2025 Top 5 Radial Ball Bearings for Enhanced Performance in Industrial Applications

In the world of industrial applications, the importance of selecting the right components cannot be overstated. Among these critical components, Radial Ball Bearings play a vital role in ensuring the smooth operation and efficiency of machinery. As we look towards the future, specifically in 2025, the need for enhanced performance in manufacturing processes drives the demand for advanced bearing technologies. Renowned expert in the field, Dr. Emily Carter, emphasizes this trend by stating, "The evolution of Radial Ball Bearings is crucial for industries aiming to improve their operational efficiency and reliability."

As industries seek to optimize their machinery and reduce downtime, understanding the features and benefits of Radial Ball Bearings becomes essential. The top choices available in the market can significantly impact performance, longevity, and maintenance costs. This exploration of the best radial ball bearings for 2025 aims to guide engineers and decision-makers in selecting products that align with their performance goals and operational demands. The future of industrial applications hinges on the capabilities of these pivotal components, making it imperative to stay informed about the latest advancements in Radial Ball Bearings.

Key Features of Radial Ball Bearings for Industrial Efficiency

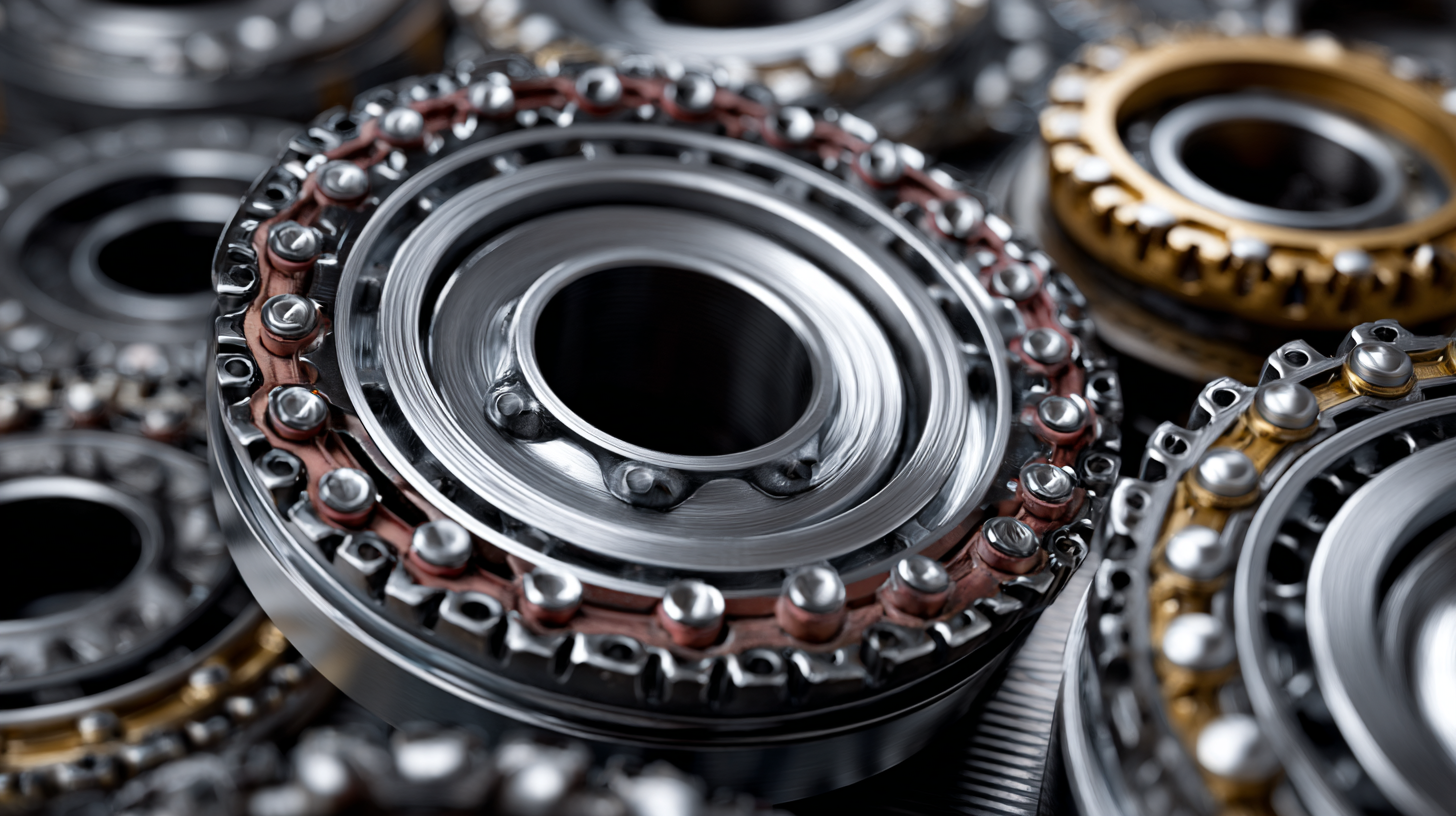

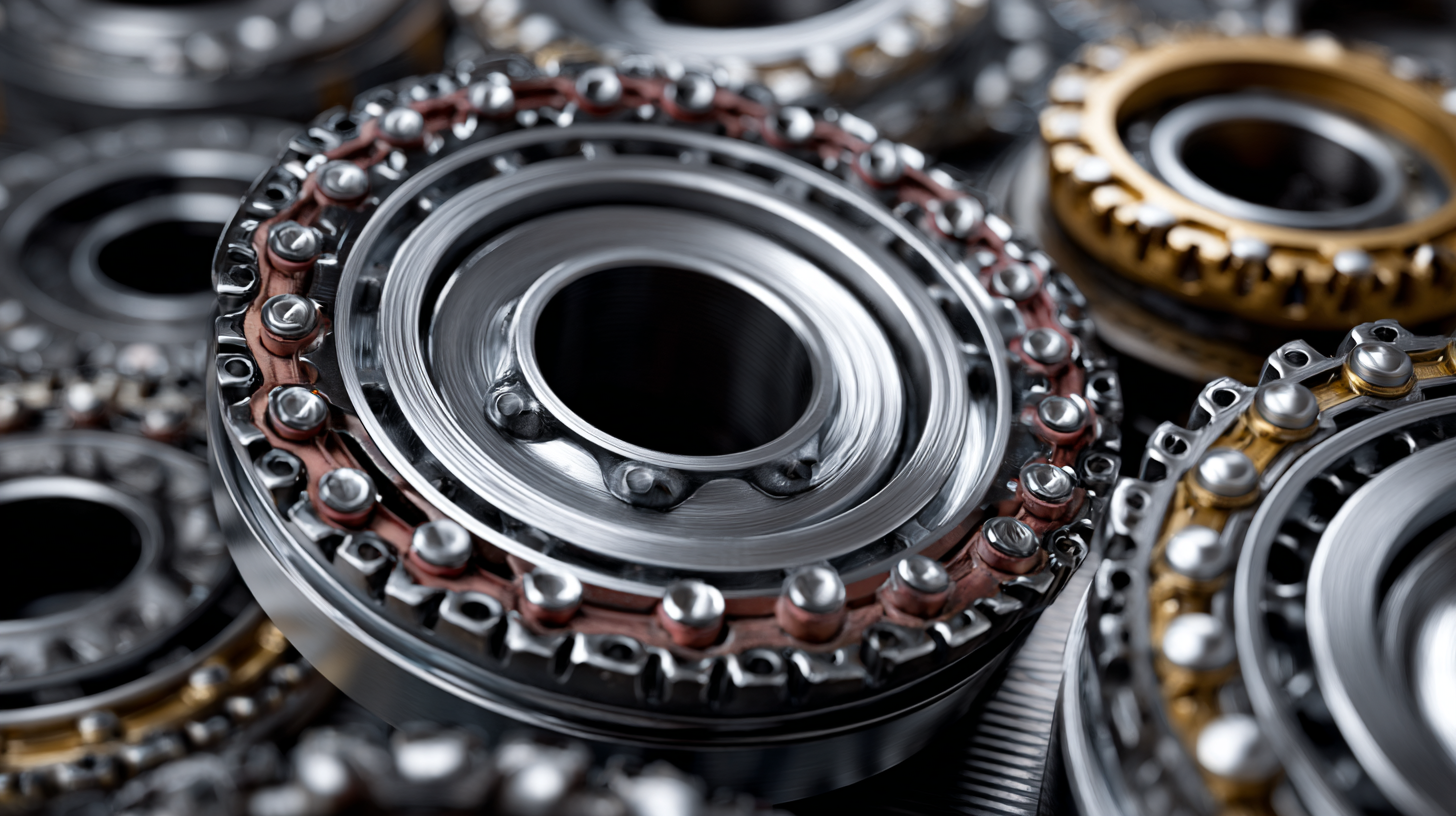

Radial ball bearings play a crucial role in enhancing industrial performance by providing reliable solutions for rotating machinery. Their design comprises rolling elements positioned between inner and outer rings, which significantly reduces friction and supports efficient operation. Key features contributing to their industrial efficiency include high load-carrying capacity, low frictional resistance, and durability under various operating conditions. These attributes make them suitable for a wide range of applications, from automotive to heavy machinery.

Radial ball bearings play a crucial role in enhancing industrial performance by providing reliable solutions for rotating machinery. Their design comprises rolling elements positioned between inner and outer rings, which significantly reduces friction and supports efficient operation. Key features contributing to their industrial efficiency include high load-carrying capacity, low frictional resistance, and durability under various operating conditions. These attributes make them suitable for a wide range of applications, from automotive to heavy machinery.

In recent years, there has been a marked increase in the demand for advanced diagnosis techniques aimed at monitoring bearing health. Incorporating modern technologies, such as adaptive frequency enhanced attention and deep learning algorithms, has improved fault detection capabilities. Techniques involving deep groove ball bearings (DGBBs) not only streamline operations but also ensure optimal performance longevity. As the market for radial ball bearings continues to expand, understanding these key features will be essential for industries seeking to improve their operational efficiency and product reliability.

Comparative Analysis of Top Radial Ball Bearings: Performance Metrics

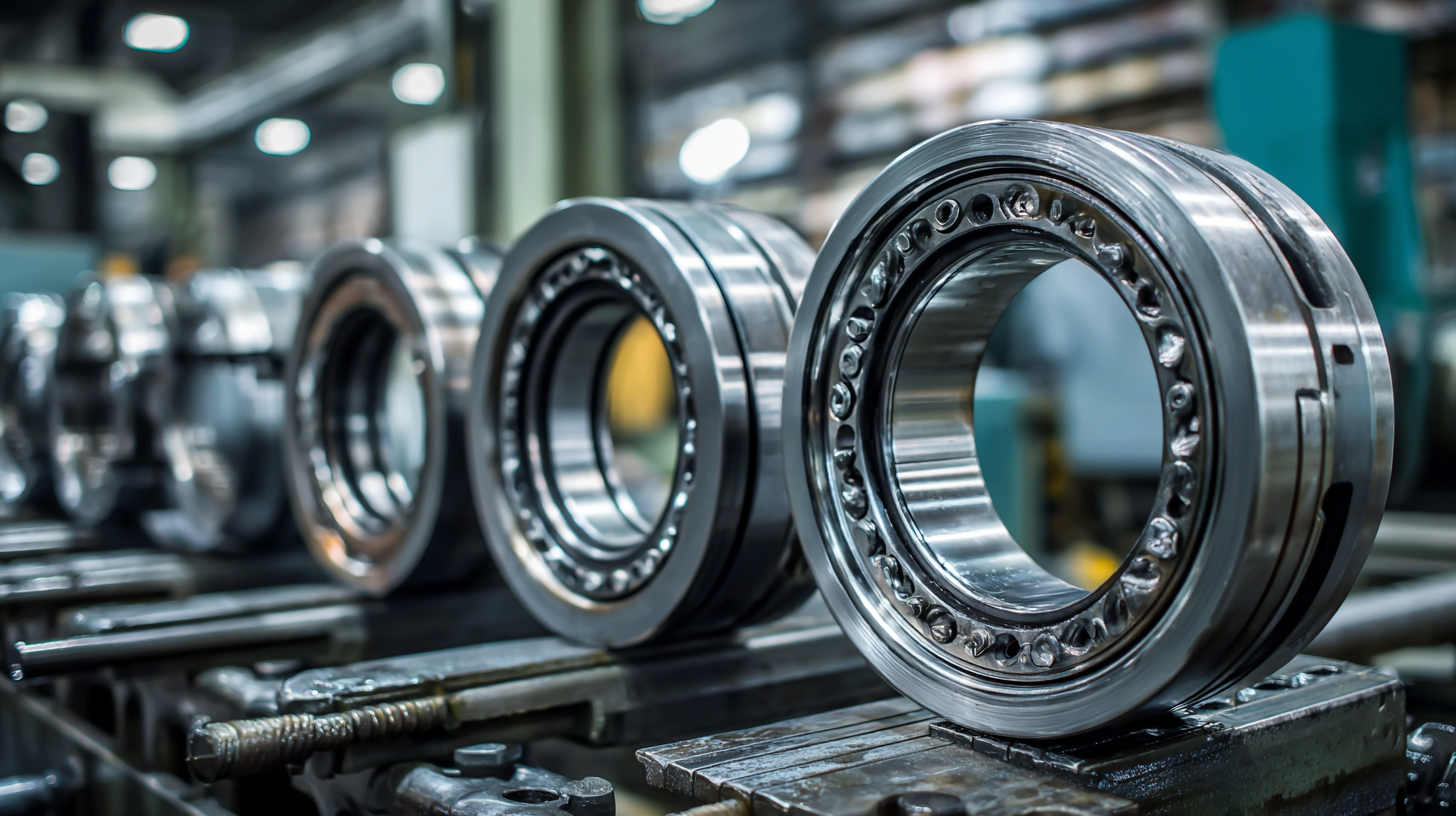

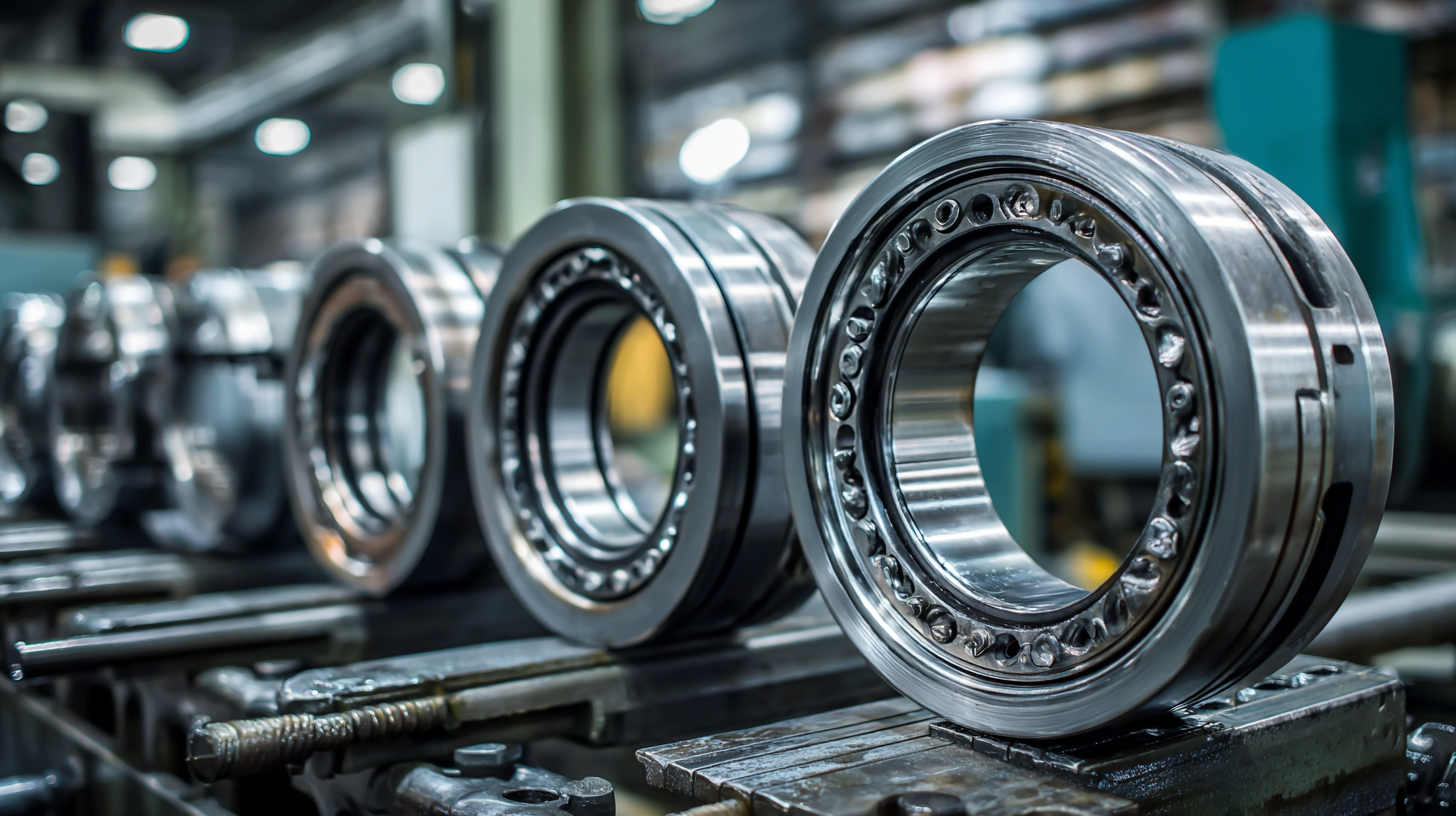

When selecting radial ball bearings for industrial applications, performance metrics play a crucial role in ensuring optimal functionality and longevity. Top contenders in the market demonstrate exceptional load capacity, reduced friction, and enhanced rotational speed characteristics. For instance, bearings constructed from high-quality materials, like stainless steel or ceramic, offer not only durability but also improved resistance to environmental factors such as moisture and temperature variations.

**Tips:** When assessing bearings, always consider the application requirements. Take into account the maximum load the bearing will bear and the speed at which it will operate. Additionally, check for lubrication types that can affect performance; using the right lubricant can drastically reduce wear and noise, ensuring smoother operation.

Another critical metric to analyze is the bearing's internal clearance and seal quality. These features can significantly impact performance and lifespan. A well-designed seal can prevent contamination, while appropriate clearance allows for thermal expansion, keeping the bearing in optimal conditions. This comparative analysis of specifications will guide users in selecting the best radial ball bearings tailored to their specific industrial needs.

**Tips:** Don't overlook maintenance schedules. Regular inspections and timely lubricant replacements can enhance the performance and extend the service life of bearings considerably.

2025 Top 5 Radial Ball Bearings for Enhanced Performance in Industrial Applications - Comparative Analysis of Top Radial Ball Bearings: Performance Metrics

| Bearing Model |

Load Capacity (N) |

Speed Rating (RPM) |

Temperature Range (°C) |

Service Life (Hours) |

| Model A |

5000 |

2000 |

-20 to 120 |

15000 |

| Model B |

6000 |

2500 |

-30 to 130 |

18000 |

| Model C |

5500 |

2300 |

-20 to 110 |

16000 |

| Model D |

7000 |

2700 |

-40 to 140 |

20000 |

| Model E |

6500 |

2400 |

-25 to 125 |

17000 |

Innovative Materials and Technologies in 2025 Radial Ball Bearings

The evolution of radial ball bearings in 2025 is marked by the incorporation of innovative materials and advanced technologies that significantly enhance their performance in industrial applications. One of the most notable advancements is the use of ceramic materials, which not only provide superior wear resistance but also minimize friction, leading to increased efficiency and lifespan. These ceramic bearings can withstand higher temperatures and aggressive environments, making them ideal for high-speed machinery and demanding applications.

In addition to materials, the integration of smart technologies into radial ball bearings is revolutionizing their functionality. Sensors embedded within the bearings allow for real-time monitoring of temperature, load, and vibration, enabling predictive maintenance and reducing the risk of unexpected failures. This smart capability enhances operational efficiency and reliability, giving manufacturers a competitive edge. As industries strive for improved performance and sustainability, the development of these advanced radial ball bearings represents a significant leap forward in engineering and technology.

2025 Top 5 Radial Ball Bearings Performance Overview

Applications and Industry Sectors Benefiting from Enhanced Bearings

In the industrial landscape, radial ball bearings have become instrumental in optimizing equipment performance across various sectors. Industries such as manufacturing, automotive, and aerospace rely heavily on these enhanced bearings to reduce friction, improve efficiency, and extend the lifespan of machinery. By integrating advanced materials and designs, these bearings facilitate smoother operations, allowing industries to meet increasing production demands while minimizing downtime.

Tip: Always assess the specific load requirements and environmental conditions of your application when selecting radial ball bearings. This ensures optimal performance and longevity.

Moreover, sectors like food and beverage, where hygiene and reliability are paramount, benefit significantly from advanced radial ball bearings designed to withstand harsh cleaning processes and contaminants. In the renewable energy sector, especially wind energy, these bearings enable turbines to operate efficiently, thereby enhancing energy production rates.

Tip: Regular maintenance and lubrication of radial ball bearings can significantly contribute to performance stability and durability, making it crucial to incorporate a maintenance schedule tailored to your operational needs.

Maintenance Tips for Extending the Lifespan of Radial Ball Bearings

To extend the lifespan of radial ball bearings in industrial applications, regular maintenance and proper handling are crucial. One of the foremost maintenance tips is to ensure that bearings are kept clean and free from contaminants. Dirt, dust, and moisture can lead to premature wear and tear, impeding performance. Implementing a routine cleaning schedule that includes inspecting seals and shields can significantly enhance bearing longevity.

Furthermore, lubrication plays a vital role in the smooth operation of radial ball bearings. Choosing the appropriate type and amount of lubricant reduces friction and heat buildup, which are common causes of bearing failure. It's essential to periodically check the lubrication levels and replace or replenish as necessary. Additionally, monitoring the operating conditions, such as temperature and load, can help identify any abnormal wear patterns, enabling proactive maintenance before issues escalate. By following these maintenance tips, users can ensure their radial ball bearings perform efficiently and last longer in demanding industrial environments.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Radial ball bearings play a crucial role in enhancing industrial performance by providing reliable solutions for rotating machinery. Their design comprises rolling elements positioned between inner and outer rings, which significantly reduces friction and supports efficient operation. Key features contributing to their industrial efficiency include high load-carrying capacity, low frictional resistance, and durability under various operating conditions. These attributes make them suitable for a wide range of applications, from automotive to heavy machinery.

Radial ball bearings play a crucial role in enhancing industrial performance by providing reliable solutions for rotating machinery. Their design comprises rolling elements positioned between inner and outer rings, which significantly reduces friction and supports efficient operation. Key features contributing to their industrial efficiency include high load-carrying capacity, low frictional resistance, and durability under various operating conditions. These attributes make them suitable for a wide range of applications, from automotive to heavy machinery.