What You Need to Know About Industrial Turntable Bearings?

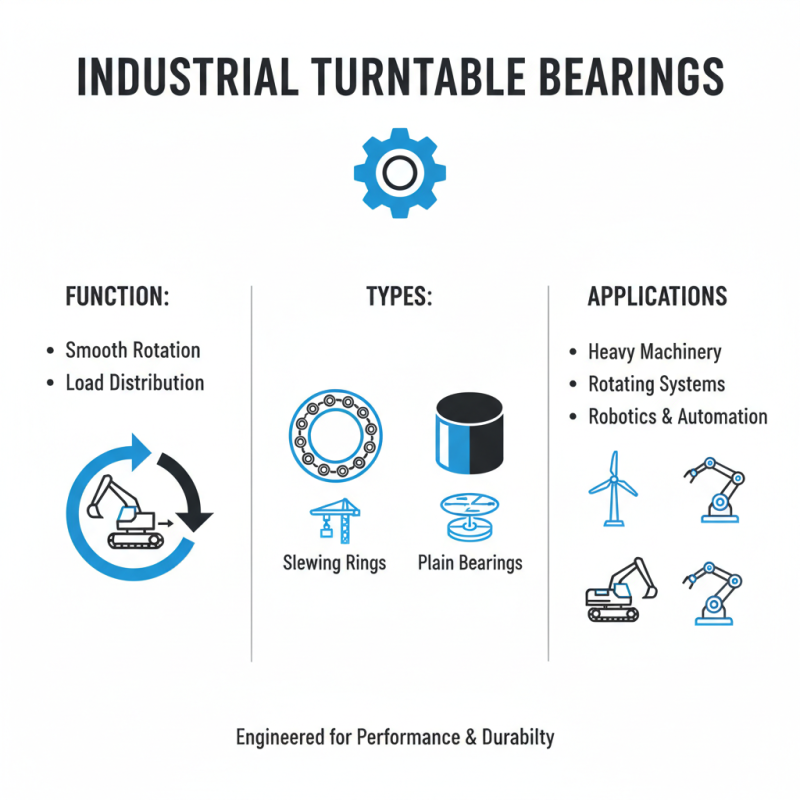

Industrial Turntable Bearings play a crucial role in various machinery and equipment. These components enable smooth rotation and support heavy loads. In industries like construction, transportation, and manufacturing, their importance cannot be overstated.

Understanding the specifications and applications of Industrial Turntable Bearings is vital. They come in different sizes and designs, tailored to meet specific operational needs. Choosing the right bearing can enhance performance and longevity in equipment. However, it's easy to overlook quality and compatibility when selecting these components.

It's essential to assess the bearing's load capacity and rotational speed. Ignoring these factors can lead to premature wear or equipment failure. Investing time in understanding these aspects can prevent costly downtime. We should reflect on our choices to ensure they align with industry standards and operational demands.

Overview of Industrial Turntable Bearings and Their Applications

Industrial turntable bearings play a crucial role in various applications. These bearings are designed to support heavy loads while enabling smooth rotation. They are commonly used in cranes, heavy machinery, and even in amusement park rides. Their design allows for easy movement, making them essential in processes that require precision and reliability. Each application demands specific bearing types tailored for optimal performance.

In cranes, for instance, heavy loads pivot on these bearings. The bearings must endure stress while facilitating swift movements. In contrast, turntables in leisure equipment require smooth, controlled rotation. The variations in design often lead to challenges in maintenance. Regular inspection is crucial but often overlooked. Neglect can lead to performance issues and safety risks, prompting a need for better practices. Adjustments in installation might be necessary, as improper assembly can cause significant failures.

Understanding the range of applications helps highlight the importance of these components. Despite their robust design, they are not invincible. Over time, they can wear out or suffer damage. It is vital to remain vigilant and proactive about their upkeep to ensure safety and efficiency.

Industrial Turntable Bearings Applications

Types of Industrial Turntable Bearings and Their Specifications

Industrial turntable bearings play a crucial role in heavy machinery and rotating systems. These specialized components allow for smooth rotation and load distribution. There are several types, each with unique specifications. The most common include slewing rings and plain bearings.

Slewing rings are designed for high axial and radial loads. They are often used in cranes and excavators. Their durability is impressive, which makes them reliable in harsh environments. Due to their complexity, they may require precise alignment during installation. Plain bearings, on the other hand, are simpler. They have a lower load capacity but are easier to maintain. Their design allows for cost-effective solutions in less demanding applications.

Understanding the specifications is vital for selecting the right type. Load capacity, diameter, and lubrication requirements should all be considered. These factors can impact overall performance. However, there can be a lack of clear guidelines available. Knowing when to seek expert advice is essential. Making the wrong choice can lead to significant mechanical failures.

Key Performance Metrics: Load Capacity and Rotational Speed

Industrial turntable bearings play a vital role in machinery and equipment. Understanding their key performance metrics is essential for optimal functionality. Load capacity and rotational speed are two critical aspects that determine a bearing's effectiveness.

Load capacity refers to the maximum weight a bearing can handle. Data from industry reports suggest that bearings should be selected based on exact load requirements. Overloading can lead to equipment failure. Conversely, undersized bearings can limit performance. Many manufacturers recommend conducting regular inspections of load conditions to ensure safety and efficiency.

Rotational speed impacts how fast a bearing can operate. High-speed applications often require precision and durability. Research indicates that bearings with high rotational speed ratings can dramatically improve productivity. However, selecting a bearing solely based on speed is risky if load capacity is not adequately considered. Balancing these metrics is key.

Tips: Consider your application’s total load and peak speeds. Customization might be necessary for demanding environments. Always monitor performance metrics to prevent unexpected downtime. When in doubt, consult a performance metrics chart for guidance; it helps in making informed choices.

What You Need to Know About Industrial Turntable Bearings?

| Bearing Type |

Load Capacity (kN) |

Rotational Speed (RPM) |

Diameter (mm) |

Material |

| Single Row Ball Bearing |

60 |

1500 |

200 |

Steel |

| Double Row Roller Bearing |

120 |

800 |

300 |

Stainless Steel |

| Thrust Bearing |

75 |

1000 |

250 |

Bronze |

| Spherical Roller Bearing |

90 |

1200 |

280 |

Alloy Steel |

| Cam Follower Bearing |

50 |

1400 |

180 |

Polyamide |

Maintenance Best Practices for Optimal Turntable Bearing Longevity

When it comes to industrial turntable bearings, maintenance is crucial for their longevity. Regular inspections should be part of your routine. Look for signs of wear or damage. Early detection can prevent larger issues later. It's easy to overlook these checks, especially in busy environments. Yet, neglect can lead to costly breakdowns.

Lubrication is another key aspect. It reduces friction and wear. Make sure to use the right type of lubricant. This choice can significantly affect performance. Over-lubrication can be just as harmful as under-lubrication. Striking a balance is essential for optimal function.

Lastly, keeping the work area clean is vital. Dust and debris can accumulate, negatively impacting performance. Regular cleaning should not be ignored. It may seem minor, but it can make a difference. By following these practices, you improve the lifespan of your turntable bearings.

Emerging Trends in Turntable Bearing Technology and Design Innovations

The bearing industry is witnessing rapid advancements. Emerging trends focus on enhanced materials and design innovations. A recent report by Market Research Future indicates that the global market for industrial bearings could reach $20 billion by 2026. This growth is driven by the demand for high-performance bearings in various applications.

One significant trend is the adoption of lightweight materials. Engineers are exploring composites and advanced polymers. These materials offer durability while reducing weight. A study by Deloitte highlighted that using lightweight bearings could improve energy efficiency by up to 15%. However, challenges remain in balancing strength with weight reduction.

Another innovation is smart bearing technology. Embedded sensors allow real-time monitoring of bearing conditions. This technology can predict failures, enhancing maintenance strategies. However, integration costs and data management are potential hurdles. Industry leaders must address these issues to maximize the benefits. The path forward is not without obstacles, but the potential for efficiency gains is substantial.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us