Innovative Automotive Bearings Types and Their Applications in Modern Vehicles

In the rapidly evolving world of modern vehicles, the significance of automotive bearings cannot be overstated. These critical components play a fundamental role in ensuring smooth operation and enhancing the overall performance of vehicles, from efficiency to longevity. As technology advances, the types of automotive bearings have also diversified, introducing innovative designs that cater to the specific demands of contemporary automotive engineering. This blog will explore the latest trends in automotive bearing types, examining their unique applications and the ways they contribute to improving vehicle performance. From specialized materials to cutting-edge manufacturing techniques, understanding these innovations is essential for anyone interested in the future of automotive design and functionality. Join us as we delve into the top strategies for leveraging automotive bearings in modern vehicles, highlighting their indispensable role in driving the industry forward.

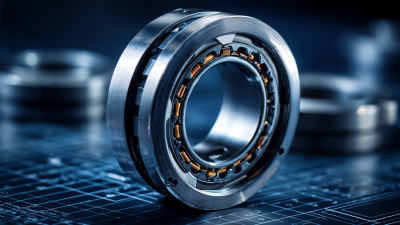

Comparison of Rolling Bearings and Sliding Bearings in Automotive Applications

In the automotive industry, the choice between rolling bearings and sliding bearings plays a critical role in enhancing performance and efficiency.

Rolling bearings, particularly microtextured varieties, have emerged as innovative solutions aimed at reducing friction and power losses.

Research indicates that incorporating microdimple-textured surfaces into rolling bearings can significantly improve lubrication conditions, potentially extending the lifespan of components and minimizing energy consumption.

For instance, studies have shown a noteworthy reduction in friction power losses, highlighting a desirable feature that supports fuel efficiency in modern vehicles.

In the automotive industry, the choice between rolling bearings and sliding bearings plays a critical role in enhancing performance and efficiency.

Rolling bearings, particularly microtextured varieties, have emerged as innovative solutions aimed at reducing friction and power losses.

Research indicates that incorporating microdimple-textured surfaces into rolling bearings can significantly improve lubrication conditions, potentially extending the lifespan of components and minimizing energy consumption.

For instance, studies have shown a noteworthy reduction in friction power losses, highlighting a desirable feature that supports fuel efficiency in modern vehicles.

On the other hand, sliding bearings continue to hold their ground in engineering applications due to their simple design and ability to handle significant loads.

However, they are not without challenges; friction and wear are common issues that can lead to increased maintenance costs.

Investing in advanced materials and optimized designs can help manufacturers mitigate these problems, ensuring that sliding bearings remain a viable choice in specific automotive applications.

Tips:

When selecting between rolling and sliding bearings, consider factors such as operating conditions, load capacity, and desired efficiency.

Regular condition monitoring can also enhance the lifespan of both bearing types, making it essential for optimal vehicle performance.

Exploring the Advantages of Ball Bearings vs. Roller Bearings in Vehicle Performance

In the evolving landscape of modern vehicles, the choice between ball bearings and roller bearings plays a crucial role in enhancing vehicle performance. Ball bearings are renowned for their ability to reduce friction, owing to ceramic bearing balls that require less lubrication and generate less wear. This characteristic is particularly beneficial in electric and hybrid vehicles, where advancements are driving down the need for maintenance while improving efficiency. The global automotive bearing market, valued at approximately USD 14.76 billion in 2023, reflects a steady growth trajectory, with projections indicating an increase to USD 21.38 billion by 2032, indicating a rising demand for innovative bearing solutions.

On the other hand, roller bearings are gaining prominence, especially in heavy-duty applications due to their high-load carrying capacity. The global roller bearings market has shown significant growth, valued at USD 21.05 billion in 2018 and expected to reach USD 32.45 billion by the end of 2032. This surge highlights the increasing importance of reliable and robust bearings in the automotive sector, particularly as manufacturers incorporate advanced technologies into new vehicle designs. The latest innovations, tailored for electric vehicles, focus on optimizing performance and longevity, making both ball and roller bearings essential components in the quest for improved vehicle efficiency and reliability.

Ceramic Bearings vs. Steel Bearings: Which is Better for Modern Automotive Needs?

The debate between ceramic bearings and steel bearings continues to evolve as modern vehicles push the boundaries of performance and efficiency. Ceramic bearings offer significant advantages, such as reduced weight and lower rolling resistance, making them ideal for high-performance applications. The ability of ceramic materials to withstand higher temperatures also contributes to their growing popularity among automobile manufacturers looking to enhance durability and extend service life. This shift is particularly relevant in markets where weight savings can lead to improved fuel efficiency.

On the other hand, steel bearings have a proven track record in broader automotive applications due to their cost-effectiveness and mechanical robustness. They are widely used in everyday vehicles and remain a reliable option for standard applications. The global automotive bearing market is projected to continue its growth, highlighting the importance of both types in meeting diverse automotive needs. As technologies advance, the decision between ceramic and steel bearings will ultimately depend on specific application requirements, balancing performance with cost considerations in the ever-evolving landscape of modern vehicles.

Comparative Analysis of Standard Bearings and Pre-Lubricated Bearings in Efficiency

When it comes to automotive bearings, efficiency plays a crucial role in enhancing vehicle performance. This blog focuses on the comparative analysis of standard bearings and pre-lubricated bearings. Standard bearings, while widely used, require consistent maintenance and lubrication to function optimally. They often lead to increased friction, which can affect fuel efficiency and overall vehicle longevity. In contrast, pre-lubricated bearings come with lubrication already applied, resulting in reduced friction from the outset and providing a more reliable performance over time. This makes them an attractive option for modern vehicles where efficiency is paramount.

Tip: When selecting bearings for your vehicle, consider the long-term maintenance implications of standard versus pre-lubricated options. Pre-lubricated bearings may have a higher initial cost, but their reduced maintenance requirement can lead to savings in the long run.

Understanding the impact of bearing choices on efficiency is essential for both manufacturers and consumers. Implementing pre-lubricated bearings can lead to improved fuel economy and reduced emissions, aligning with the automotive industry's push towards sustainability.

Tip: Always consult with a trusted mechanic or bearing specialist to estimate the best bearing type for your specific application, ensuring you optimize your vehicle's performance while minimizing potential downtimes.

Evaluating the Impact of Advanced Composite Bearings on Vehicle Weight and Fuel Efficiency

Advanced composite bearings are revolutionizing the automotive industry by significantly impacting vehicle weight and fuel efficiency. According to a report by the American Institute of Physics, these bearings are up to 30% lighter than traditional steel options, which can lead to a reduction in the overall vehicle mass. A decrease in weight is directly linked to improved fuel efficiency; for every 10% reduction in vehicle weight, fuel consumption can decrease by approximately 6-8%. This correlation highlights the crucial role that advanced composite bearings play in modern vehicle design.

Moreover, studies indicate that the use of advanced composite materials in bearings not only reduces weight but also enhances performance and durability. For instance, a report from the Society of Automotive Engineers notes that composite bearings can withstand higher load capacities and have better resistance to wear, contributing to longer service intervals and lower maintenance costs. This dual benefit of weight reduction and performance improvement positions advanced composite bearings as a key component in the pursuit of sustainable automotive engineering, ultimately leading to more efficient and eco-friendly vehicles on the road.

Impact of Advanced Composite Bearings on Vehicle Weight and Fuel Efficiency

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

In the automotive industry, the choice between rolling bearings and sliding bearings plays a critical role in enhancing performance and efficiency.

In the automotive industry, the choice between rolling bearings and sliding bearings plays a critical role in enhancing performance and efficiency.