How to Maintain Rotating Bearings for Optimal Performance?

Maintaining rotating bearings is crucial for optimal machinery performance. According to a recent report from the American Society of Mechanical Engineers, poor bearing maintenance can lead to a 30% reduction in operational efficiency. Rotating bearings are essential components in various industries, including manufacturing, automotive, and aerospace. Yet, many organizations overlook their maintenance, resulting in costly downtimes.

Regular inspections and proper lubrication can extend the lifespan of rotating bearings. Data from the Bearing Specialists Association indicates that approximately 50% of bearing failures stem from inadequate lubrication. This highlights the need for a strategic approach to maintenance. Even small lapses can lead to significant issues, such as overheating or premature wear.

Understanding the specific requirements of rotating bearings is vital. Some bearings may require specialized lubricants or monitoring systems to ensure optimal performance. Failure to adapt maintenance strategies can hinder overall machinery effectiveness. Only by addressing these complexities can industries maximize the reliability and efficiency of their rotating bearings.

Understanding the Basics of Rotating Bearings and Their Applications

Rotating bearings are essential components in various machines. They enable smooth movement between parts, minimizing friction. Their applications span from automotive engines to industrial machinery. Understanding how they work is crucial for optimal performance. When choosing a bearing, consider load capacity, speed, and environment. Each factor plays a role in how long the bearing lasts.

Lubrication is key for bearings. Insufficient lubrication leads to failure. Regular maintenance checks are important. It's easy to overlook. Inspect for signs of wear or discoloration. Clean the bearings periodically to remove contaminants. Some maintenance practices often don't provide immediate feedback. They may seem unnecessary until a failure occurs.

Temperature control also impacts bearing performance. High temperatures can lead to premature wear. Monitoring operating conditions can prevent issues. It's often challenging to maintain the perfect balance. Operators might ignore small fluctuations in temperature, assuming they are not critical. However, consistent monitoring can enhance bearing lifespan significantly. Every detail matters in the long run.

Identifying Common Issues in Rotating Bearings and Their Impact on Performance

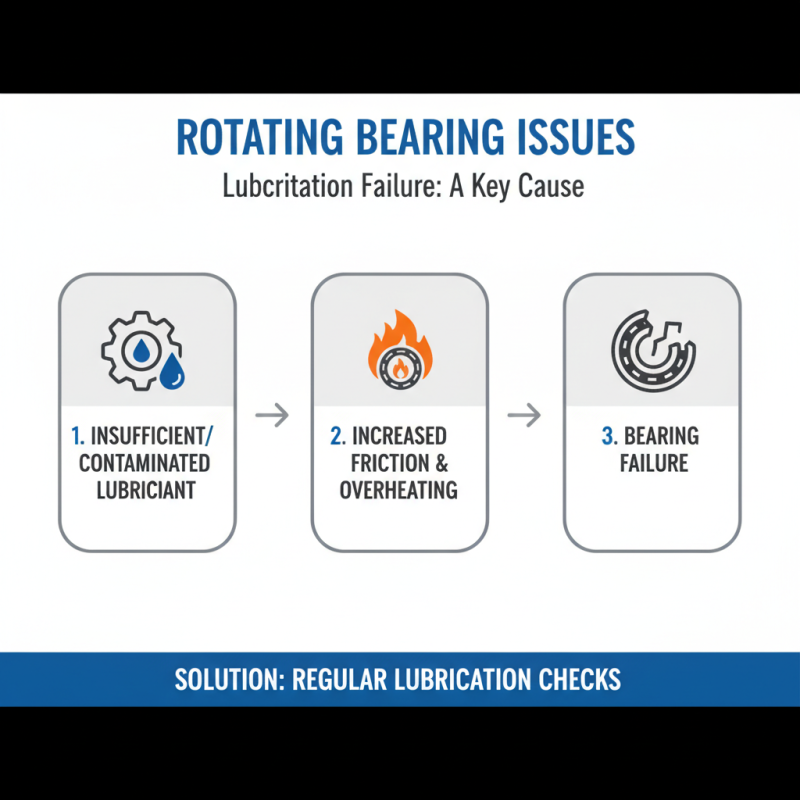

Rotating bearings are critical components in many machines. They support loads while enabling smooth motion. However, common issues can lead to decreased performance. One such issue is lubrication failure. Insufficient or contaminated lubricant can cause friction, leading to overheating. This can ultimately result in bearing failure. Regular checks on lubrication levels and quality are essential.

Another frequent problem is misalignment. When the shaft and bearing are not aligned correctly, it leads to uneven wear. This may create vibrations, causing further complications. Implementing alignment tools and periodic inspections can help mitigate this risk. Additionally, contamination from dirt or debris can severely impact how bearings function. Seals are important, yet they sometimes fail, allowing contaminants to enter.

Proper monitoring can identify these problems early. It's crucial to reflect on maintenance routines and identify areas for improvement. Regular training for operators on bearing care can prevent serious issues down the line. Being proactive keeps machinery running efficiently and avoids costly shutdowns.

Establishing a Regular Maintenance Schedule for Rotating Bearings

Establishing a regular maintenance schedule for rotating bearings is crucial for optimal performance. Data from the International Journal of Engineering Research indicates that improper maintenance can lead to a 30% reduction in bearing lifespan. Regular inspections can reveal early signs of wear, such as discoloration or abnormal noise. These indicators often get overlooked in busy operations.

Frequent lubrication also plays a vital role. Research shows that bearings maintained with proper lubrication can last up to 60% longer than those with inconsistent schedules. Implementing a routine, like weekly checks, keeps bearings in check. It’s essential to adjust lubrication intervals based on usage and environmental conditions.

However, developing an effective schedule isn't always straightforward. Many operations struggle with timing their maintenance properly. Oversights occur, especially in high-demand environments. Regular audits can help identify missed maintenance tasks. Periodic reviews of the maintenance schedule can enhance both the quality and reliability of operations. It's a cycle of continuous improvement that requires dedication.

How to Maintain Rotating Bearings for Optimal Performance?

| Maintenance Task |

Frequency |

Recommended Tools |

Notes |

| Visual Inspection |

Weekly |

Inspection Mirror, Flashlight |

Check for signs of wear and rust. |

| Lubrication |

Monthly |

Grease Gun, Lubricant |

Use the manufacturer's recommended lubricant. |

| Vibration Analysis |

Quarterly |

Vibration Meter |

Identify any abnormal vibrations. |

| Temperature Monitoring |

Monthly |

Infrared Thermometer |

Ensure operating temperature is within safe limits. |

| Bearing Replacement |

As Needed |

Puller, Wrench Set |

Replace if excessive wear is detected. |

Techniques for Proper Lubrication and Cleaning of Rotating Bearings

Maintaining rotating bearings is essential for optimal performance. Proper lubrication and cleaning play crucial roles in their longevity. It’s vital to select the right lubricant for the specific application. A high-viscosity grease may not be suitable for all environments. For example, heavy-duty applications may require a thicker lubricant, while lighter systems benefit from a thinner one.

Regular cleaning is equally important. Dirt and debris can compromise the integrity of bearings. Use a soft brush or cloth to remove any visible contaminants. Pay attention to the seals, as they are often where dirt gathers. Sometimes, a thorough wash with a suitable solvent is needed. However, be cautious: excessive cleaning can wear down the seals themselves.

**Tip:** Always check the manufacturer's specifications for lubrication intervals. Over-lubrication can cause overheating.

**Tip:** Inspect bearings frequently. Listen for unusual noises; they may signal issues. Early detection can save costs later.

Bearings require a balance of care and attention. Strive for maintenance routines that address both lubrication and cleaning without overdoing either. It's about finding the middle ground for efficiency.

Monitoring and Analyzing Performance Metrics for Rotating Bearings

Monitoring the performance of rotating bearings is crucial for their efficiency. Start by tracking temperature variations. High temperatures can signal friction issues or insufficient lubrication. Use infrared thermometers or thermocouples for accurate readings. Regular inspections should include checking for any vibration anomalies. Excessive vibration often points to misalignment or wear.

Another key metric to watch is noise. Listen for unusual sounds during operation. This can help identify potential problems before they escalate. Analyzing lubrication quality is equally important. Contaminated oil or grease can lead to premature failure. Implementing a routine oil analysis can reveal vital information about the lubricant's condition.

Finally, keep records of all performance metrics. It’s essential for identifying trends over time. Compare current data with historical performance. This reflection can highlight areas needing improvement. Regular assessments can prevent larger issues, ensuring optimal operation of rotating bearings.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us