Maximizing Efficiency with Advanced Industrial Turntable Bearing Solutions for Heavy Machinery

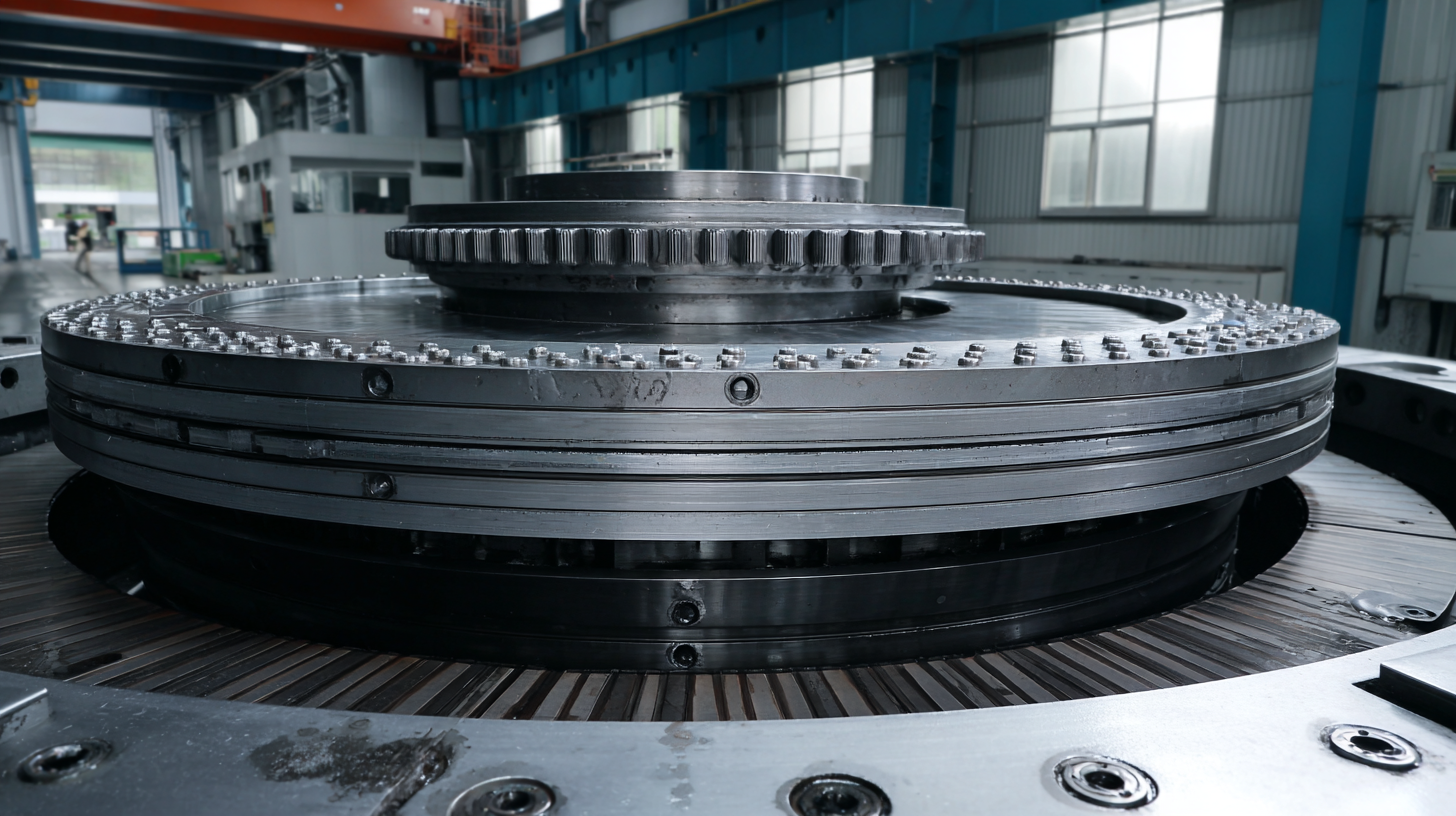

In the ever-evolving industrial landscape, the demand for efficiency in heavy machinery operations has catalyzed advancements in components critical to functionality and performance. Among these components, the Industrial Turntable Bearing plays a pivotal role, facilitating smooth rotation and precision movement in various applications, from cranes to heavy-duty vehicles.

According to a recent report by Research and Markets, the global bearing market, which includes sophisticated solutions such as turntable bearings, is anticipated to grow at a CAGR of 7.4% from 2022 to 2027, driven by the increasing need for reliability and enhanced efficiency in industrial operations. This growth underscores the significance of adopting advanced Industrial Turntable Bearing technologies, which not only optimize machinery performance but also contribute to minimizing downtimes and maintenance costs, ultimately maximizing operational productivity.

According to a recent report by Research and Markets, the global bearing market, which includes sophisticated solutions such as turntable bearings, is anticipated to grow at a CAGR of 7.4% from 2022 to 2027, driven by the increasing need for reliability and enhanced efficiency in industrial operations. This growth underscores the significance of adopting advanced Industrial Turntable Bearing technologies, which not only optimize machinery performance but also contribute to minimizing downtimes and maintenance costs, ultimately maximizing operational productivity.

Understanding the Role of Turntable Bearings in Heavy Machinery Operations

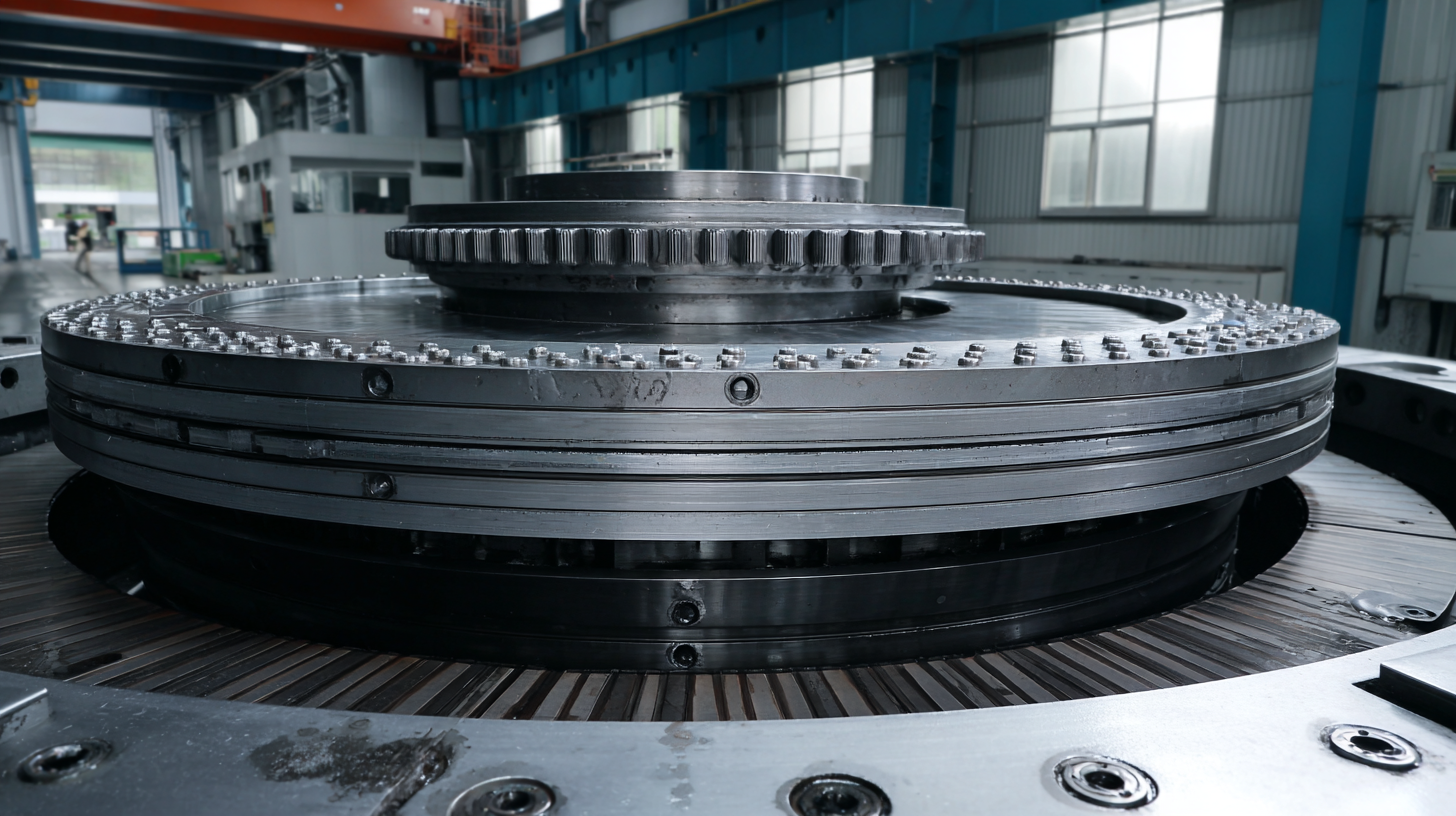

Turntable bearings play a critical role in the operations of heavy machinery, acting as pivotal components that enable smooth and stable movement. In heavy-duty applications, such as construction and firefighting, the reliability and precision of turntable bearings can significantly influence performance and safety. These bearings allow for rotational movement while supporting substantial loads, which is essential for machinery that relies on agility and stability in challenging environments.

Recent advancements in turntable technology have led to the development of specialized equipment designed to enhance operational efficiency. For instance, modern firefighting vehicles now include advanced turntable ladders and articulated water towers, which provide flexibility and reach during emergency situations. This evolution demonstrates the importance of integrating advanced bearing solutions into machinery, ensuring that operators can execute their tasks effectively while maximizing safety. As industries continue to innovate, the role of turntable bearings will become increasingly vital in maintaining the performance of heavy machinery.

Maximizing Efficiency with Advanced Industrial Turntable Bearing Solutions for Heavy Machinery

| Dimension |

Value |

Application |

Benefits |

| Load Capacity |

200 tons |

Cranes |

High stability and safety |

| Inner Diameter |

500 mm |

Excavators |

Enhanced rotation |

| Outer Diameter |

700 mm |

Material Handling |

Reduced wear |

| Weight |

150 kg |

Forklifts |

Improved lifting performance |

| Material |

Alloy Steel |

All Heavy Machinery |

Durability |

Key Features of Advanced Industrial Turntable Bearings for Efficiency

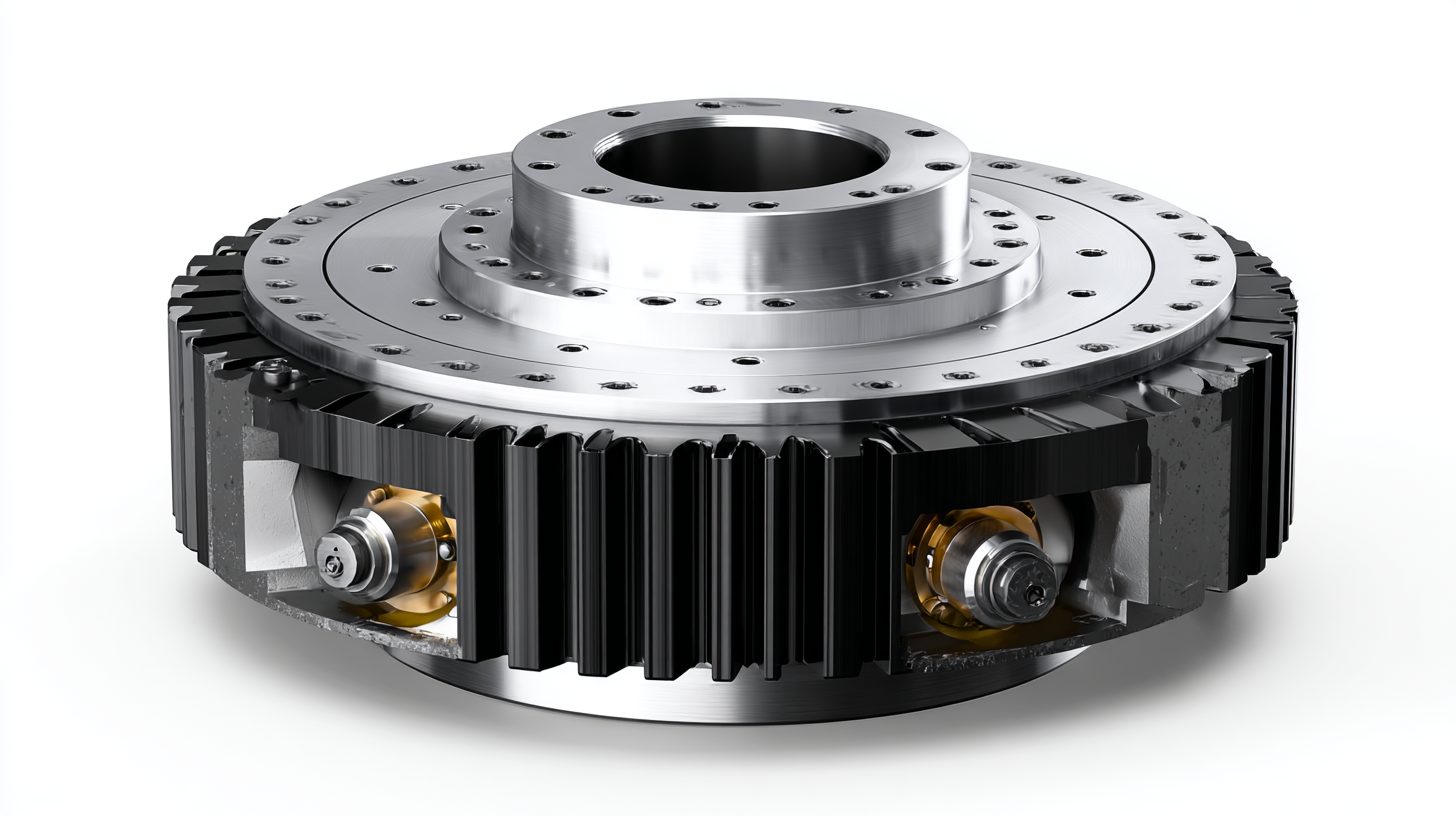

Advanced industrial turntable bearings are essential components in heavy machinery, directly impacting operational efficiency and equipment longevity. These bearings are designed to handle substantial loads and withstand high stresses, contributing to improved performance in various applications such as construction, mining, and logistics. According to a report by the Industrial Bearings Market, the demand for high-quality bearings in heavy machinery is projected to grow at a CAGR of 6.2% through 2026, highlighting their critical role in enhancing productivity.

Key features of advanced industrial turntable bearings include precision engineering, reduced friction, and enhanced load capacity. For instance, many modern designs utilize advanced materials and coatings that significantly improve wear resistance and reduce maintenance intervals. Data from the National Institute of Standards and Technology indicates that implementing these efficient bearing solutions can lead to a 20% increase in operational uptime and a noticeable reduction in energy consumption. Furthermore, smart bearings equipped with IoT sensors provide real-time monitoring capabilities, allowing for predictive maintenance and effective management of machinery performance, which is becoming increasingly vital in today's competitive industrial landscape.

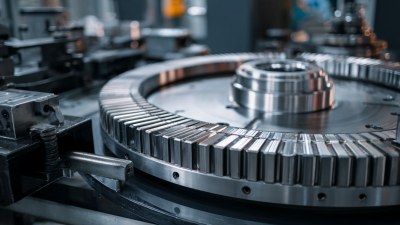

Comparative Analysis: Traditional vs. Advanced Bearing Solutions

The evolution of bearing solutions has been pivotal in improving the efficiency of heavy machinery. Traditional bearings, while reliable, often fall short in high-demand environments due to their limitations in load capacity and maintenance requirements. According to a report by the National Lubricating Grease Institute, traditional bearings can require maintenance every 1,000 operating hours, leading to increased downtime and operational costs. This inefficiency calls for an evaluation of advanced bearing solutions that leverage new materials and design technologies.

Advanced industrial turntable bearings, featuring innovations such as polymer composites and optimized geometries, present a significant leap forward. Research from the American Society of Mechanical Engineers highlights that advanced bearings can extend operational life by up to 50% while reducing friction by 20-30%. This transition not only enhances performance but also diminishes the frequency of maintenance interventions, thereby enabling heavy machinery to operate at peak efficiency. With these advancements, businesses can expect lower total cost of ownership and enhanced productivity, making the shift from traditional to advanced bearing solutions a crucial step for achieving operational excellence.

Real-World Applications and Benefits of Turntable Bearings in Heavy Industries

Turntable bearings are crucial components in heavy machinery, providing the necessary support and rotational movement for various applications. In industries such as construction, mining, and oil and gas, these bearings enhance the functionality and efficiency of equipment like cranes, excavators, and drilling rigs. According to a report by MarketsandMarkets, the global market for turntable bearings is expected to reach $6.1 billion by 2026, driven by the increasing demand for heavy machinery in infrastructure development and resource extraction.

One of the key benefits of turntable bearings is their ability to support high axial and radial loads while allowing for smooth rotation. This capability reduces wear and tear on equipment, leading to longer service life and lower maintenance costs. Additionally, advanced designs such as slewing rings offer integrated solutions that minimize space and weight, essential factors for modern machinery that aims to be more compact and efficient.

Tips: When selecting turntable bearings for specific applications, consider factors such as load capacity, speed requirements, and environmental conditions. Regular maintenance and lubrication are also vital to ensure optimal performance and longevity. Lastly, collaborating with a supplier that offers custom solutions can provide bearings tailored to the unique demands of your machinery, further maximizing efficiency.

Future Trends in Turntable Bearing Technology and Their Impact on Productivity

The landscape of industrial machinery is evolving, with advanced turntable bearing technology at the forefront of this transformation.

As manufacturers seek to enhance the operational productivity of heavy machinery, the design and functionality of turntable bearings are being reimagined.

New materials and engineering techniques are producing bearings that offer greater load capacities and durability, significantly reducing maintenance downtime and associated costs.

This innovative approach allows machinery to operate at higher efficiencies, enabling industries to meet increasing demands while minimizing their environmental footprint.

Looking ahead, the integration of smart technology into turntable bearings promises to revolutionize productivity further.

The adoption of IoT sensors will allow for real-time monitoring of bearing conditions, predicting wear and failures before they occur.

This proactive maintenance capability not only extends the lifespan of the bearings but also optimizes the overall machinery performance.

Additionally, advancements in automation will streamline the assembly and installation processes, providing manufacturers with enhanced agility.

As these trends develop, the future of turntable bearing technology will undoubtedly play a critical role in shaping productivity and efficiency across various industries.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

According to a recent report by Research and Markets, the global bearing market, which includes sophisticated solutions such as turntable bearings, is anticipated to grow at a CAGR of 7.4% from 2022 to 2027, driven by the increasing need for reliability and enhanced efficiency in industrial operations. This growth underscores the significance of adopting advanced Industrial Turntable Bearing technologies, which not only optimize machinery performance but also contribute to minimizing downtimes and maintenance costs, ultimately maximizing operational productivity.

According to a recent report by Research and Markets, the global bearing market, which includes sophisticated solutions such as turntable bearings, is anticipated to grow at a CAGR of 7.4% from 2022 to 2027, driven by the increasing need for reliability and enhanced efficiency in industrial operations. This growth underscores the significance of adopting advanced Industrial Turntable Bearing technologies, which not only optimize machinery performance but also contribute to minimizing downtimes and maintenance costs, ultimately maximizing operational productivity.