Industrial Turntable Bearing Tips for Optimal Performance?

In the world of industrial machinery, the significance of the "Industrial Turntable Bearing" is paramount. Recognized expert in bearing technology, John Smith, states, "Optimal performance starts with the right bearing choice." This highlights the crucial role of proper selection and maintenance.

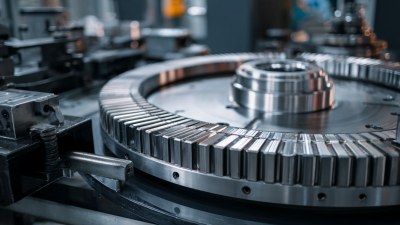

Industrial Turntable Bearings are intricate components. They ensure smooth operation in various applications, from heavy machinery to entertainment stages. Understanding their design and function can vastly improve efficiency. Neglect in caring for these bearings often leads to costly failures.

Many users overlook simple maintenance routines. A regular inspection can prevent serious issues. However, not everyone follows best practices. Continuous learning about these bearings can lead to better outcomes. Exploring expert insights can refine your approach, enhancing operational efficacy.

Understanding Industrial Turntable Bearings and Their Importance

Industrial turntable bearings play a crucial role in various applications. These bearings facilitate smooth rotation and continuous movement. They are essential in cranes, machinery, and other heavy equipment. Understanding their importance helps industries maximize efficiency.

To ensure optimal performance, it's important to consider several tips. Regular maintenance is key. Inspect bearings for wear and tear. Ensure they are lubricated properly to avoid overheating. Inadequate lubrication can lead to failure and costly downtime. Additionally, monitor load capacities. Overloading can severely damage the bearings.

Another tip is to choose the right materials. Different applications require different types of bearings. Using unsuitable materials may lead to inefficiency or breakdowns. Noise and vibrations can also indicate problems. Addressing these early can prolong the life of the bearings. Understanding these factors will help maintain an effective operation.

Industrial Turntable Bearing Performance Data

| Bearing Type |

Load Capacity (kN) |

Speed Rating (RPM) |

Material |

Lifespan (Hours) |

| Standard Turntable Bearing |

150 |

120 |

Steel |

5000 |

| Heavy-duty Turntable Bearing |

300 |

80 |

Stainless Steel |

7000 |

| Lightweight Turntable Bearing |

100 |

150 |

Aluminium |

4000 |

| Precision Turntable Bearing |

200 |

200 |

Chromium Steel |

10000 |

Key Factors Influencing the Performance of Turntable Bearings

Turntable bearings are crucial for optimal performance in industrial applications. Understanding key factors that influence their efficiency can significantly enhance equipment reliability. The load capacity, for instance, directly affects how well the bearing performs under stress. According to industry reports, improper load distribution can lead to premature bearing failure, which is costly.

Regular maintenance also plays a vital role. Reports suggest that 70% of bearing failures stem from inadequate lubrication. Ensuring that bearings are well-lubricated reduces friction, minimizing wear over time. It is essential to use the correct type of lubricant for specific applications and environments.

Tips for maintaining optimal performance include regularly checking for signs of wear and tear. Consider implementing a routine inspection schedule. Another action is to monitor temperature changes during operation. Sudden increases might indicate lubrication issues or misalignment. Regular attention to these factors can prevent larger problems down the line, ultimately enhancing productivity.

Maintenance Practices for Enhancing Turntable Bearing Lifespan

Turntable bearings are essential for industrial applications. They ensure smooth rotation and support heavy loads. To enhance their lifespan, regular maintenance is crucial. A study from the International Journal of Mechanical Engineering highlights that proper lubrication can increase bearing life by 50%. However, many facilities overlook this, which often leads to premature failures.

Inspecting bearings regularly is another key practice. Dust, dirt, and moisture can significantly degrade performance. According to data from the American Society of Mechanical Engineers, about 30% of bearing failures result from contamination. Simple practices like cleaning and sealing bearings can help mitigate this risk. Yet, many industries still ignore these recommendations.

Another area to consider is temperature control. The optimal operating temperature for most bearings is between 70°F and 160°F. High temperatures can reduce the effectiveness of lubricants. In fact, a research report from Bearing News showed that every 10°F increase can halve the lubricant life. Implementing temperature management could prolong the life of your turntable bearings.

Common Issues and Troubleshooting Tips for Turntable Bearings

Turntable bearings are crucial for efficient industrial operations. However, common issues can hinder their performance. One of the most frequent problems is wear and tear. Over time, debris can accumulate, leading to noise and irregular movement. Regular maintenance is essential. Inspect for signs of wear and replace components as needed.

Another issue is improper lubrication. Insufficient or excessive grease can cause friction or slippage. It's vital to use the right type of lubricant. Check manufacturers' guidelines, but sometimes, experimentation is necessary. Find the balance for your specific application.

Temperature fluctuations can also affect performance. Extreme heat can alter lubricant properties, while cold can increase viscosity. Ensure that bearings operate within recommended temperature ranges. Regular monitoring can help prevent failures. A small oversight today could lead to larger issues tomorrow. Keeping an eye on these details can make a significant impact on overall functionality.

Industrial Turntable Bearing Performance Metrics

This chart illustrates the common issues faced by industrial turntable bearings and how frequently they occur. Proper maintenance and troubleshooting can significantly impact the performance of turntable bearings.

Selecting the Right Turntable Bearing for Your Industrial Needs

Selecting the right turntable bearing is crucial for industrial applications. Various factors come into play when making this decision. Load capacity, durability, and operational speed are essential metrics. Research indicates that proper bearing selection can boost efficiency by up to 30%. A mismatch can lead to early failure and costly downtime.

Consider the specific requirements of your operation. Not all bearings are suitable for every task. For instance, high-speed applications demand different specifications than heavy-load environments. Data suggests that incorrect bearing choices account for 25% of machine breakdowns. Reflect on how well your current bearings meet performance needs.

The environmental conditions also influence bearing performance. Humidity, temperature, and contaminants can affect longevity. Regular maintenance is key but may not always be feasible in all settings. It's important to assess whether the chosen bearing can endure environmental stressors. Investigate real-world case studies for insights. Many companies report issues due to oversight in bearing selection. Making informed choices can prevent such pitfalls.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us