What are Industrial Turntable Bearings and Their Applications?

Industrial Turntable Bearings are crucial components in various sectors. These bearings support rotary motion and are essential for machinery in industries like construction, mining, and transportation. According to a recent market analysis, the global industrial bearing market was valued at approximately $60 billion in 2021, with projections indicating steady growth due to increased industrial automation.

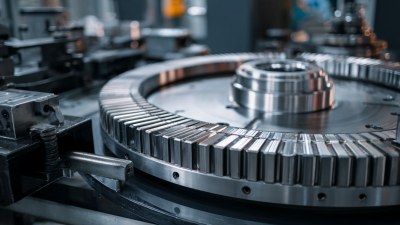

These bearings are designed to handle heavy loads and provide smooth rotation. Their applications range from flyovers and cranes to wind turbines and manufacturing equipment. The ability of an Industrial Turntable Bearing to ensure stability and precision is vital for machine performance. However, they are not without challenges. Factors like wear and tear can lead to performance issues over time, creating the need for regular maintenance and replacement.

Despite their significance, many industries overlook the importance of selecting the right bearings. A mismatch can lead to inefficiencies. Understanding the specific requirements of an application is essential for optimizing the performance of Industrial Turntable Bearings. As industries evolve, it is crucial to continually assess and address these challenges to maximize operational efficiency.

What are Industrial Turntable Bearings?

Industrial turntable bearings are essential components in heavy machinery and various industrial applications. These bearings allow for smooth rotation, making them vital in systems that require precise movements. They consist of a series of rolling elements, such as balls or rollers, which reduce friction. This design enables effective load distribution. Turntable bearings must withstand considerable stress and weight, often in harsh environments.

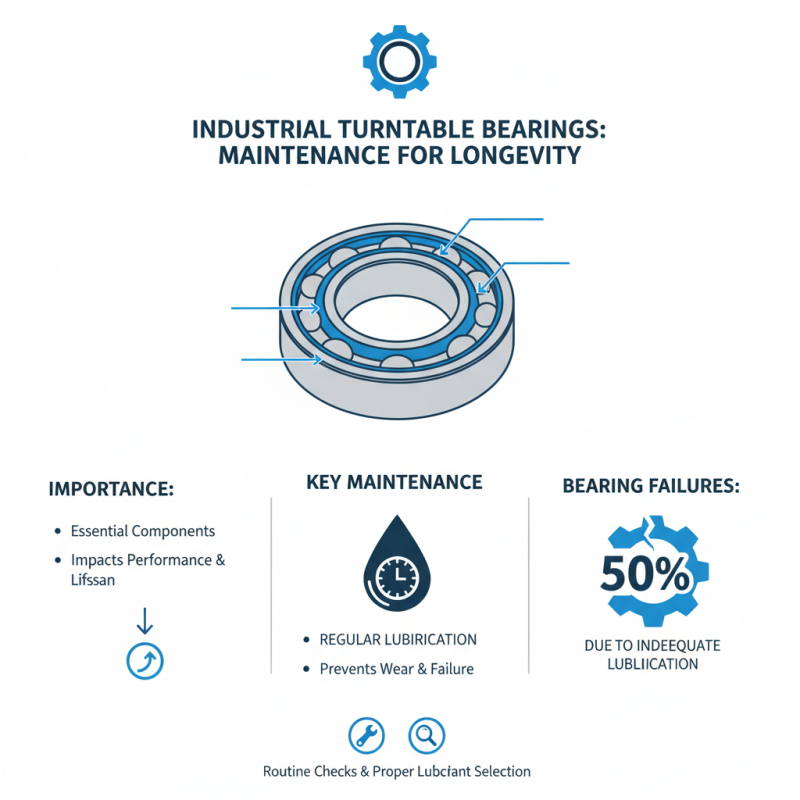

In practice, industrial turntable bearings are found in cranes, radar systems, and large conveyor systems. Their durability is crucial for reliable operation. However, these bearings can suffer from wear and tear over time. Regular maintenance is often overlooked, leading to unexpected failures. Maintenance involves cleaning and lubrication, tasks that can be tedious yet necessary.

Some users may encounter difficulties matching the right bearing with their specific application. Sizing can be a challenge, as different projects require different dimensions and load ratings. It’s easy to underestimate the importance of proper selection. Inadequate attention to detail can result in operational inefficiencies. Evaluating these bearings carefully is key to ensuring the longevity of machinery.

What are Industrial Turntable Bearings and Their Applications?

| Bearing Type |

Load Capacity (kg) |

Speed Rating (RPM) |

Materials |

Typical Applications |

| Single Row Turntable Bearing |

5000 |

150 |

Steel, Chrome |

Cranes, Hoists, Industrial Equipment |

| Double Row Turntable Bearing |

8000 |

100 |

Carbon Steel |

Excavators, Heavy Machinery |

| Cross Roller Bearing |

3000 |

200 |

Stainless Steel |

Robotic Arms, Medical Equipment |

| Four Point Contact Bearing |

6000 |

120 |

Bronze, Alloy Steel |

Wind Turbines, Solar Trackers |

| Thin Section Bearing |

2500 |

300 |

Aluminum, Polymer |

Aerospace, Precision Machines |

Understanding the Design and Functionality of Turntable Bearings

Turntable bearings are crucial in many industries. They enable smooth rotational movement between two parts. Their design typically includes two ring-like components. These rings allow a load to be distributed evenly. This feature is vital in applications requiring precision.

In construction equipment, turntable bearings support cab rotation. They must withstand heavy loads and harsh environments. Often, these bearings are exposed to dust and moisture. Regular maintenance is a challenge, yet essential for longevity. In wind turbines, they allow the blades to pivot. A small failure can lead to significant downtime. This highlights the need for careful selection and routine checks.

Attention to detail in the design can enhance functionality. However, manufacturers sometimes overlook material quality. Using subpar materials can lead to quicker wear and tear. Understanding these design flaws is important for improvement. It's not just about the rotation; it's about reliability, durability, and efficiency. The implications of using inferior bearings can be costly, affecting performance and safety in operations.

Key Applications of Turntable Bearings in Various Industries

Industrial turntable bearings play a crucial role in various sectors. They are designed to support rotating equipment. These bearings allow smooth and efficient motion. Common applications include cranes, construction machinery, and rotating platforms. In these environments, stability and precision are essential.

In the construction industry, turntable bearings support heavy loads with ease. They help ensure cranes can move materials efficiently. This reduces downtime and increases productivity. However, these bearings require regular maintenance. Neglect can lead to failures that disrupt operations.

In the renewable energy sector, turntable bearings are vital for wind turbines. They enable the blades to rotate and capture wind energy. This helps maximize power generation. Yet, the extreme conditions can wear bearings down. Adequate monitoring of performance is key to prolonging their lifespan. Industries must continuously assess their bearing choices and maintenance practices to achieve optimal performance.

Applications of Industrial Turntable Bearings Across Various Industries

Benefits of Using Turntable Bearings in Industrial Settings

Turntable bearings play a critical role in various industrial applications. They allow for smooth rotational movements, which enhance operational efficiency. One significant benefit is their ability to support heavy loads. According to industry reports, turntable bearings can withstand weights exceeding several tons, making them ideal for heavy machinery.

In industrial settings, using turntable bearings reduces friction and wear. This contributes to longer equipment life and reduced maintenance costs. Operations can expect a decrease in downtime, which directly impacts productivity. A study shows that businesses utilizing turntable bearings report up to 30% greater efficiency rates.

Tips: Regular maintenance checks on turntable bearings can prevent costly breakdowns. Keep an eye on lubrication levels to ensure optimal performance.

Moreover, turntable bearings are versatile. They find use in cranes, medical equipment, and even aerospace applications. However, the complexity of pairing the right bearings with specific tasks needs careful consideration. Improper selection can lead to failures. Always analyze the load and speed requirements before making a choice.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us