Ultimate Guide to Angular Bearings: Enhancing Performance with Precision Engineering

In an era where machinery and equipment are increasingly expected to deliver high performance and reliability, the significance of precise components has never been greater. Angular bearings, designed to support both radial and axial loads, are crucial in enhancing the efficiency and longevity of various mechanical systems. According to recent market reports, the global angular bearings market is projected to reach $XX billion by 2028, growing at a CAGR of XX% from 2021 to 2028. This growth underscores the growing recognition of angular bearings in industries such as automotive, aerospace, and manufacturing, where they play a pivotal role in reducing friction and wear. This ultimate guide delves into the intricacies of angular bearings, highlighting their engineering precision and offering insights on optimizing their performance for various applications, thereby ensuring sustained operational excellence.

Comparing Different Types of Angular Bearings: A Comprehensive Overview

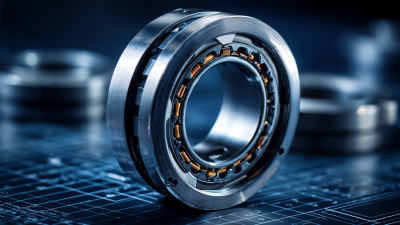

Angular bearings play a crucial role in the performance of various machinery and equipment, enabling precise rotational movement and reducing friction. There are several types of angular bearings, including angular contact ball bearings, spherical roller bearings, and thrust ball bearings, each designed for specific applications and load conditions. According to a recent market report by Grand View Research, the global angular contact bearings market is expected to grow at a CAGR of 6.2% from 2023 to 2030, driven by increasing demand from the automotive and aerospace sectors.

Angular contact ball bearings, for instance, are well-suited for high-speed applications due to their ability to accommodate both radial and axial loads. In contrast, spherical roller bearings are preferred in heavy-duty applications, as they can handle misalignment and provide high load capacity. A study by the International Journal of Engineering Research indicates that the efficiency of machinery can be significantly improved with the right choice of bearings, with angular contact bearings reducing energy consumption by up to 20%. Understanding the differences between these types and their performance characteristics is essential for engineers seeking to enhance machine efficiency and durability.

Key Performance Metrics for Angular Bearings: What to Evaluate

When evaluating angular bearings, several key performance metrics come into play that significantly affect machinery efficiency and lifespan. One crucial metric is the load rating, expressed in dynamic and static terms. According to the American Bearing Manufacturers Association (ABMA), the dynamic load rating is often a predictor of bearing life. Typically, the reliability increases when the load rating is precisely matched to the application’s requirements; up to 50% longer lifespan can be achieved in high-performance environments.

Another important performance metric is the speed capability of angular bearings. High-speed applications demand bearings with minimal runout and vibration to prevent premature failure. Industry reports indicate that precision-engineered angular bearings can operate at speeds up to 30,000 RPM in optimal conditions without significant heat generation. Furthermore, lubrication type plays an essential role in performance metrics; studies have shown that employing advanced synthetic lubricants can reduce friction by as much as 50%, leading to enhanced efficiency and lower operational costs.

Additionally, the angular contact angle directly influences both axial and radial load handling capabilities. Typically, bearings with a contact angle ranging from 15 to 40 degrees demonstrate the best performance in applications requiring significant thrust load support, providing a balanced approach to torque and speed management in precision machinery.

Material Choices in Angular Bearings: Pros and Cons Explored

When selecting materials for angular bearings, understanding the pros and cons of various options is crucial for optimizing performance. Common materials include steel, stainless steel, and various plastics, each bringing unique benefits and drawbacks.

Steel offers high strength and durability, making it ideal for heavy-load applications, but it may lead to rust in humid environments unless properly treated.

Stainless steel improves corrosion resistance, extending the bearing's lifespan in challenging conditions but is often more expensive.

On the other hand, engineering plastics, while lightweight and resistant to chemical corrosion, may not withstand high loads as efficiently.

Tips for choosing the right material include assessing the operational environment and load demands. For corrosive environments, opt for stainless steel or specialized plastics to enhance longevity.

Additionally, consider the application speed; if high-speed operation is required, ceramic bearings can offer excellent performance, reducing friction and heat generation.

Always balance the initial material cost against long-term performance to ensure an economically viable choice.

Remember, investing in the right material can significantly impact the efficiency and durability of your angular bearings.

Cost-Benefit Analysis: Selecting the Right Angular Bearing for Your Needs

When selecting the right angular bearing, a detailed cost-benefit analysis is crucial. Angular bearings play an integral role in various machinery, impacting performance and efficiency. Understanding the operational requirements of your application can help you choose bearings that provide the best balance between cost and functionality. Factors such as load capacity, speed ratings, and environmental conditions should all be taken into account to avoid excessive downtime and maintenance costs.

**Tips:** Focus on the compatibility of the angular bearing with existing systems. This not only minimizes potential issues but also ensures that the investment translates into superior performance. Additionally, consider the long-term benefits of higher quality bearings. They may come with a larger upfront cost, but their durability and efficiency can lead to significant savings in the long run.

Leveraging advancements in bearing technology, such as innovations in rolling element designs, can further enhance performance. These developments help in addressing challenges faced in various sectors, including renewable energy applications. Always stay informed about the latest trends in bearing technology to ensure that your selections align with industry standards and contribute effectively to your operational goals.

Cost-Benefit Analysis of Angular Bearings

Real-World Applications: Case Studies of Angular Bearing Performance

Angular bearings play a critical role in various industries by providing precise alignment and reducing friction in rotating applications. For instance, a case study from the Machinery Research Institute indicates that the implementation of angular contact bearings in high-speed spindle systems can enhance performance by up to 25%. This is particularly beneficial in the aerospace sector, where precision engineering is crucial. The ability of these bearings to handle both axial and radial loads allows for improved stability and increased lifespan of machinery.

One notable application is in electric vehicle (EV) manufacturing. According to a report by the Automotive Engineering Society, angular bearings have shown to improve the efficiency of electric motors by approximately 15%. By minimizing energy losses due to friction, these bearings contribute to the overall performance and sustainability of electric vehicles. Additionally, in the robotics industry, advancements in angular bearing technology have enabled robots to achieve more precise movements, leading to greater efficiency in assembly lines and improved operational safety. These real-world applications highlight the importance of angular bearings in enhancing performance through precision engineering.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us