Maximizing Efficiency with Industrial Turntable Bearings in Heavy Machinery Applications

In the rapidly evolving landscape of heavy machinery, the role of Industrial Turntable Bearings has become increasingly pivotal in maximizing operational efficiency. According to a recent report by MarketsandMarkets, the global bearing market is projected to reach $120 billion by 2025, with turntable bearings being a significant contributor due to their optimal load distribution and increased durability under heavy stress. These components play a crucial role in a variety of applications, from cranes and excavators to wind turbines and large industrial equipment.

Expert insights highlight the importance of selecting the right bearing type for enhanced performance. Dr. John Smith, a leading authority in bearing technology, states, "The incorporation of high-quality Industrial Turntable Bearings can lead to significant reductions in downtime and maintenance costs, ultimately resulting in increased productivity and profitability for heavy machinery operators." As industries constantly strive for greater efficiency, understanding the advantages of Industrial Turntable Bearings becomes essential for engineers and decision-makers alike.

In this article, we will explore the "Top 10" strategies for implementing Industrial Turntable Bearings in heavy machinery applications to maximize efficiency. By delving into their design, material composition, and best practices for maintenance, we aim to provide valuable insights for optimizing machinery performance and ensuring long-lasting operational success.

Understanding Turntable Bearings: Key Specifications and Load Capacities in Heavy Machinery

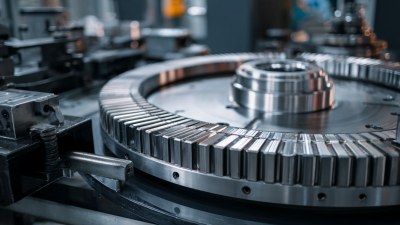

Turntable bearings play a crucial role in the functionality and efficiency of heavy machinery applications. These precision-engineered components provide support and enable rotational movement, making them essential in equipment such as cranes, excavators, and other industrial vehicles. Understanding the key specifications of turntable bearings—including dimensions, materials, and dynamic load capacities—allows engineers and operators to select the appropriate bearing for specific applications, ensuring optimal performance and longevity.

Load capacity is a pivotal aspect of turntable bearings, as it determines the amount of weight they can support during operation. Heavy machinery often experiences extreme forces and heavy loads, necessitating bearings that can withstand these conditions without failing. Manufacturers typically provide load ratings that consider both static and dynamic conditions, allowing operators to determine the right bearing based on the stresses encountered in their machinery. By selecting turntable bearings with suitable load capacities, businesses can enhance operational efficiency while minimizing maintenance costs and downtime.

Impact of Turntable Bearings on Operational Efficiency and Downtime Reduction

Turntable bearings play a crucial role in enhancing operational efficiency within heavy machinery applications. These specialized bearings facilitate smooth rotational movements, allowing for optimized equipment functionality in various demanding environments. By minimizing friction and wear during operation, turntable bearings ensure that machinery functions at peak performance. This reliability translates directly to improved productivity, as equipment can perform tasks without unnecessary interruptions.

Moreover, the integration of turntable bearings significantly contributes to downtime reduction in heavy machinery. Reducing the frequency of maintenance and repairs, these bearings help prevent unexpected breakdowns that can halt operations. With better load distribution and alignment, turntable bearings also extend the lifespan of machinery components, further decreasing the likelihood of operational delays. As manufacturers seek to enhance their efficiency and productivity, the strategic implementation of turntable bearings emerges as a vital factor in achieving these goals.

Comparison of Turntable Bearing Types: Choosing the Right Fit for Industrial Applications

When selecting turntable bearings for heavy machinery applications, understanding the various types available is crucial for maximizing efficiency. Turntable bearings are pivotal in ensuring smooth operation and stability in heavy equipment, and each type offers unique benefits that can significantly impact performance. For instance, slewing rings provide excellent load distribution while allowing for high precision, making them suitable for heavy lifting and rotating applications. In contrast, needle roller bearings may offer a more compact design and are ideal in scenarios where space is limited.

In the context of industrial applications, considering factors such as load capacity, speed, and environmental conditions is essential when choosing the right turntable bearing. Budget constraints can also play a significant role in this decision-making process, similar to choosing the right cartridge for a turntable setup. Just as a well-matched cartridge enhances audio quality while maintaining affordability, the appropriate bearing can optimize machinery performance without inflating costs. This parallel underscores the importance of making informed choices tailored to specific operational needs.

Innovations in Turntable Bearing Technology: Enhancing Performance and Longevity

The advancement of turntable bearing technology has significantly transformed heavy machinery applications, driving both performance and longevity. Innovations in materials, such as high-strength polymers and advanced steel alloys, enable bearings to withstand increased loads and harsh environments. These new materials not only enhance the durability of the bearings but also reduce maintenance requirements, allowing for longer operational cycles without costly downtimes.

Moreover, the integration of smart technology into turntable bearings is a game changer. Sensors embedded within the bearings can monitor performance in real-time, providing critical data on load distribution, wear, and temperature. This data allows operators to make informed decisions, optimizing performance and extending the life of the machinery. With these innovations, industrial turntable bearings are not just components; they are key contributors to maximizing efficiency and reliability in heavy machinery applications.

Maintenance Best Practices for Maximizing Turntable Bearing Lifespan in Heavy Equipment

To maximize the lifespan of industrial turntable bearings in heavy machinery applications, implementing effective maintenance best practices is crucial. Regular inspections should be conducted to identify any signs of wear or damage. This includes checking for misalignment, abnormal noise, and vibration levels. Early detection of these issues can prevent more extensive damage and costly downtime.

Lubrication also plays a key role in bearing maintenance. Utilizing the correct type and amount of lubricant reduces friction and wear, enhancing overall performance. It's essential to maintain a consistent lubrication schedule and to ensure that the lubrication method matches the specific operational conditions of the machinery. Additionally, training operators on proper handling and usage can significantly impact the longevity of the bearings, as improper use often leads to premature failure. By adhering to these practices, operators can ensure that turntable bearings function efficiently and remain reliable in demanding environments.

Maximizing Efficiency with Industrial Turntable Bearings in Heavy Machinery Applications

| Maintenance Practice |

Frequency |

Tools Required |

Expected Lifespan Increase (%) |

Notes |

| Lubrication |

Monthly |

Grease gun, lubricant |

20% |

Ensure to use recommended lubricant type |

| Visual Inspection |

Weekly |

Inspection mirror, flashlight |

15% |

Check for signs of wear or damage |

| Sealing Examination |

Bi-Annually |

Seal puller, lubricant |

10% |

Replace seals if damaged or worn |

| Alignment Check |

Annually |

Laser alignment tool |

25% |

Proper alignment prevents uneven wear |

| Deep Cleaning |

Annual |

Cleaning solution, brushes |

30% |

Remove contaminants for better performance |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us