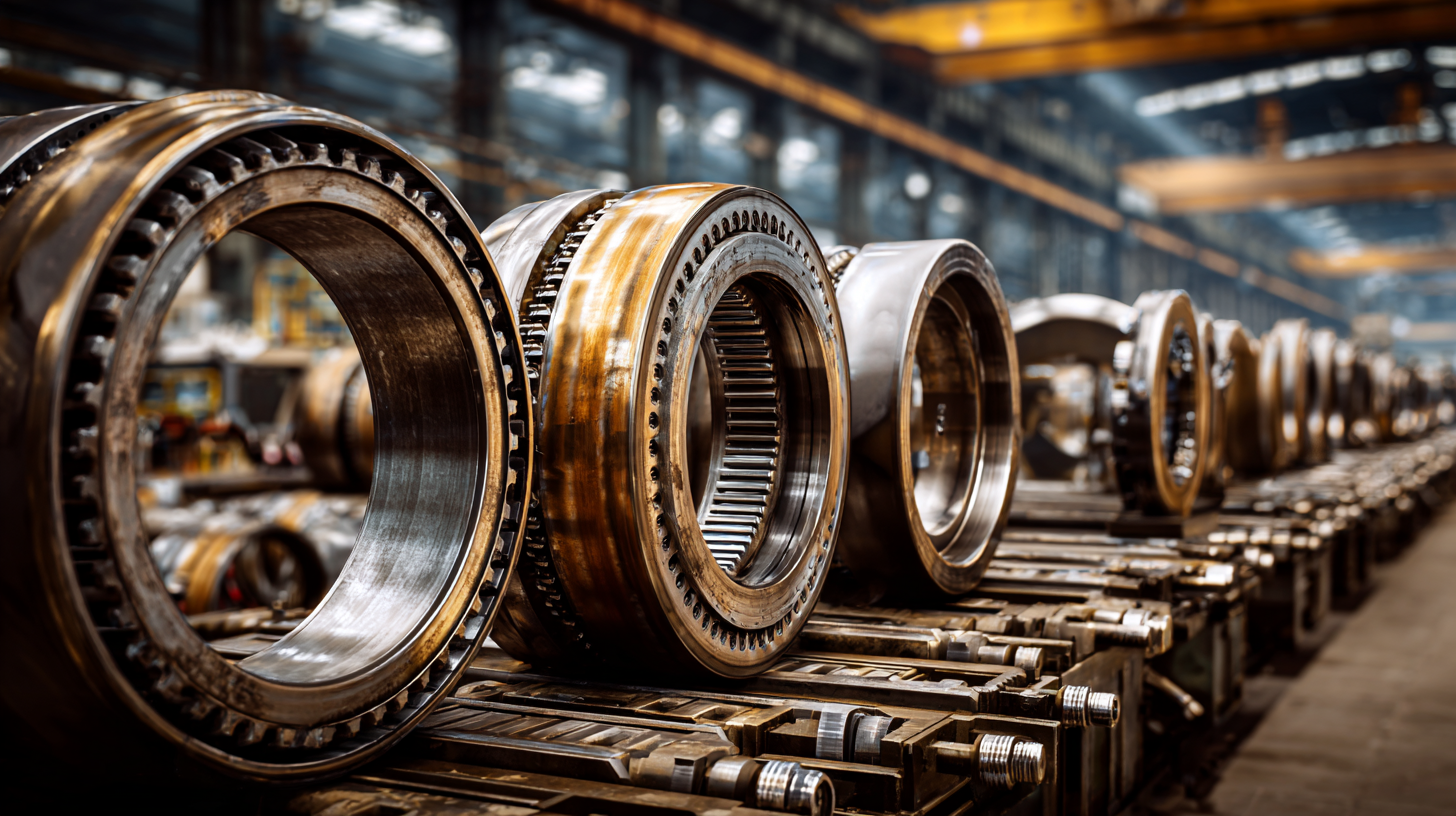

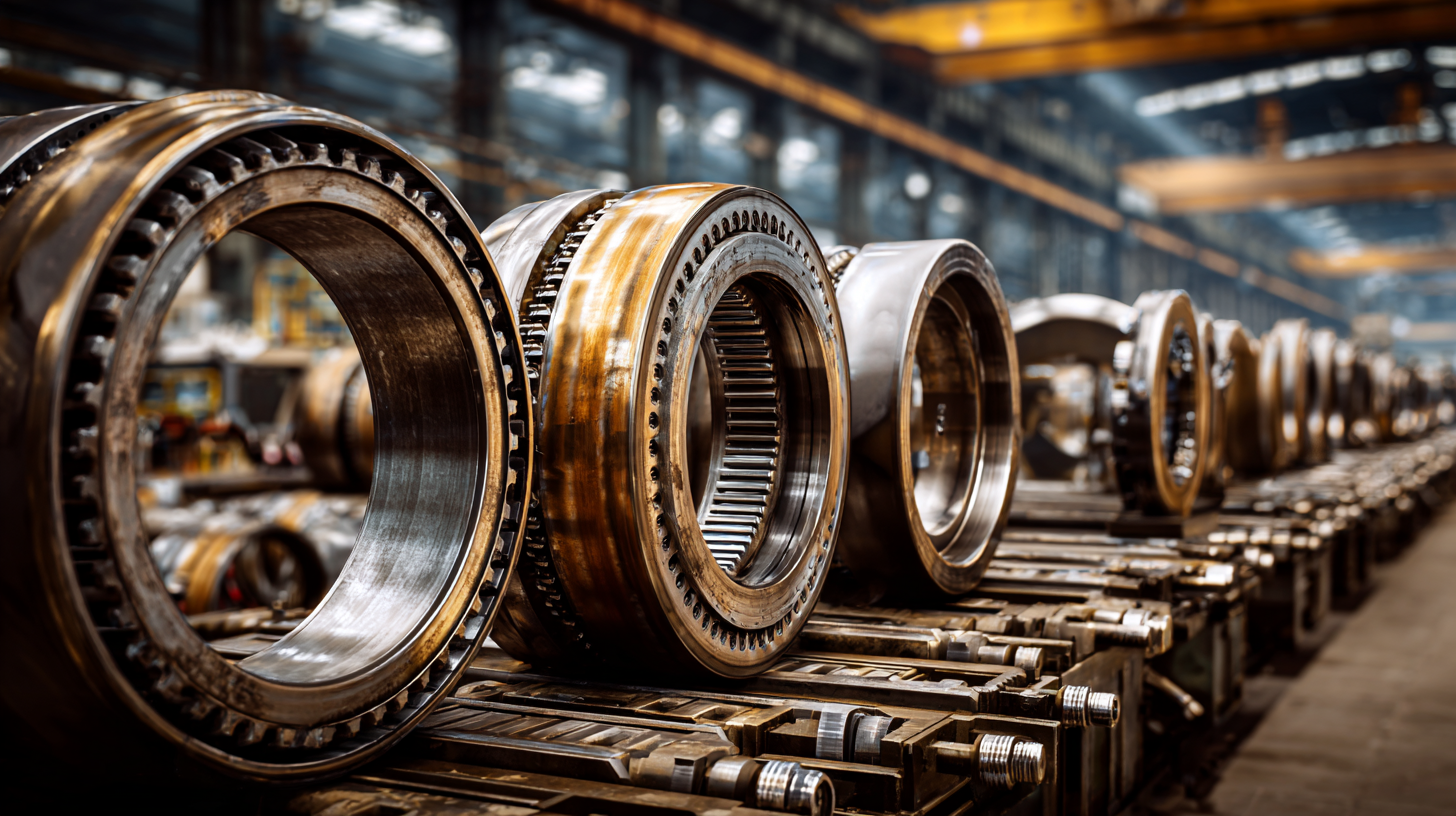

Unmatched Quality Steel Bearings Crafted in China for Global Excellence

As global manufacturing continues to evolve, the demand for high-quality components such as steel bearings is on the rise. According to a recent market research report, the global bearings market is expected to reach approximately $200 billion by 2025, driven in part by advancements in the automotive and aerospace industries. Steel bearings, known for their durability and performance, play a pivotal role in this growth. With China's expertise in metallurgy and engineering, the country stands out as a leading manufacturer, producing unmatched quality steel bearings that cater to diverse industrial applications. As we look ahead to 2025, the focus on innovation and quality control in the production of steel bearings will be crucial to sustaining global excellence and meeting the increasing demands of various sectors.

Applications of High-Quality Steel Bearings in Various Industries

High-quality steel bearings are essential components that drive a multitude of industries forward, showcasing unparalleled versatility and functionality. Made from advanced materials such as silicon, aluminum oxide, and zirconia, these bearings not only offer exceptional durability but also exhibit remarkable resistance to wear and corrosion. Their inert and active properties make them suitable for a variety of applications, including bearings for machinery, grinding equipment, and valve assemblies. The choice of material greatly impacts their performance, with silicon characterized by its high temperature resistance and aluminum oxide enhancing strength and stability.

As industries continue to evolve, the demand for efficient and reliable bearing solutions is on the rise. In sectors ranging from automotive to aerospace, the integration of advanced bearings can significantly improve productivity and reliability. For instance, in the automotive industry, high-quality steel bearings are pivotal in electric drive systems, where they must withstand extreme speeds and loads. Similarly, in aerospace applications, precision-engineered bearings contribute to the performance and safety of aircraft. This growing demand reflects a larger trend towards innovation and excellence in engineering, solidifying the role of high-quality steel bearings as critical players in global advancements.

Unmatched Quality Steel Bearings Crafted in China for Global Excellence - Applications of High-Quality Steel Bearings in Various Industries

| Application Area |

Bearing Type |

Material |

Load Capacity (kg) |

Speed Rating (rpm) |

| Automotive |

Deep Groove Ball Bearing |

Chrome Steel |

1000 |

12000 |

| Aerospace |

Angular Contact Bearing |

Ceramic |

750 |

18000 |

| Construction |

Spherical Plain Bearing |

Stainless Steel |

1500 |

8000 |

| Manufacturing |

Tapered Roller Bearing |

Alloy Steel |

1200 |

10000 |

| Electronics |

Sleeve Bearing |

Bronze |

300 |

5000 |

Innovative Techniques in Manufacturing Steel Bearings for Optimal Performance

The manufacturing of steel bearings in China has undergone a remarkable transformation, driven by innovative techniques that enhance their performance and sustainability. The latest advancements focus on optimizing production methods, introducing textured sliding bearings with unique patterns such as zigzag, herringbone, oval, and elliptical arrangements. These designs not only improve the friction characteristics but also contribute to the overall durability of the bearings, making them ideal for a variety of applications across different industries.

Moreover, the integration of new manufacturing technologies emphasizes cost-effectiveness while maintaining high-quality output. Techniques like advanced molding and precision machining are being employed to ensure that each bearing meets global standards of excellence. As industries demand higher efficiency and reliability, these innovations in steel bearing production are set to play a pivotal role in enhancing performance, thus positioning China as a leader in the global bearing market. This blend of innovation and quality is reshaping the future of mechanical components, ensuring that they meet the rigorous demands of contemporary engineering challenges.

Step-by-Step Guide to Selecting the Right Bearings for Your Project

When embarking on a project that requires steel bearings, selecting the right type can significantly impact the performance and longevity of your application. Start by understanding the load requirements of your project. Bearings are designed to handle different load types—radial, axial, or a combination. Evaluating the load capacity required can guide you in choosing a bearing that ensures optimal functionality.

Moreover, consider environmental factors that may affect bearing performance, such as temperature, humidity, and exposure to contaminants. For instance, if your application operates in a high-temperature environment, look for bearings with specialized materials or coatings to improve resistance.

**Tip:** Always consult the bearing manufacturer's specifications and recommendations concerning lubrication needs and maintenance schedules. Maintaining proper lubrication is crucial for prolonging the life of your bearings and ensuring smooth operation.

Lastly, don't overlook the importance of precision and quality. High-quality steel bearings, such as those crafted in China, offer unmatched durability and reliability, making them suitable for global applications. Be sure to verify certifications and quality standards to ensure you make the best selection for your project.

Quality Steel Bearings Production Overview

Maintenance Tips for Extending the Lifespan of Steel Bearings

When it comes to maintaining steel bearings, understanding the best practices can significantly extend their lifespan, ensuring optimal performance in various applications. Regular inspection is crucial, as it allows for the early detection of wear and tear. Dust, debris, and moisture can lead to rust and inefficiencies; therefore, keeping the bearings clean and dry is essential. Employing lubricants that are specially designed for steel bearings can also reduce friction and prevent overheating, which is critical in high-stress environments.

In infrastructure projects similar to the major maintenance currently underway on the M5 Oldbury viaduct, which was built in the 1970s, it's evident that proactive maintenance is vital. Just as the viaduct requires regular upkeep to endure the test of time, steel bearings in machinery and vehicles benefit from routine checks and replacements as needed. Innovations like hybrid bearings in electric vehicles further showcase the importance of advancements in bearing technology, as they help reduce energy losses, maximizing efficiency and performance. By applying these maintenance tips, users can ensure the longevity and reliability of steel bearings, whether in industrial applications or transportation systems.

Case Studies: Success Stories of Steel Bearings in Global Markets

The landscape of global manufacturing has seen a remarkable transformation, especially in the area of

steel bearings. Chinese manufacturers have not only embraced unmatched quality

but have also established successful partnerships with companies across various industries. One case study involves a German automotive company

that implemented Chinese steel bearings into their production line. The decision resulted in a

20% increase in operational efficiency, exemplifying how quality materials can directly enhance

performance and reliability.

When considering steel bearings for your project, it's vital to prioritize suppliers who adhere to

international quality standards. Evaluating certifications such as

ISO or ASTM can ensure that the bearings meet rigorous

safety and performance criteria. Moreover, engaging in dialogue with manufacturers about their production processes can provide insights into their

commitment to quality.

Another success story can be found in the renewable energy sector, where Chinese steel bearings are becoming increasingly popular for wind turbines.

By integrating these high-quality components, companies have reported reduced maintenance

costs and extended service life for their turbines, showcasing the long-term value that can be derived from investing in superior materials.

For businesses looking to optimize their supply chain, understanding the impact of material quality on overall productivity is crucial.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us