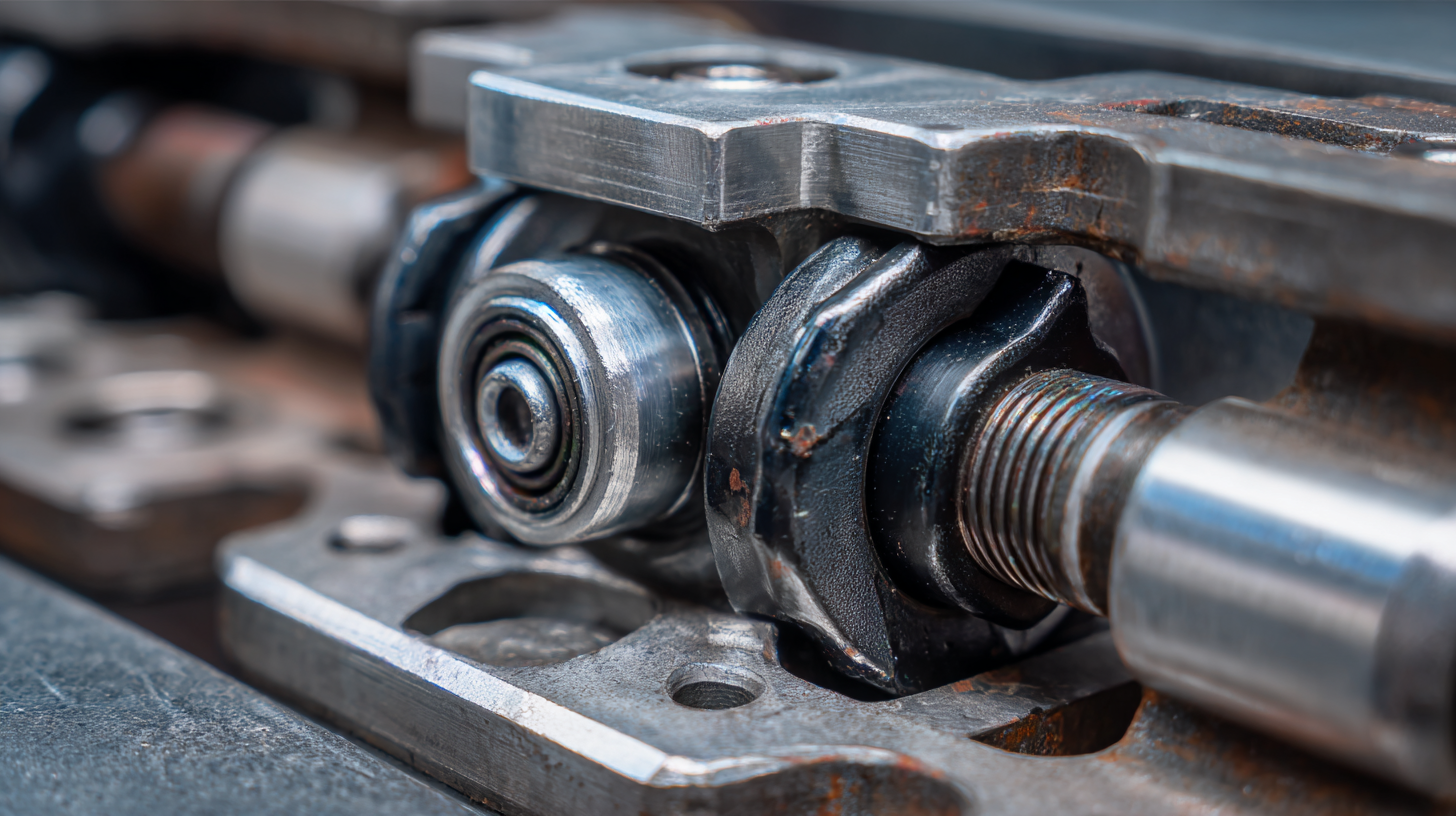

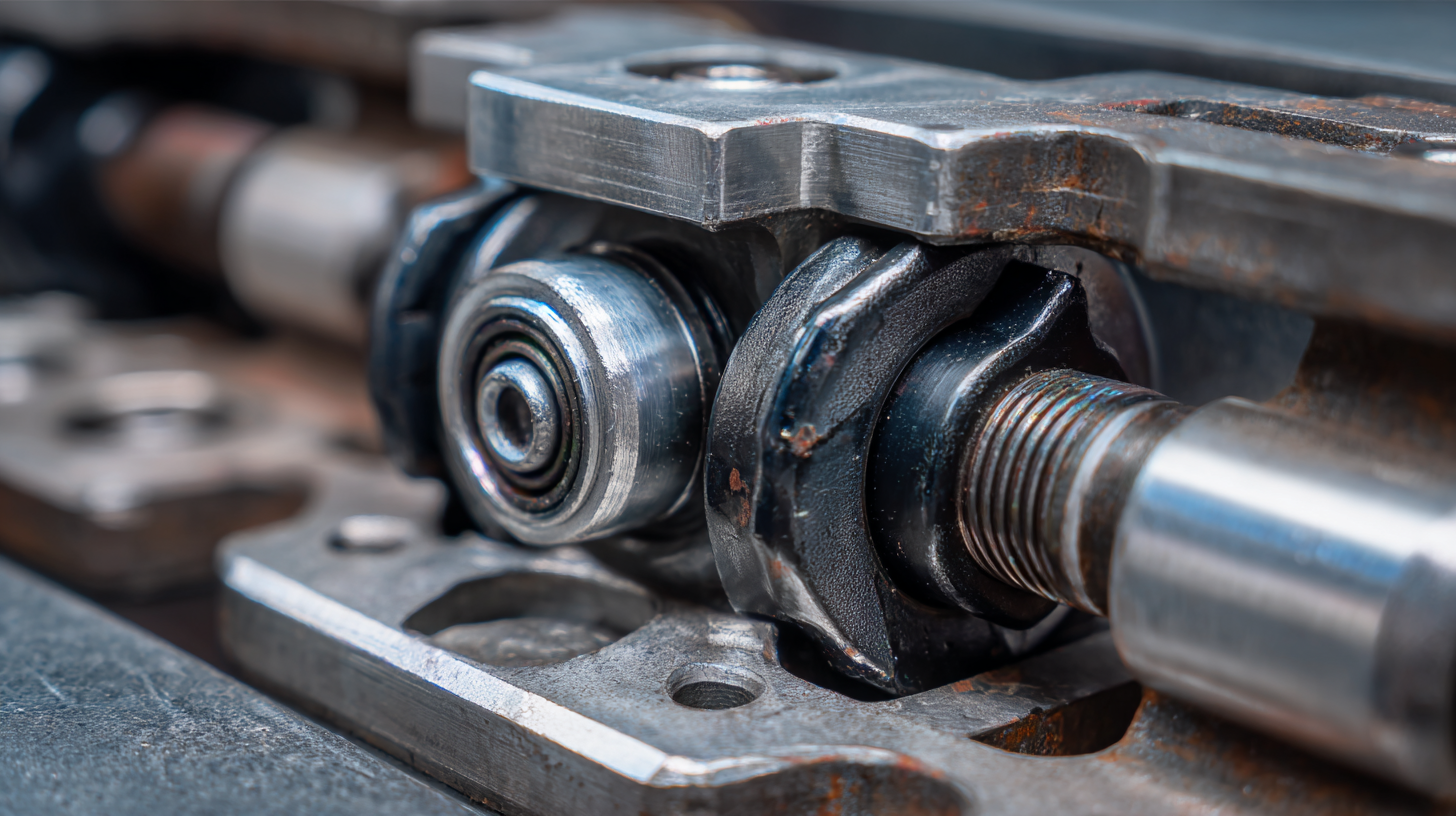

In the realm of industrial applications, the significance of bearing lock mechanisms cannot be overstated. These specialized devices play a critical role in ensuring the stability and reliability of rotating machinery. A well-designed bearing lock not only secures the position of the bearing on the shaft but also prevents premature wear and tear, ultimately extending the lifespan of equipment.

This article delves into the various types of bearing lock mechanisms, exploring their operational principles and applications across different industries. By understanding the importance and functionality of these mechanisms, engineers and maintenance professionals can make informed decisions that enhance the performance and safety of their machinery. This guide aims to provide a comprehensive overview of bearing lock solutions, serving as a valuable resource for those looking to optimize their industrial processes.

How Bearing Lock Mechanisms Enhance Equipment Safety and Performance

Bearing lock mechanisms play a crucial role in enhancing the safety and performance of industrial equipment. These mechanisms prevent the unintended loosening of bearings, which can lead to significant operational failures. By securely fastening bearings in place, they not only improve machine reliability but also minimize the risks associated with equipment malfunction. This added layer of security is essential in high-stakes environments where safety and efficiency are paramount.

Tips for ensuring effective bearing lock mechanisms include regular inspections and maintenance. Regularly checking the tightness of locking mechanisms can help identify potential issues before they escalate into major problems. Additionally, selecting the appropriate type of locking mechanism based on the specific application can enhance overall performance. For example, using an appropriate lock type that matches the operating temperature and load can significantly extend the life of bearings.

Furthermore, proper installation is critical for optimal performance. Ensuring that bearings are aligned correctly and that the locking mechanisms are engaged firmly will prevent premature wear and enhance overall machinery efficiency. Emphasizing correct practices during setup can lead to long-term savings and improved productivity in industrial applications.

Impact of Bearing Lock Mechanisms on Equipment Performance

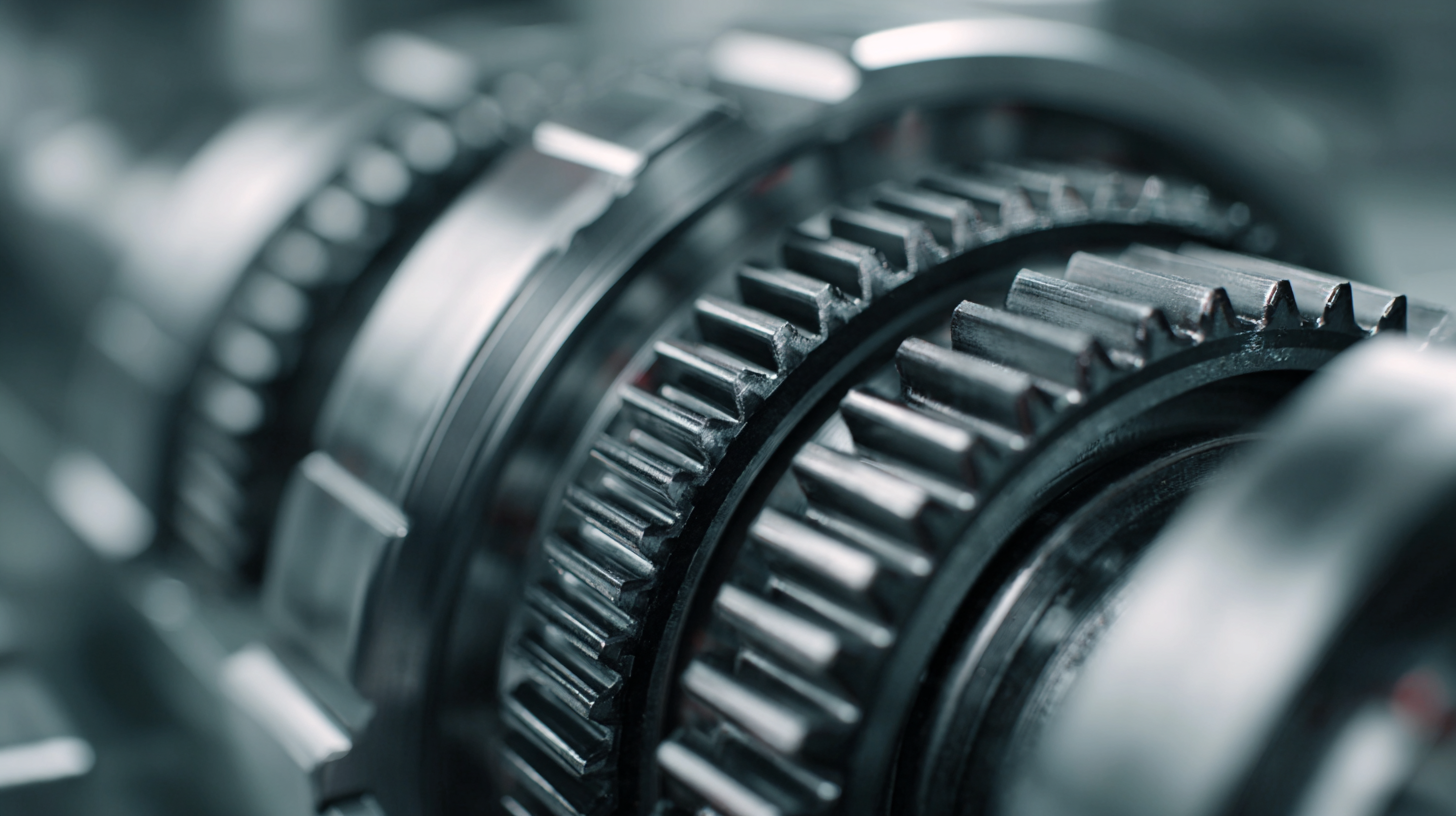

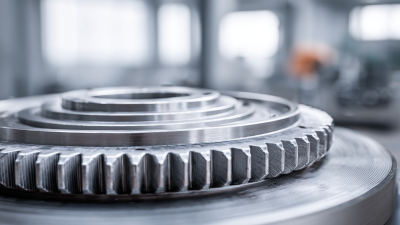

Key Types of Bearing Lock Mechanisms Used in Various Industries

Bearing lock mechanisms play a crucial role in ensuring the efficiency and longevity of various industrial applications. Notably, there are several key types of bearings, including set screw locks, eccentric locknuts, and tapered locking adapters, each serving distinct requirements across industries.

Set screw locks, for instance, provide a high level of torque resistance, making them ideal for heavy-duty machinery. According to industry reports, such as those from the Machinery Lubrication magazine, improper bearing installations can lead to equipment failures, costing manufacturers up to 20% of their annual maintenance budget.

Bearing lock mechanisms play a crucial role in ensuring the efficiency and longevity of various industrial applications. Notably, there are several key types of bearings, including set screw locks, eccentric locknuts, and tapered locking adapters, each serving distinct requirements across industries.

Set screw locks, for instance, provide a high level of torque resistance, making them ideal for heavy-duty machinery. According to industry reports, such as those from the Machinery Lubrication magazine, improper bearing installations can lead to equipment failures, costing manufacturers up to 20% of their annual maintenance budget.

In comparison, eccentric locknuts offer excellent performance in high-speed applications due to their ability to accommodate misalignment. These mechanisms are particularly valued in the automotive and aerospace sectors, where maintaining precise alignment is essential to the integrity of the machinery.

Furthermore, tapered locking adapters ensure ease of installation while providing robust support under varied load conditions, making them a preferred choice for conveyor systems and rotating equipment. The strategic selection of bearing lock mechanisms not only enhances operational efficiency but also significantly reduces downtime and maintenance costs, demonstrating their importance in industrial operations.

Factors to Consider When Selecting a Bearing Lock Mechanism

When selecting a bearing lock mechanism for industrial applications, several critical factors come into play. First, consider the operating environment. Harsh conditions, such as extreme temperatures, humidity, or exposure to dust and debris, can impact the performance and longevity of the lock mechanism. It's essential to choose materials that can withstand these conditions, ensuring reliability and reducing maintenance costs.

Another key factor is the load capacity of the bearing lock mechanism. Evaluate the specific loads that will be applied during operation, including static and dynamic loads. Selecting a mechanism that exceeds these requirements will enhance safety and durability. Additionally, ensure that the mechanism is compatible with the bearing type and size to guarantee optimal performance.

Tips: Always consult the manufacturer's specifications to understand the limits and capabilities of the bearing lock mechanism. Regular inspections can also help identify potential issues before they become critical, prolonging the life of your equipment. Lastly, consider ease of installation and maintenance when choosing a mechanism, as these factors can significantly affect operational efficiency.

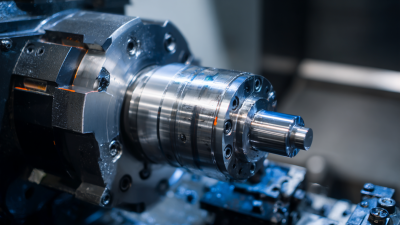

Step-by-Step Guide to Installing Bearing Lock Mechanisms

When it comes to installing bearing lock mechanisms in industrial applications,

precision and technique are paramount. According to a report by the Bearing Manufacturers Association (BMA),

improper installation can lead to a staggering 50% increase in bearing failure rates.

Therefore, following a systematic approach is essential for achieving optimal performance and longevity.

First, it’s crucial to ensure that the shaft and bearing surfaces are clean and free of contaminants.

A dirty interface can compromise the locking mechanism's effectiveness. Once prepared, the next step involves

placing the lock collar onto the bearing. Ensure that it is aligned correctly with the designated slot on

the shaft. According to a study conducted by the Industrial Maintenance News, incorrect alignment

accounts for nearly 25% of mechanical failures in rotating equipment.

Finally, after securing the collar with the appropriate torque specifications, double-checking the tightness

is essential to mitigate risks of loosening over time.

After installation, regular monitoring and maintenance are recommended. Maintenance records show that

industrial sectors implementing routine checks on their bearing lock mechanisms experience up to a

30% reduction in unexpected downtime. With these steps, industries

can enhance their operational efficiency and prolong the service life of critical machinery.

Maintenance Practices for Ensuring Long-Term Reliability of Bearing Locks

Bearing lock mechanisms play a crucial role in ensuring the reliability and performance of various industrial applications.

To maintain their functionality over time, regular maintenance practices are essential.

Implementing a thorough inspection routine can identify potential issues such as wear and misalignment before they develop into significant problems.

Check for signs of lubricant contamination and ensure that the locking mechanism is free of debris or obstructions.

Tip: Create a maintenance schedule that includes not just visual inspections but also checks for torque specifications and lubrication levels.

Keeping a log of these inspections can help track performance trends and make it easier to anticipate when maintenance is due.

In addition to routine inspections, it's important to adhere to manufacturer guidelines for lubrication and service intervals.

Using the correct type of lubricant and applying it in the recommended amounts will minimize friction and wear, enhancing the longevity of the bearing locks.

Tip: Invest in high-quality lubricants specifically designed for your bearing application.

Remember that over-lubrication can be just as damaging as under-lubrication,

so always follow the manufacturer's recommendations closely.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Bearing lock mechanisms play a crucial role in ensuring the efficiency and longevity of various industrial applications. Notably, there are several key types of bearings, including set screw locks, eccentric locknuts, and tapered locking adapters, each serving distinct requirements across industries.

Set screw locks, for instance, provide a high level of torque resistance, making them ideal for heavy-duty machinery. According to industry reports, such as those from the Machinery Lubrication magazine, improper bearing installations can lead to equipment failures, costing manufacturers up to

Bearing lock mechanisms play a crucial role in ensuring the efficiency and longevity of various industrial applications. Notably, there are several key types of bearings, including set screw locks, eccentric locknuts, and tapered locking adapters, each serving distinct requirements across industries.

Set screw locks, for instance, provide a high level of torque resistance, making them ideal for heavy-duty machinery. According to industry reports, such as those from the Machinery Lubrication magazine, improper bearing installations can lead to equipment failures, costing manufacturers up to