Top 10 Angular Bearings: Key Specifications, Benefits, and Industry Insights

In the world of machinery and equipment, Angular Bearings play a crucial role in enhancing performance and operational efficiency. These specialized bearings are designed to accommodate both radial and axial loads, making them essential for a wide range of industrial applications, from automotive to aerospace. According to a recent industry report from Market Research Future, the global bearing market is projected to reach USD 80 billion by 2025, with Angular Bearings expected to significantly contribute to this growth due to their reliability and versatility.

The increasing demand for high-performance machinery has further propelled the adoption of Angular Bearings across various sectors. As manufacturers strive for precision engineering and improved performance metrics, the unique characteristics of Angular Bearings—such as their ability to bear heat and handle heavy loads—become paramount. In fact, a study by the International Journal of Engineering & Technology highlighted that implementing advanced bearing solutions can lead to a 40% increase in operational efficiency for heavy machinery.

In this article, we present the top 10 Angular Bearings available in the market today, detailing their key specifications, benefits, and industry insights. By understanding the intricacies of these critical components, businesses can make informed decisions that not only enhance machinery performance but also reduce maintenance costs and downtime.

Top Angular Bearings: An Overview of Types and Functions

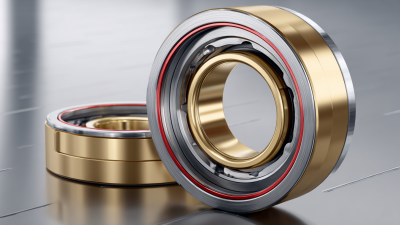

Angular bearings play a crucial role in various mechanical applications, particularly where load direction and rotational speed require reliable performance. These bearings are designed to accommodate both axial and radial loads, making them ideal for machinery such as electric motors, automotive systems, and industrial machines. Typically, angular contact bearings come in different configurations, including single-row and double-row designs, allowing for tailored solutions depending on specific operational needs.

Recent industry insights reveal that the sliding bearing market is projected to reach $1.9 billion by 2030, underscoring the growing demand for advanced bearing solutions across multiple sectors. Notably, the automotive industry relies heavily on angular bearings for their ability to handle the complex loading conditions in vehicles. For instance, front-wheel angular contact ball bearings are engineered to manage increased loads while maintaining lower friction and enhanced durability, which addresses the common challenges of seal drag in external-type designs. Understanding these specifications is essential for engineers and manufacturers looking to enhance performance and extend the lifespan of critical components in their systems.

Key Specifications to Consider When Choosing Angular Bearings

When selecting angular bearings, several key specifications should be prioritized to ensure optimal performance and longevity. First and foremost, the load rating is critical; it indicates the maximum weight the bearing can support without risk of failure. Understanding both the dynamically and static load ratings will allow engineers to gauge the bearing's capabilities under actual working conditions. Additionally, the bore size—the diameter of the bearing’s inner ring—must match the shaft size precisely; an incorrect fit can lead to premature wear or damage.

Another essential specification is the lubrication type, which plays a significant role in reducing friction and heat generation. Bearings can be pre-lubricated or require periodic maintenance, and the choice of lubricant—such as grease or oil—can influence operational efficiency and lifespan. Lastly, operating temperature range should not be overlooked; angular bearings need to perform under varying thermal conditions, which can affect material properties and overall functionality. By considering these specifications, one can ensure that the chosen angular bearing meets the demands of its intended application.

Benefits of Using Angular Bearings in Various Industries

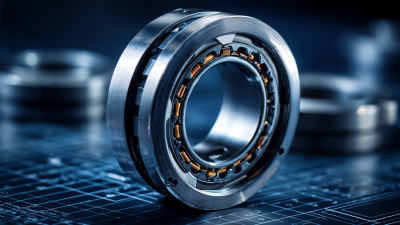

Angular bearings play a crucial role in a variety of industries due to their unique design and capabilities. These bearings are engineered to handle both radial and axial loads simultaneously, making them ideal for applications where space is constrained, and load direction is variable. Industries such as automotive, aerospace, and manufacturing benefit significantly from their ability to maintain high precision and stability under dynamic conditions. This versatility enables smoother operation of machinery, ultimately leading to enhanced productivity and reduced maintenance costs.

In addition, angular bearings are renowned for their durability and longevity, which are critical factors in industrial settings. Their ability to operate efficiently under high speeds and extreme conditions allows for extended service life and minimized downtime. For example, in the aerospace industry, these bearings ensure reliable performance in aircraft systems, where even minor failures can lead to significant safety concerns. Moreover, the use of angular bearings contributes to energy efficiency, which is increasingly important in today's eco-conscious markets, further emphasizing their value across various sectors.

Insights into the Manufacturing Process of Angular Bearings

The manufacturing process of angular bearings involves several intricate steps that ensure precision and performance in various applications. Initially, high-quality materials, such as steel or ceramic, are selected for their strength and durability. These materials undergo thermal treatment processes to enhance their mechanical properties, which is crucial for the bearings' resistance to wear and fatigue. Afterward, the components are precisely machined to achieve the necessary tolerances, followed by surface finishing techniques, such as grinding or honing, to provide a smooth surface that reduces friction during operation.

Quality control plays a vital role throughout the manufacturing process of angular bearings. Each batch is subjected to rigorous testing to measure parameters such as dimensional accuracy, hardness, and noise levels. This ensures that only the best products reach the market, maintaining high standards of reliability and performance. With the bearings market projected to grow significantly, innovations in manufacturing techniques, including automation and additive manufacturing, are evolving, driving efficiency and paving the way for the development of more advanced bearing solutions responsive to industry needs.

Common Applications and Use Cases for Angular Bearings

Angular bearings are widely utilized in various industries due to their unique ability to handle both radial and axial loads. Common applications include automotive, aerospace, and machinery manufacturing, where they enhance performance and longevity. In the automotive sector, angular bearings are crucial for steering systems and wheel assemblies, providing precision and stability. The aerospace industry also employs these bearings in engine components and landing gear systems, owing to their reliability under challenging conditions.

Tips: When selecting angular bearings for specific applications, consider factors such as load capacity, speed ratings, and environmental conditions. Additionally, regular maintenance can significantly extend the life of these bearings, ensuring optimal performance and reducing downtime.

The growing global bearing market, expected to reach $468.2 billion in 2024, is a testament to the increasing reliance on these components across sectors. The hybrid ceramic bearing market is also on an upward trajectory, projected to rise from $36 million in 2025 to $551 million by 2034. This growth reflects the ongoing demand for advanced materials and designs that enhance efficiency and reduce friction in critical applications.

Top 10 Angular Bearings: Key Specifications and Benefits

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us