Essential Tips for Choosing the Right Automotive Bearings for Your Vehicle

In the dynamic world of automotive engineering, the selection of the right automotive bearings plays a crucial role in ensuring vehicle performance, safety, and longevity. According to a recent report by MarketsandMarkets, the global automotive bearings market is projected to reach approximately $29 billion by 2025, highlighting the increasing demand for quality components in vehicle manufacturing. This trend emphasizes the necessity for consumers and manufacturers alike to make informed decisions regarding the bearings that will ultimately sustain their vehicles’ performance.

Expert insights also underscore the significance of this topic. Dr. James Carter, a renowned specialist in automotive engineering, states, “The choice of automotive bearings can fundamentally affect not only the efficiency of vehicle operations but also the overall safety of the automaker's design.” His perspective illustrates the imperative for professionals and consumers to prioritize their selection process, evaluating factors such as load capacity, material composition, and application-specific requirements.

Choosing the right automotive bearings involves understanding the nuances of various types, characteristics, and their applications in different vehicle models. With the right knowledge and guidance, stakeholders can enhance vehicle performance, reduce maintenance costs, and ensure optimal operational efficiency in the competitive automotive landscape.

Understanding Different Types of Automotive Bearings Available

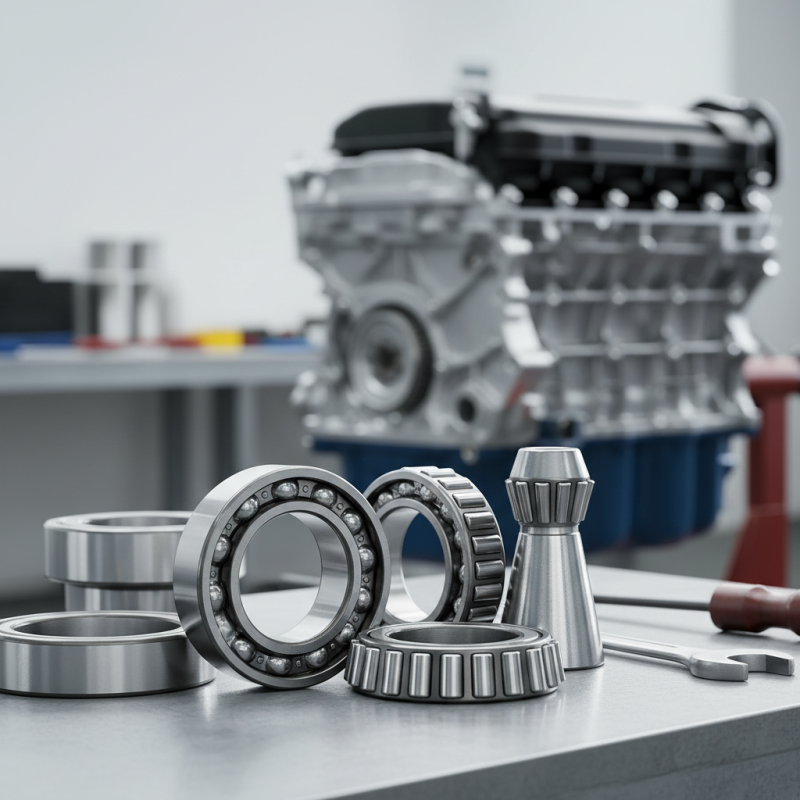

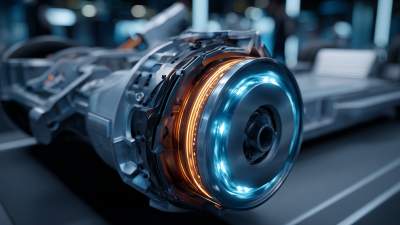

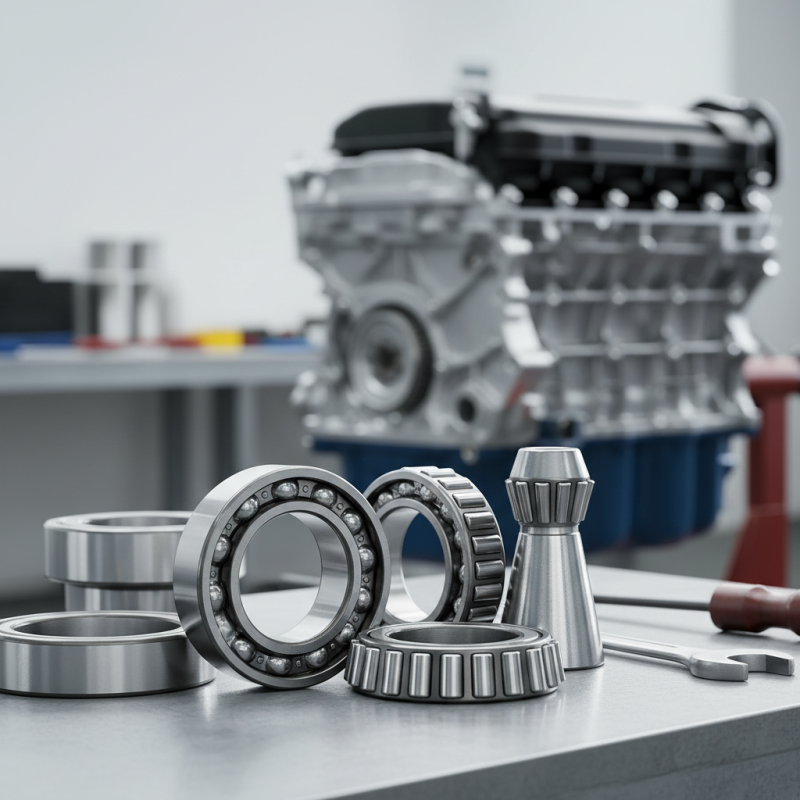

When selecting automotive bearings for your vehicle, it's crucial to understand the various types available, as they serve different functions and performance requirements. The most commonly used bearings in automotive applications include ball bearings, roller bearings, and tapered roller bearings. Ball bearings are characterized by their ability to support both radial and axial loads, making them ideal for components such as wheel hubs and electric motors. Their design offers low friction and high-speed capabilities, which are essential for smooth vehicle operation.

Roller bearings, on the other hand, are designed to accommodate heavier loads due to their larger contact area with the raceway. They are often utilized in applications requiring durability and strength, such as in drivetrain components and suspension systems. Tapered roller bearings combine features of both ball and roller bearings; they can handle significant radial and axial loads and are commonly found in wheel bearings and differential assemblies. Understanding these types allows vehicle owners to make informed decisions that enhance performance and reliability.

Key Factors to Consider When Selecting Automotive Bearings

When selecting automotive bearings, there are several key factors to consider to ensure optimal performance and longevity for your vehicle. One of the primary aspects is the bearing type; it’s crucial to understand whether you need ball bearings, roller bearings, or tapered roller bearings, each serving different purposes and loads. A 2022 industry report indicated that proper bearing selection can enhance the lifespan of critical automotive systems by up to 30%.

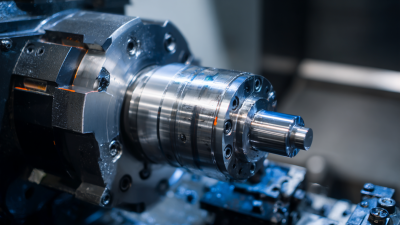

Another important consideration is the bearing material. Bearings constructed from high-carbon chrome steel often provide superior durability and resistance to wear, which is vital for vehicles that experience high levels of stress and heat. Data from a recent automotive engineering survey highlighted that improper material selection can lead to premature bearing failure, which in turn affects vehicle safety and performance.

Tips: Always ensure that the bearings meet the necessary specifications for your vehicle model and driving style. It’s also beneficial to consult with industry professionals or reference comprehensive performance data to delve into the material science behind different bearing options. Lastly, keep an eye on the lubrication type and maintenance recommendations, as these factors significantly impact the overall effectiveness and reliability of the bearings over time.

Assessing Bearing Quality and Manufacturer Reputation

When selecting automotive bearings, assessing the quality of the bearings and the reputation of the manufacturer is crucial for ensuring longevity and performance. High-quality bearings are designed to withstand the demands of vehicle operation, minimizing wear and tear over time. Look for materials and manufacturing processes that meet or exceed industry standards. This includes checking for features such as precision engineering, appropriate load ratings, and resistance to environmental factors like moisture and dust. Understanding these attributes helps in making an informed decision that aligns with your vehicle's specific needs.

In addition to bearing quality, the reputation of the manufacturer plays a significant role in your selection process. A manufacturer known for reliability and innovation not only provides insights into their production methods but also offers warranties and customer support that can be invaluable in the long run. Research customer reviews and ratings to gauge how previous users have experienced the bearings. Reliable manufacturers often invest in research and development, indicating a commitment to quality and advancement, which can lead to performance enhancements. By prioritizing quality and reputable sources, you can ensure that the bearings you choose will provide optimal functionality and durability for your vehicle.

The Importance of Proper Sizing in Automotive Bearings

When it comes to automotive bearings, proper sizing is crucial for ensuring optimal vehicle performance and longevity. Bearings are designed to support the loads and facilitate the rotation of components like wheels and axles. According to the National Lubricating Grease Institute (NLGI), improper bearing sizing can lead to increased friction, higher operating temperatures, and ultimately, premature failure of the bearings. The correct bearing size ensures that load distribution is balanced, decreasing wear and tear and maintaining effective lubrication, which is essential for the smooth operation of any vehicle.

Furthermore, the International Organization for Standardization (ISO) reports that an estimated 70% of bearing failures in the automotive industry are attributed to incorrect sizing and installation. When selecting bearings, it's vital to consider not just the dimensions but also the load specifications of your vehicle. Using a bearing that is either too large or too small can create alignment issues that further lead to complications such as misalignment, vibration, and even damage to other parts of the vehicle. To avoid these issues, always refer to manufacturer specifications and consult with professionals if you're uncertain about the requirements. Proper sizing is not just a matter of fitting; it plays a significant role in the overall reliability and efficiency of your vehicle’s performance.

Essential Tips for Choosing the Right Automotive Bearings for Your Vehicle

This chart represents the importance of proper sizing in automotive bearings based on various factors including load capacity, speed capability, and cost. Properly sized bearings can significantly affect vehicle performance and longevity.

Maintenance Tips for Maximizing Bearing Lifespan in Vehicles

Maintaining automotive bearings is crucial for ensuring optimal vehicle performance and longevity. One of the most effective ways to maximize the lifespan of bearings is through regular inspection and lubrication. Checking for any signs of wear or damage, such as cracks or excessive play, can help identify issues before they escalate. Additionally, utilizing the appropriate lubricant according to the manufacturer's specifications is essential. Proper lubrication reduces friction, minimizes heat buildup, and helps keep contaminants at bay, which in turn enhances the bearing's efficiency and durability.

Heat management also plays a vital role in the longevity of automotive bearings. Bearings operating under high temperatures may suffer from accelerated wear and reduced performance. To combat this, ensure that your vehicle's cooling system is functioning correctly and that airflow to critical components is unobstructed. Furthermore, avoiding overloading your vehicle can significantly reduce stress on the bearings, allowing them to perform optimally for longer periods. Adopting these maintenance practices will not only extend the life of your bearings but will also contribute to the overall reliability of your vehicle.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us