Innovations in Bearing Design at the 138th China Import and Export Fair 2025

As the global manufacturing landscape evolves, innovations in bearing design play a crucial role in enhancing machinery performance and sustainability. At the 138th China Import and Export Fair in 2025, industry leaders will showcase cutting-edge advancements that address the growing demand for efficient and durable bearings. According to a recent market analysis by Research and Markets, the global bearing market is projected to reach approximately $135 billion by 2025, driven by increasing applications in automotive, aerospace, and industrial machinery.

As the global manufacturing landscape evolves, innovations in bearing design play a crucial role in enhancing machinery performance and sustainability. At the 138th China Import and Export Fair in 2025, industry leaders will showcase cutting-edge advancements that address the growing demand for efficient and durable bearings. According to a recent market analysis by Research and Markets, the global bearing market is projected to reach approximately $135 billion by 2025, driven by increasing applications in automotive, aerospace, and industrial machinery.

The fair presents a unique opportunity for stakeholders to explore the latest technologies, including smart bearings with integrated sensors for predictive maintenance, and lightweight materials that reduce energy consumption. This event will not only highlight emerging trends but also provide a platform for discussing the future of bearing design in the context of sustainability and digital transformation, emphasizing its significance in manufacturing capabilities worldwide.

Innovative Bearing Technologies Showcased at the Fair

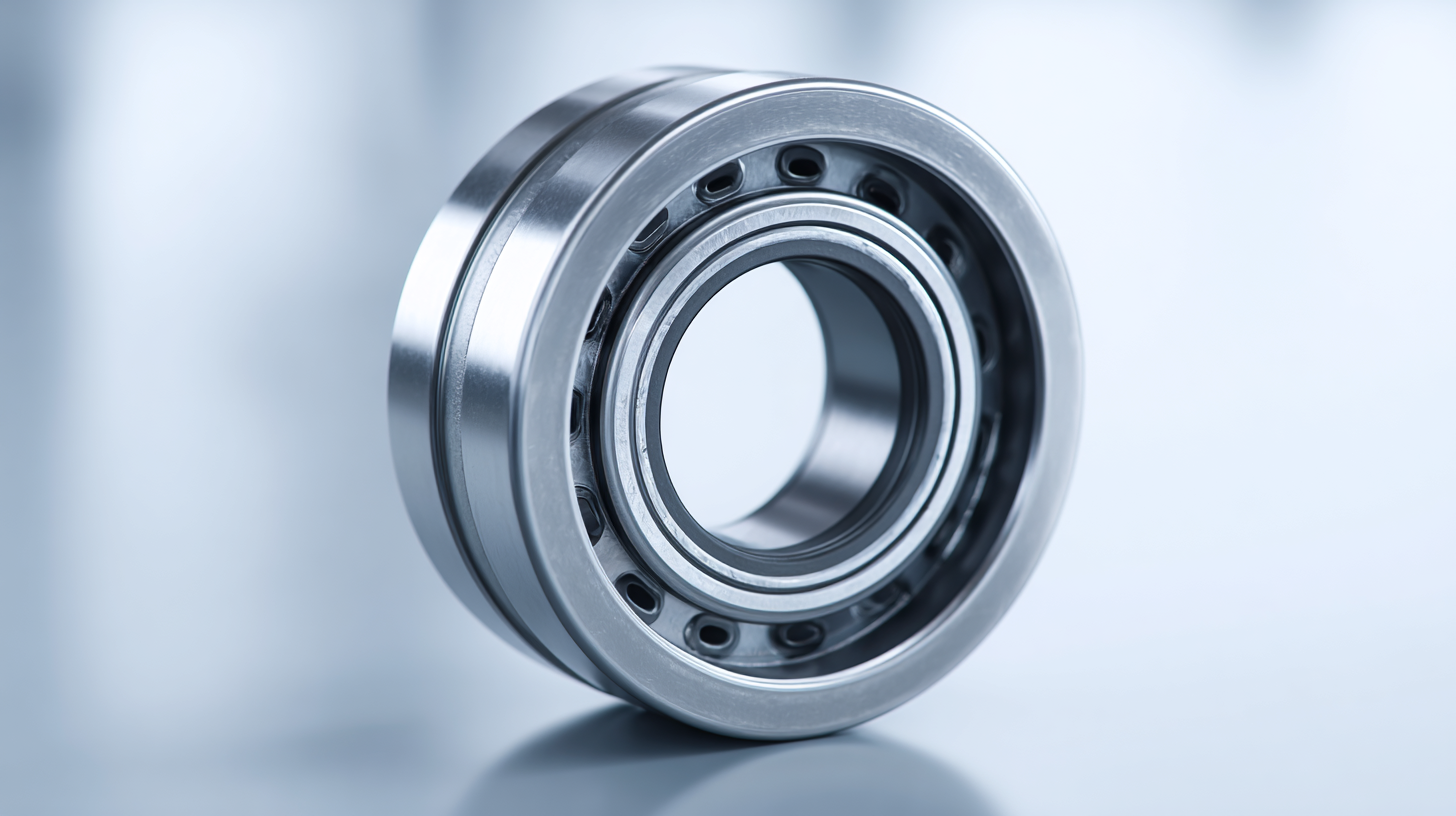

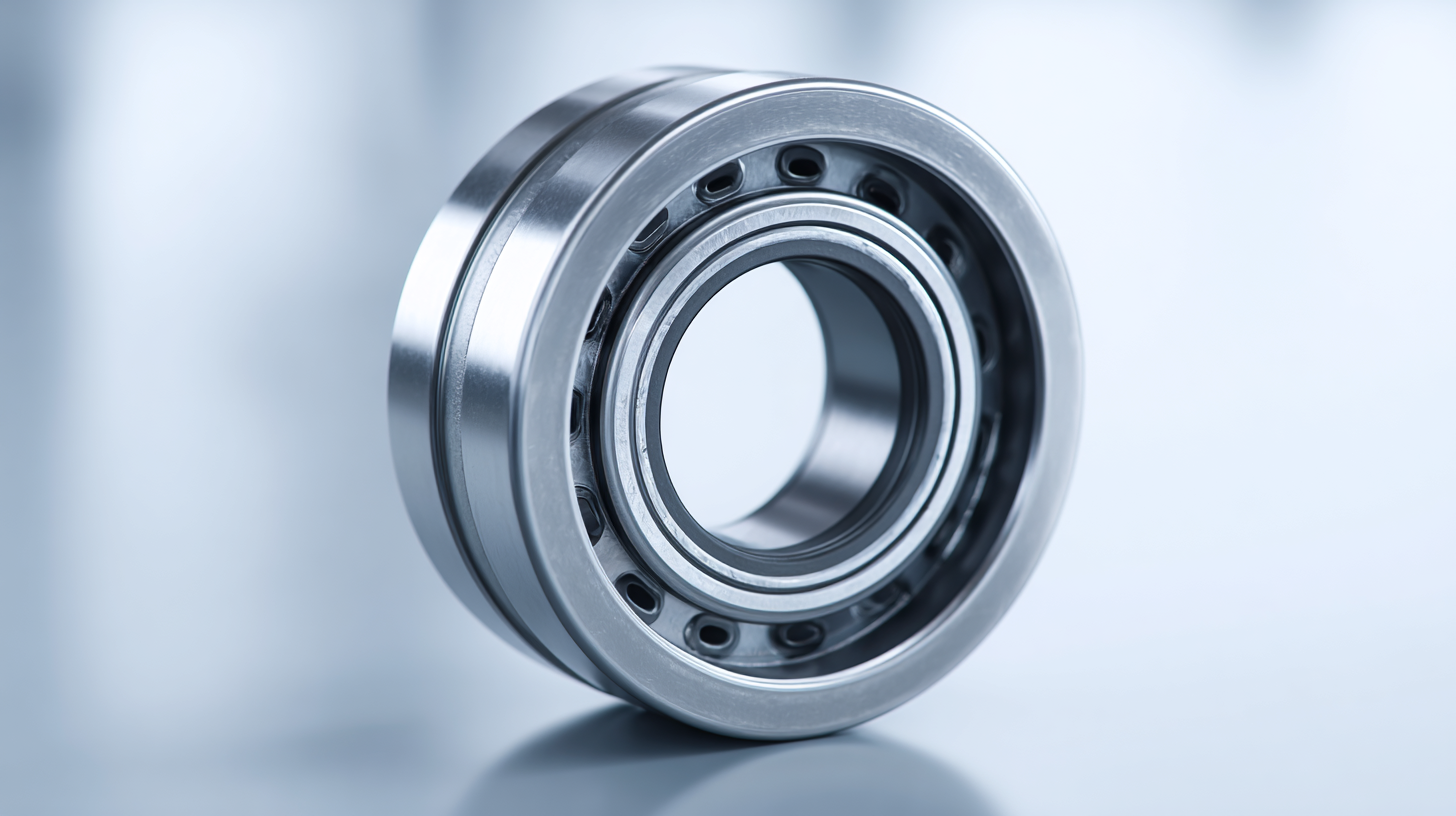

The 138th China Import and Export Fair in 2025 is set to be a showcase of cutting-edge innovations in bearing technology, reflecting the industry's ongoing commitment to enhancing performance and efficiency. Exhibitors from around the globe will present their latest advancements, ranging from high-capacity bearings designed for heavy machinery to miniature bearings tailored for precision instruments. These innovations are aimed at reducing friction, improving load capacity, and extending service life, thereby meeting the evolving demands of various sectors.

Among the prominent technologies to be featured are smart bearings equipped with IoT capabilities, allowing for real-time monitoring and predictive maintenance. This integration of technology not only enhances operational efficiency but also reduces downtime, leading to significant cost savings for manufacturers. Additionally, the fair will highlight the use of advanced materials in bearing design, such as composite and ceramic materials, which offer improved durability and resistance to extreme environments. This convergence of technology and materials science signifies a pivotal shift in bearing design, setting new standards for performance across multiple industries.

Key Players in the Bearing Industry Presenting New Designs

At the 138th China Import and Export Fair in 2025, key players in the bearing industry are set to unveil groundbreaking designs that promise to enhance performance and reliability. Leading manufacturers are showcasing innovations that cater to emerging market needs, such as energy efficiency and sustainability. These designs not only address the demands of modern machinery but also align with global trends toward reducing environmental impact.

Tips for attendees include exploring the various materials being used in new bearing designs, such as advanced polymers and composite materials, which can offer significant weight reductions and increased load capacities. Networking with industry leaders can provide insights into future trends and compatibility issues, crucial for making informed purchasing decisions.

Another valuable tip is to attend workshops and presentations that focus on the latest technologies, such as smart bearings equipped with IoT capabilities. These innovations allow for real-time performance monitoring, drastically reducing maintenance costs and improving operational efficiency. Engaging with exhibitors will provide a deeper understanding of how these advancements can be integrated into current systems.

Sustainability and Eco-Friendly Innovations in Bearing Manufacturing

At the upcoming 138th China Import and Export Fair in 2025, the spotlight will be on sustainability and eco-friendly innovations in bearing manufacturing. As industries globally prioritize environmental responsibility, advancements in materials and production methods are pivotal. Recent developments showcase how companies are shifting away from traditional materials towards greener alternatives, addressing the pressing need for more sustainable practices in manufacturing processes. The use of recycled materials, such as glass, not only enhances material performance but also improves soil properties, contributing to a circular economy.

Moreover, innovations in bearing design are moving towards decarbonization, with prototypes demonstrating the potential of green steel in reducing the carbon footprint of products. This commitment to sustainability echoes in the broader manufacturing landscape, where the integration of sustainable technologies is becoming essential. As consumers increasingly consider eco-friendliness in their purchasing decisions, manufacturers must adapt, investing in research and development that aligns with these values while enhancing durability and efficiency in bearing applications. The fair will serve as a platform to highlight these advancements and inspire further dialogue on sustainable practices within the industry.

Impact of Advanced Materials on Bearing Performance and Longevity

At the 138th China Import and Export Fair in 2025, innovations in bearing design are poised to revolutionize the industry. Advanced materials such as carbon fiber, ceramics, and composites are playing a crucial role in enhancing bearing performance and longevity. These materials not only reduce the weight of bearings but also significantly improve their resistance to wear and corrosion. As industries demand more from their operational components, the utilization of advanced materials becomes essential in engineering bearings that can withstand extreme conditions.

Tips: When selecting bearings for specific applications, consider the environmental factors they will be exposed to, such as temperature and humidity. Choosing the right material can drastically extend the lifespan of the bearings and reduce maintenance costs.

Furthermore, the integration of technologies like 3D printing is enabling manufacturers to create complex geometries that were previously impossible. This innovation not only allows for tailored designs that fit specific applications perfectly but also contributes to reduced manufacturing waste. With these advancements, companies are not only improving efficiency but also embracing sustainability in their operations.

Tips: Always stay updated on the latest advancements in bearing materials and manufacturing technologies. This knowledge can provide a competitive edge, allowing for better product selections that align with the latest performance standards.

Innovations in Bearing Design at the 138th China Import and Export Fair 2025

This chart illustrates the impact of advanced materials on bearing performance and longevity. The data reflects the performance metrics of various bearing materials tested for fatigue resistance, temperature tolerance, and overall lifespan.

Future Trends in Bearing Design Highlighted at the Event

At the 138th China Import and Export Fair in 2025, innovations in bearing design took center stage, showcasing the evolution of technology and engineering practices within this crucial industry. The event highlighted the latest advancements in bearing components, materials, and manufacturing processes, reflecting a shift towards more sustainable and efficient solutions. Exhibitors presented lightweight materials, such as composites and advanced alloys, which not only enhance performance but also contribute to energy savings in various applications.

Future trends discussed at the fair emphasized digital integration and smart technology. The adoption of IoT-enabled bearings is revolutionizing how industries approach maintenance and performance monitoring. Predictive analytics and real-time data collection can lead to significant improvements in reliability and longevity, reducing downtime and maintenance costs. Attendees were particularly excited about the potential for automation and AI-driven design processes, forecasting a promising future for bearing applications across multiple sectors, from automotive to aerospace, underlining the sector's commitment to innovation and efficiency.

Innovations in Bearing Design at the 138th China Import and Export Fair 2025

| Innovation Type |

Description |

Potential Applications |

Expected Impact |

| Smart Bearings |

Integration of IoT sensors for real-time monitoring. |

Manufacturing, aviation, and automotive industries. |

Enhanced reliability and predictive maintenance. |

| Bio-based Lubricants |

Use of eco-friendly materials for lubrication. |

Compostable machines and sustainable industry practices. |

Reduced environmental impact and sustainability. |

| Advanced Material Use |

Utilization of composites and nanomaterials for durability. |

Heavy machinery, aerospace applications. |

Increased lifespan and reduced maintenance costs. |

| Self-Aligning Bearings |

Design improvements for better alignment and load distribution. |

Wind turbines, conveyor systems. |

Improved efficiency and reduced wear. |

| Smart Manufacturing Integration |

Adoption of AI and automation in bearing manufacturing. |

All sectors utilizing bearings. |

Higher production efficiency and less waste. |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

As the global manufacturing landscape evolves, innovations in bearing design play a crucial role in enhancing machinery performance and sustainability. At the 138th China Import and Export Fair in 2025, industry leaders will showcase cutting-edge advancements that address the growing demand for efficient and durable bearings. According to a recent market analysis by Research and Markets, the global bearing market is projected to reach approximately $135 billion by 2025, driven by increasing applications in automotive, aerospace, and industrial machinery.

As the global manufacturing landscape evolves, innovations in bearing design play a crucial role in enhancing machinery performance and sustainability. At the 138th China Import and Export Fair in 2025, industry leaders will showcase cutting-edge advancements that address the growing demand for efficient and durable bearings. According to a recent market analysis by Research and Markets, the global bearing market is projected to reach approximately $135 billion by 2025, driven by increasing applications in automotive, aerospace, and industrial machinery.