What is Steel Bearings? A Comprehensive Guide to Types and Applications

In the intricate world of machinery and engineering, steel bearings play an indispensable role in ensuring efficiency and durability. As an expert in the field, Dr. Emily Carter, a renowned mechanical engineer, once stated, "The reliability of steel bearings is crucial for the longevity and performance of modern machinery." This statement encapsulates the essence of steel bearings, highlighting their significance in various applications ranging from automotive components to aerospace technology.

Steel bearings are designed to endure heavy loads and reduce friction, making them a fundamental element in machinery. They come in various types, each tailored for specific applications, thereby impacting the performance and efficiency of equipment in multiple industries. As we delve into the comprehensive guide of steel bearings, we will explore the top five types that dominate the market in 2025, examining their unique properties, advantages, and varied applications. Understanding these essentials can guide manufacturers and engineers in making informed decisions that enhance operational performance and reliability through the proper use of steel bearings.

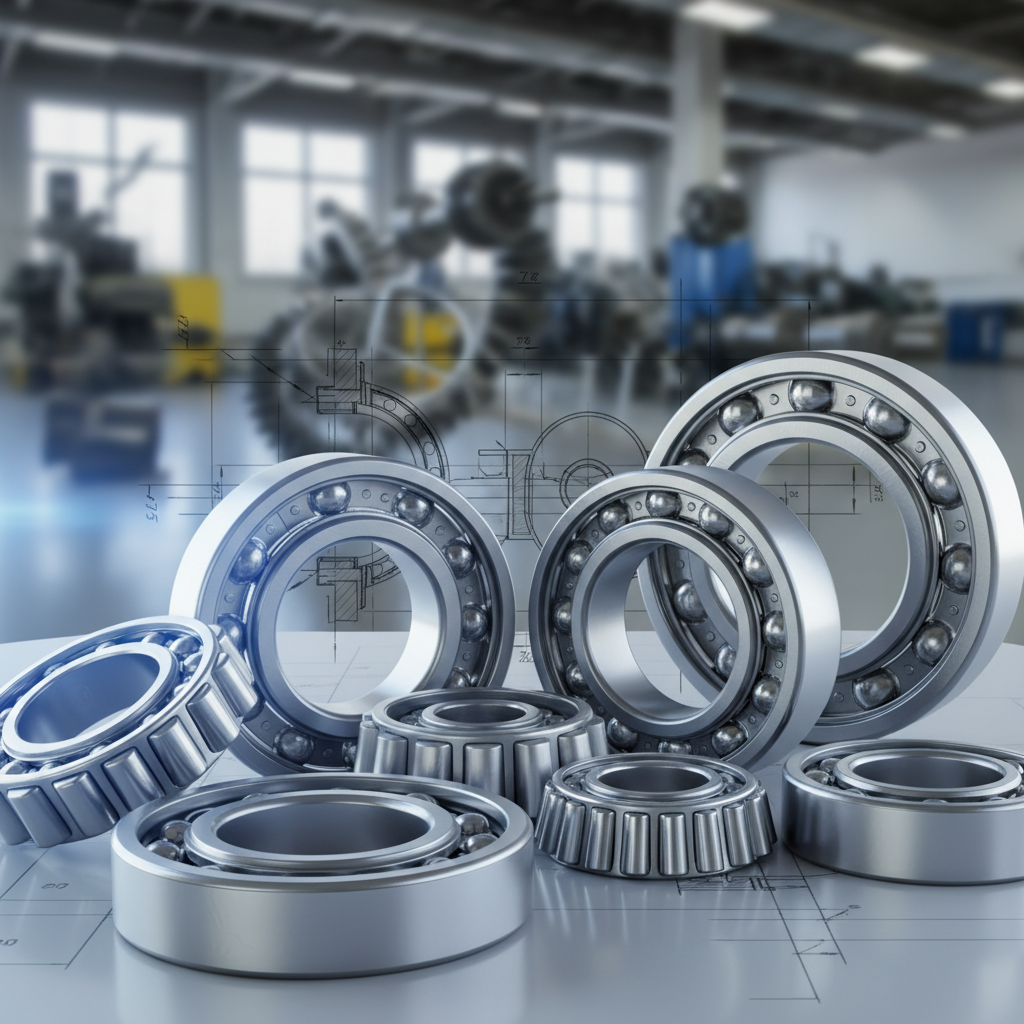

Overview of Steel Bearings: Definition and Key Characteristics

Steel bearings are crucial components in various mechanical systems, primarily designed to reduce friction between moving parts. Defined as cylindrical devices that support rotating shafts, they facilitate smooth motion in applications ranging from automotive to industrial machinery. Steel, known for its strength and durability, is the primary material used for these bearings, providing enhanced performance and a longer lifespan under demanding conditions.

Key characteristics of steel bearings include their load-bearing capacity, corrosion resistance, and ability to operate under a wide range of temperatures. These traits stem from the manufacturing process and the alloy compositions used in producing steel bearings.

Additionally, steel bearings can be categorized into various types, such as deep groove ball bearings, angular contact bearings, and roller bearings, each tailored for specific applications. This versatility makes them indispensable in numerous industries, where reliability and precision are paramount for optimal performance.

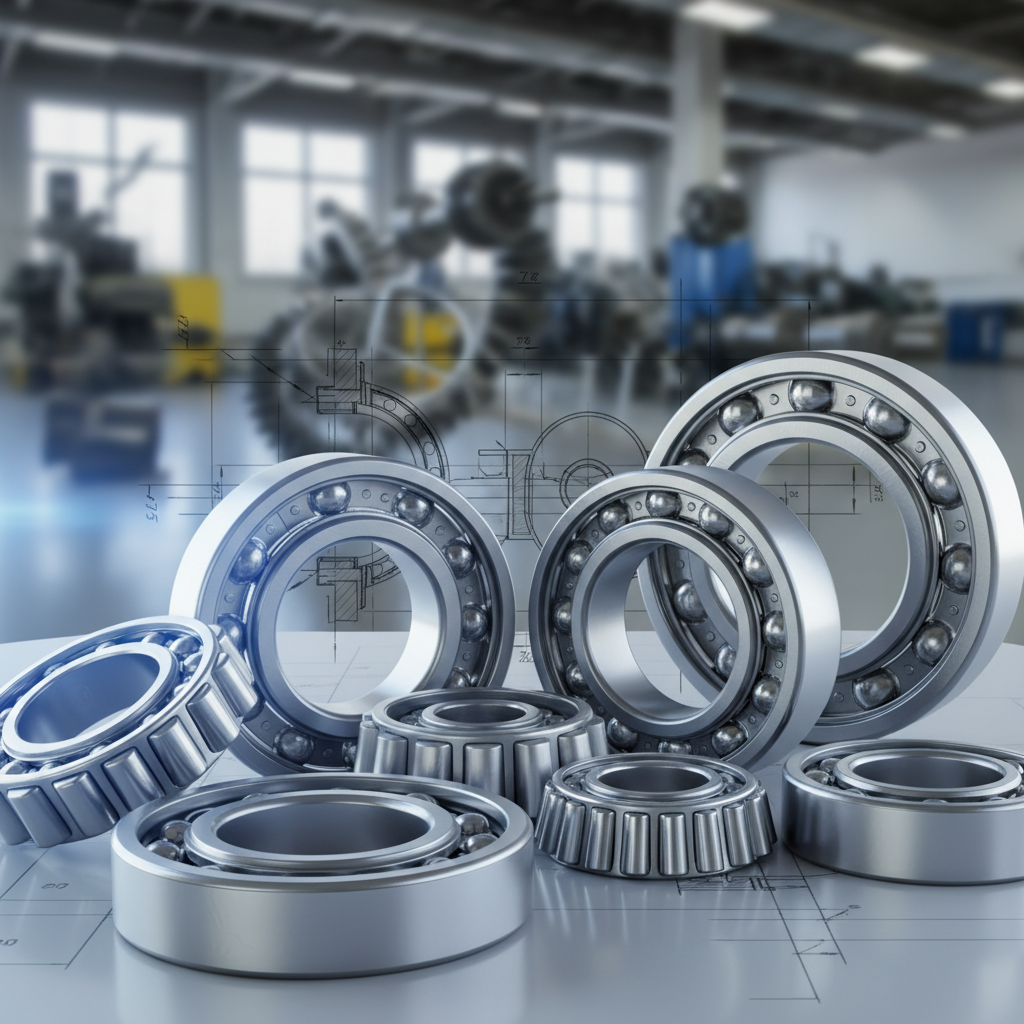

Types of Steel Bearings: A Detailed Comparison of Materials and Designs

Steel bearings are crucial components in various mechanical systems, allowing for smooth rotation and reducing friction between moving parts. There are several types of steel bearings, each designed for specific applications and environments. For instance, deep groove ball bearings are commonly used due to their versatility, handling both radial and axial loads efficiently. According to a recent market report by Grand View Research, the global ball bearing market size was valued at approximately $12.6 billion in 2022, and it is expected to expand at a CAGR of 7.0% from 2023 to 2030, underscoring the significance of these components in industrial applications.

When choosing the right type of steel bearing, consider the materials and designs involved. Stainless steel bearings are renowned for their corrosion resistance, making them suitable for high-humidity environments. In contrast, chrome steel bearings provide superior load capabilities and are widely used in automotive and aerospace sectors. According to a report by Markets and Markets, the demand for chrome steel bearings is projected to generate around $2.5 billion by 2025, driven by continuous innovations in manufacturing techniques and increasing consumption in high-performance applications.

Tips: When selecting steel bearings, always assess the working environment and load requirements. It's beneficial to consult with industry professionals to determine the best materials that can withstand specific stressors, ensuring longevity and reliability in your machinery. Additionally, regular maintenance and inspection can significantly enhance the lifespan of your bearings, leading to better overall performance.

Applications of Steel Bearings Across Various Industries: Insights and Trends

Steel bearings play a crucial role in a variety of industries due to their durability and high performance. Applications of steel bearings can be seen across sectors such as automotive, aerospace, manufacturing, and renewable energy, where reliable operation under extreme conditions is essential. In the automotive industry, steel bearings are integral to ensuring smooth and efficient movement in engines, wheels, and gears. Similarly, in aerospace, they contribute to the precise functioning of aircraft components, enhancing safety and performance.

The market trends indicate a growing demand for steel bearings, driven by advancements in technology and increased production in various sectors. As industries pivot towards more sustainable practices, the adoption of high-performance materials like steel bearings is on the rise. Projections suggest that the bearing steel market could expand to USD 8.9 billion by 2035, reflecting a steady growth rate. This trend not only underscores the importance of steel bearings in modern machinery but also highlights their adaptation to new challenges and technological innovations across diverse applications.

Performance Metrics: Understanding Load Capacity, Durability, and Efficiency

Steel bearings play a crucial role in various mechanical applications, with their performance metrics significantly impacting overall system efficiency. Load capacity is a primary consideration when selecting the appropriate bearing type. According to the American Society of Mechanical Engineers (ASME), the load-bearing capacity of steel bearings can vary widely, with standard radial ball bearings rated for loads ranging from 500 to over 10,000 pounds. Choosing the right bearing involves understanding how these load limits relate to the operational conditions, including the nature of the load (static or dynamic) and the expected service life.

Durability is another critical performance metric that defines how well steel bearings withstand wear over time. Industry reports indicate that well-lubricated steel bearings can operate effectively for several thousand hours under heavy load conditions. For example, a study by the National Institute of Standards and Technology (NIST) highlighted that high-quality steel bearings with proper maintenance can achieve a service life of 40% longer than standard counterparts. Furthermore, efficiency, characterized by minimized friction and heat generation, is essential for maximizing energy savings in industrial applications. Advanced materials and design innovations have led to bearings that reduce energy losses by as much as 20%, significantly improving the overall performance of machinery.

What is Steel Bearings? A Comprehensive Guide to Types and Applications

| Type of Steel Bearing |

Load Capacity (lbs) |

Durability Rating (Hours) |

Efficiency (%) |

Common Applications |

| Ball Bearings |

5,000 |

15,000 |

90 |

Motors, Fans, and Automobiles |

| Roller Bearings |

10,000 |

20,000 |

85 |

Conveyor Systems and Heavy Machinery |

| Thrust Bearings |

8,000 |

12,000 |

75 |

Generators and Pumps |

| Spherical Bearings |

6,000 |

18,000 |

80 |

Earthmoving Equipment and Agricultural Machines |

Future Trends in Steel Bearings: Innovations and Sustainability in Manufacturing

Steel bearings are vital components in various industries, especially in automotive applications, where the market is projected to grow significantly over the next decade. As sustainability becomes a key focus, innovations are driving the need for more efficient manufacturing processes. The global automotive bearing market was valued at

$14.76 billion in 2023 and is set to increase to $21.38 billion by 2032, reflecting a robust trend towards advanced materials and technologies in bearing production.

Tip: Companies looking to innovate in the steel bearing sector should invest in sustainable materials and processes. For instance, exploring the use of recycled steel in bearing manufacturing can not only reduce environmental impact but also lower costs over time.

Moreover, the carbon steel rebar market, which is essential for concrete applications, is also showing promising growth. The value of the carbon steel rebar market was $2.21 billion in 2022 and is anticipated to reach $3.05 billion by 2030, growing at a CAGR of 4.5% from 2024 to 2030. This growth mirrors similar trends in the bearing industry, indicating a broader movement towards sustainable practices across related sectors.

Tip: Businesses should consider collaborating with suppliers who prioritize sustainability to enhance their market position. Building partnerships with eco-conscious manufacturers can lead to innovations that benefit both the environment and profitability.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us