Why Understanding Industrial Turntable Bearings is Essential for Your Manufacturing Success

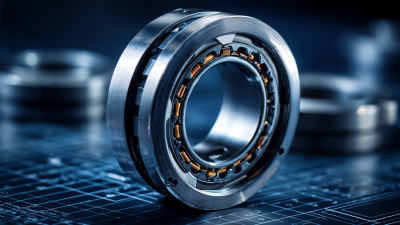

In the realm of modern manufacturing, the significance of the Industrial Turntable Bearing cannot be overstated. As pivotal components that facilitate smooth rotational movement and enhance operational efficiency, these bearings play a crucial role in various applications, from heavy machinery to precision equipment. Understanding the intricacies of Industrial Turntable Bearings is essential for manufacturers aiming to optimize their processes and maintain a competitive edge. This article delves into the fundamental aspects of these bearings, discussing their design, selection criteria, and maintenance strategies. By grasping the importance of Industrial Turntable Bearings, businesses can not only improve their production capabilities but also extend the lifespan of their equipment, thereby ensuring sustainable success in an ever-evolving industry.

The Role of Industrial Turntable Bearings in Enhancing Equipment Efficiency

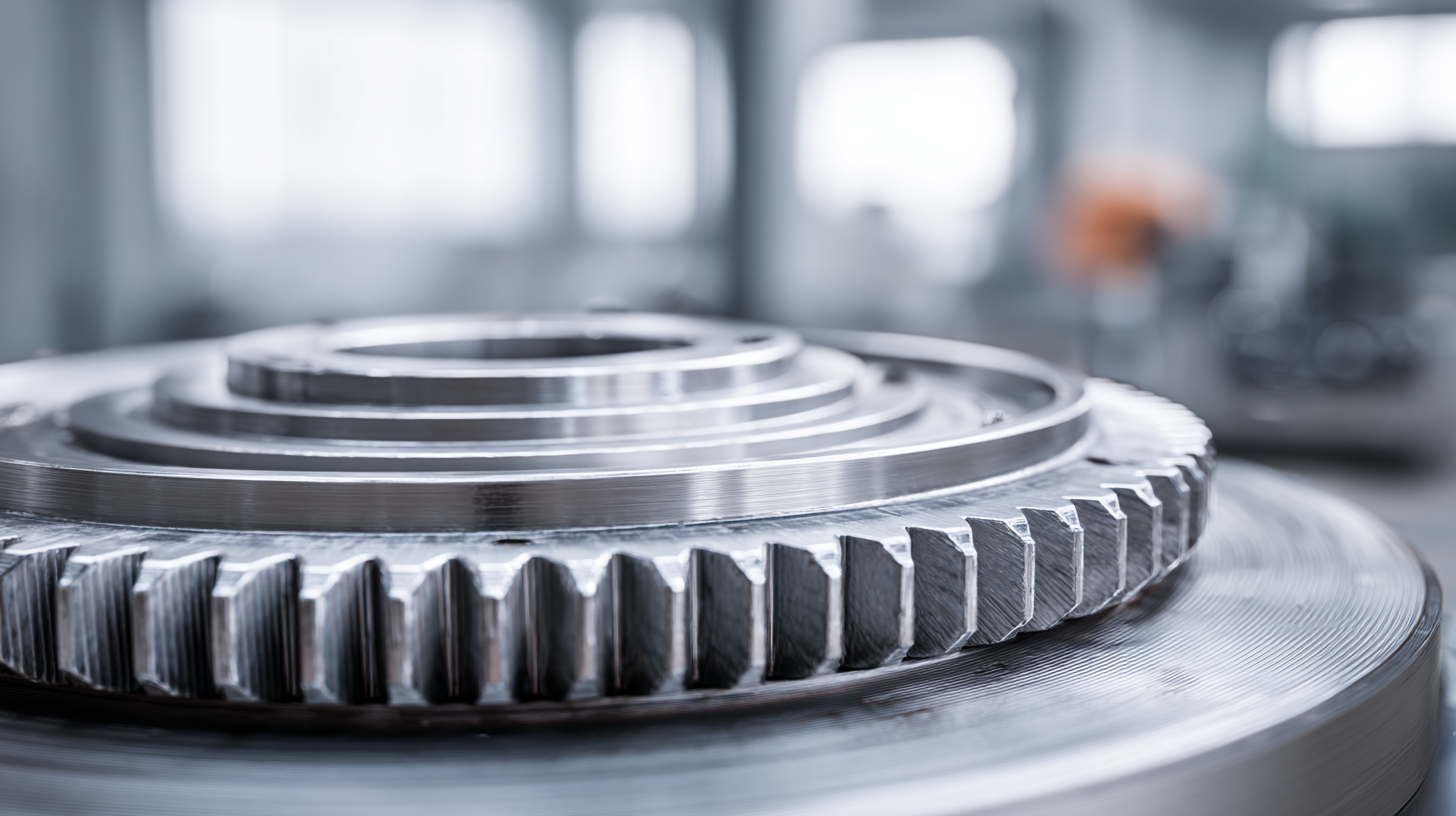

Industrial turntable bearings play a crucial role in enhancing the efficiency of manufacturing equipment. These specialized bearings support heavy loads and allow for smooth rotation, which is essential in many industrial applications. When machinery operates seamlessly, productivity increases, downtime is minimized, and overall operational costs are reduced. By ensuring that turntable bearings are properly maintained, manufacturers can significantly elevate their equipment's performance and lifespan.

**Tips:** Regularly inspect turntable bearings for signs of wear and tear. Lubrication is key; utilize the manufacturer’s recommended lubricant to maintain optimal function. Additionally, keep an eye on alignment to prevent undue stress that can lead to early failure.

Moreover, choosing the right type of turntable bearing is vital. There are various designs available, each tailored for specific applications. Factors such as load capacity, rotational speed, and environmental conditions must be considered when selecting bearings for any machinery. Understanding these elements ensures that manufacturers can optimize their operations, leading to enhanced efficiency and reduced production delays.

**Tips:** Consult with bearing experts during the selection process to ensure that your equipment is equipped with the most appropriate bearing type. Always consider future expansion needs, as this can influence your bearing choice for long-term success.

Key Factors to Consider When Choosing Industrial Turntable Bearings

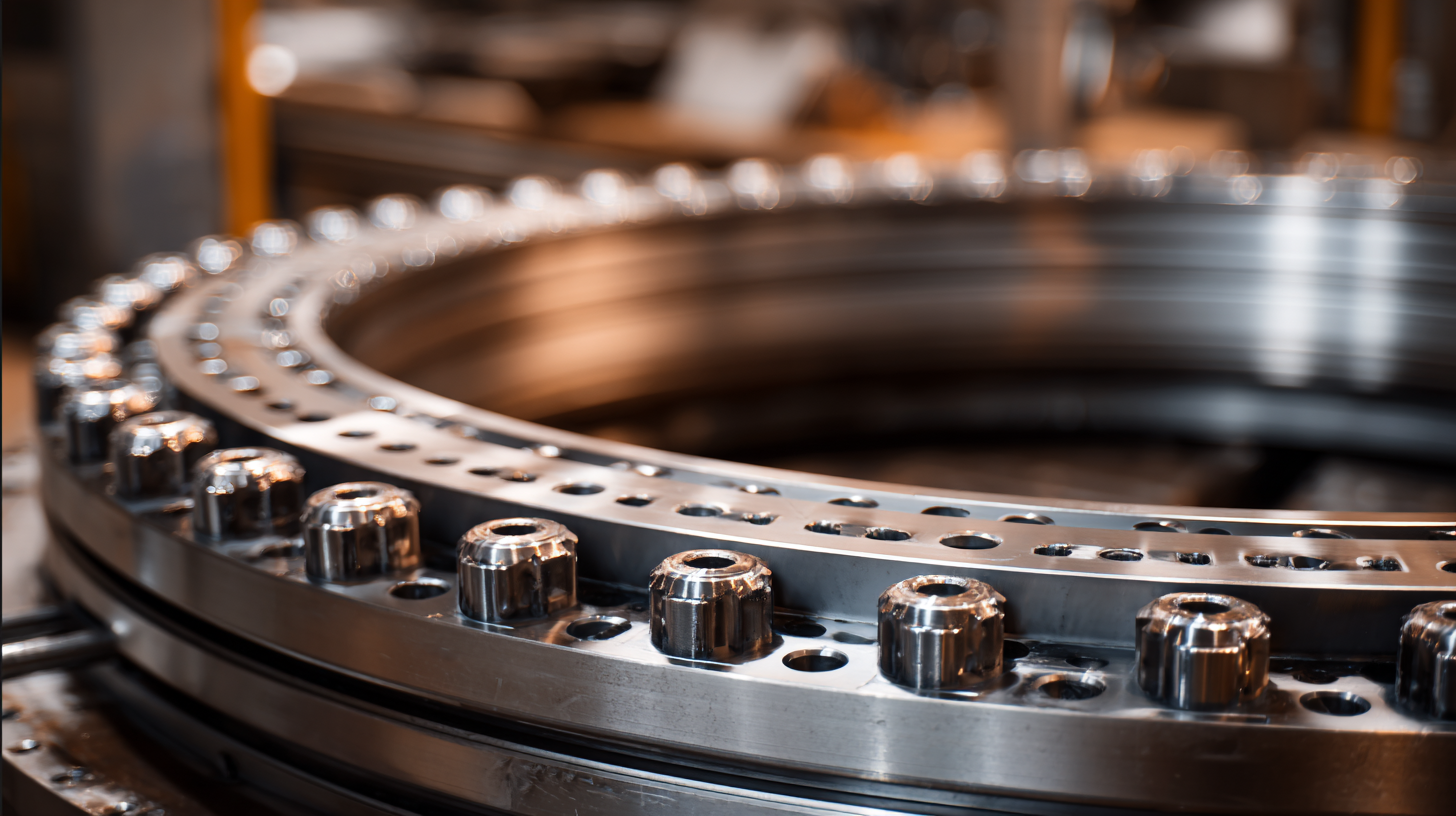

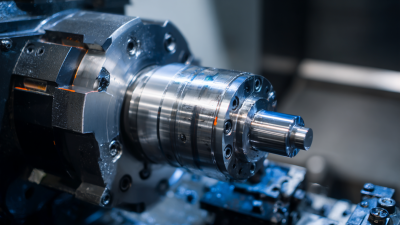

When selecting industrial turntable bearings, several key factors must be considered to ensure optimal performance and longevity in manufacturing applications. Firstly, load capacity is crucial. According to a report by the American Bearing Manufacturers Association, turntable bearings can carry loads ranging from a few hundred pounds to thousands, depending on their size and design. It is essential to calculate the expected loads in your application to choose the right bearing with the appropriate load rating.

Another factor to consider is the bearing's environmental resistance. For instance, if the turntable is used in a facility prone to high humidity or corrosive substances, selecting bearings with protective seals and materials designed for harsh conditions is vital. A study published in the Journal of Manufacturing Science highlights that the right material choices can improve bearing life by up to 50%.

**Tip:** Always consult with bearing manufacturers to ensure that you choose the right specification for your specific needs.

Moreover, the speed of operation should also influence your selection. Bearings are engineered for different speeds, and exceeding these limits can lead to premature failure. Being aware of these specifications can guide you to a more reliable and efficient selection.

**Tip:** Refer to the manufacturer’s catalog for detailed speed ratings and optimal applications to enhance your bearing performance.

Common Challenges in Turntable Bearing Management and Their Solutions

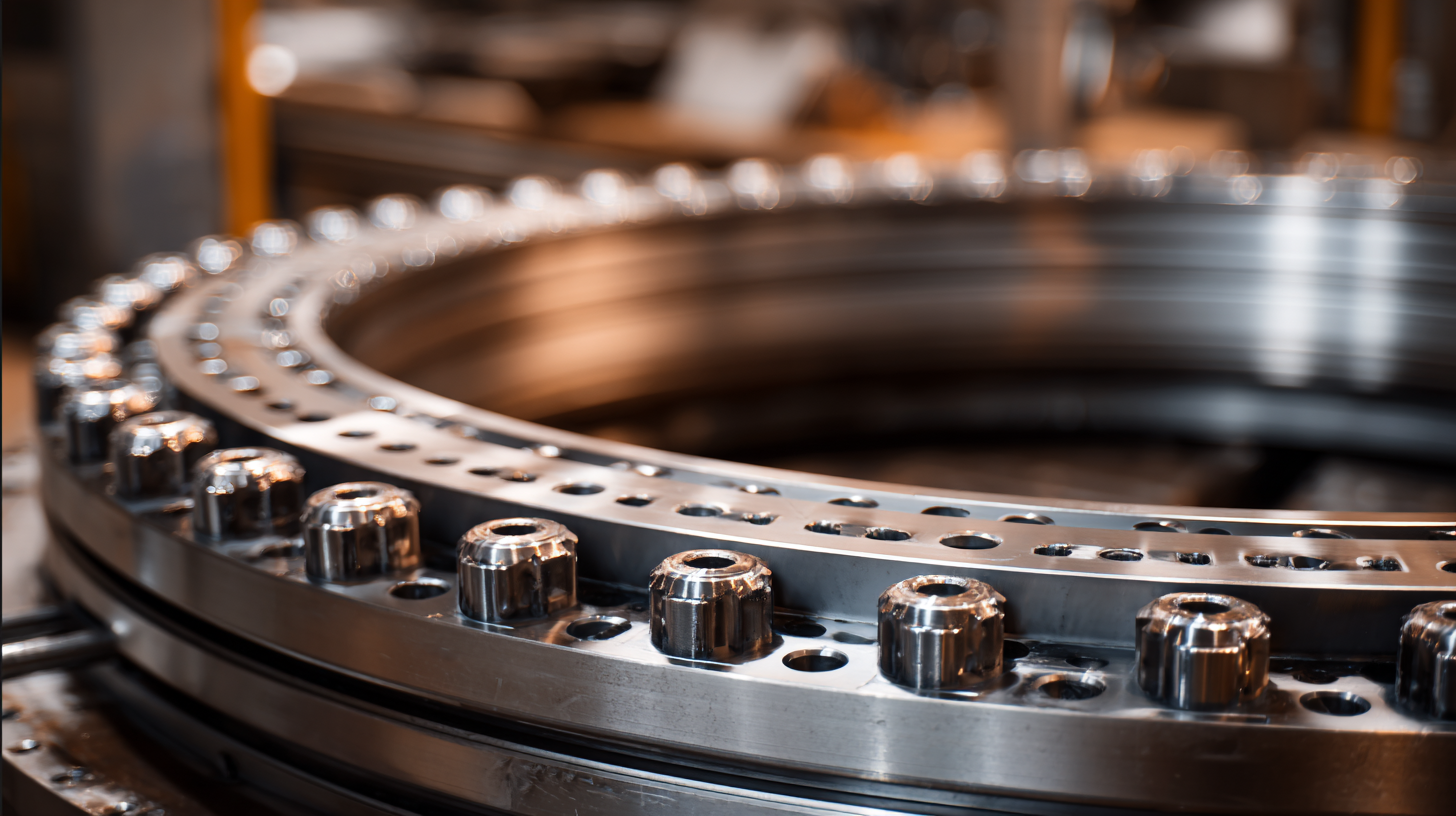

When managing industrial turntable bearings, several common challenges can arise that may hinder manufacturing efficiency. One major issue is premature wear and tear, often caused by inadequate lubrication or contamination. Regular maintenance schedules and the use of high-quality lubricants can significantly mitigate this problem, ensuring the bearings operate smoothly over longer periods. Implementing predictive maintenance techniques can also help identify wear patterns before they lead to failure.

Another challenge is the misalignment of bearings, which can lead to excessive stress and ultimately reduce the lifespan of the equipment. Implementing precise installation procedures and alignment checks can help prevent these issues. Additionally, monitoring the operational environment and ensuring it remains within specified limits can minimize the risks associated with extreme temperature or humidity variations. By addressing these challenges with the right strategies, manufacturers can enhance the reliability of their turntable bearings and ensure smoother operations.

Impact of Turntable Bearing Quality on Manufacturing Output and Safety

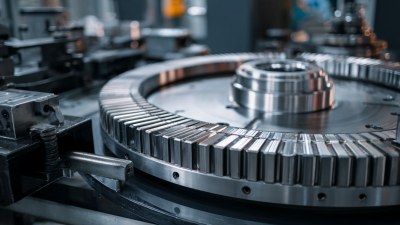

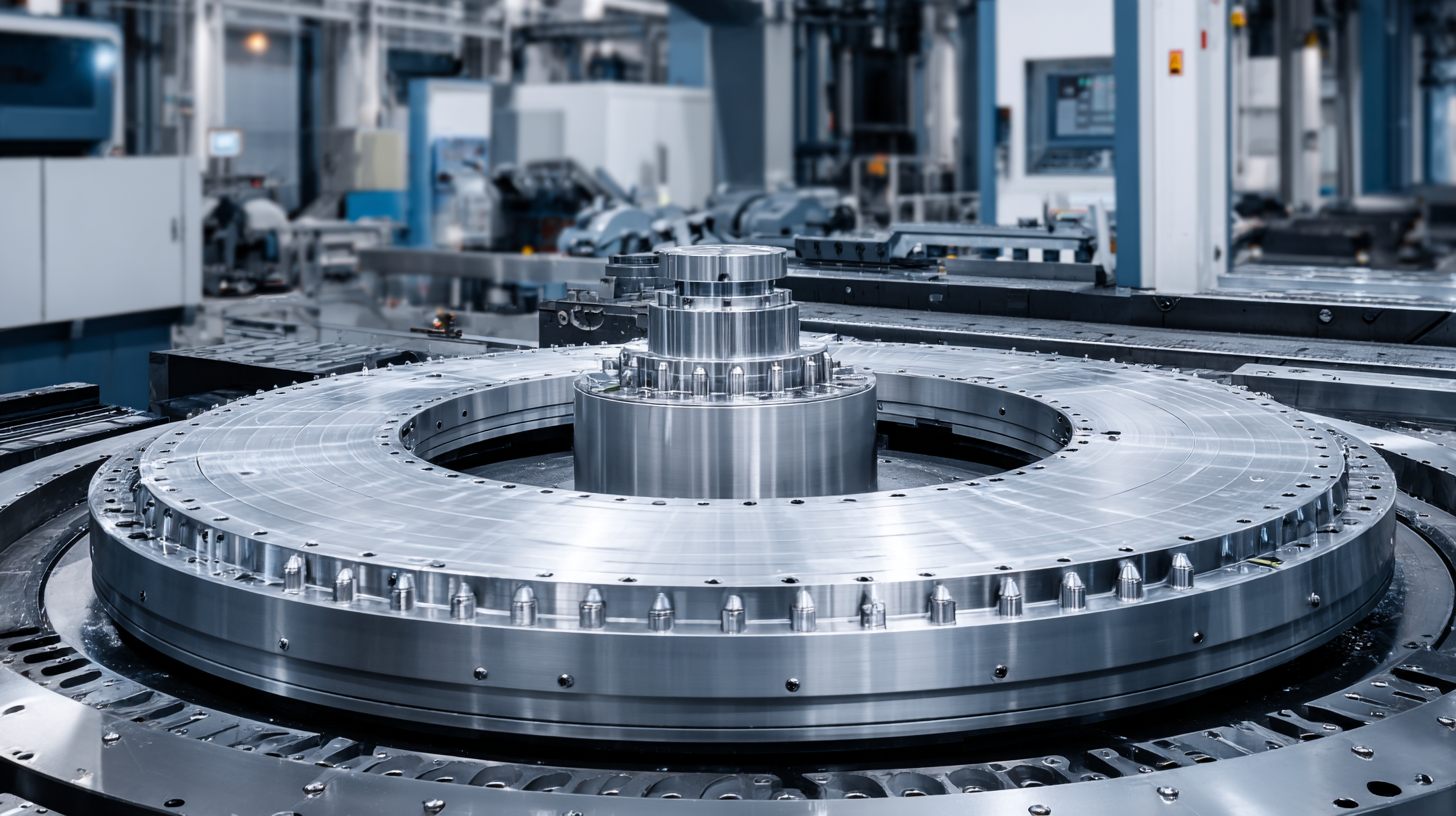

The quality of turntable bearings significantly impacts both manufacturing output and safety in industrial operations. According to a report by the International Journal of Advanced Manufacturing Technology, high-quality bearings can increase machinery efficiency by up to 30%. This efficiency translates into higher production rates and reduced downtime for maintenance. When turntable bearings fail, the costs can be staggering; industry estimates suggest that unplanned downtime can cost manufacturers an average of $260,000 per hour, highlighting the necessity of reliable bearing components.

Moreover, the safety implications of subpar turntable bearings cannot be overlooked. The American National Standards Institute (ANSI) emphasizes that equipment failure related to inadequate bearing quality is one of the leading causes of workplace accidents in manufacturing environments. Investing in high-quality turntable bearings not only ensures smoother operations but also helps safeguard worker safety, reducing the potential for serious injuries and related liabilities. Manufacturers must prioritize these components to maintain operational integrity and foster a culture of safety.

Why Understanding Industrial Turntable Bearings is Essential for Your Manufacturing Success

| Parameter |

Impact on Manufacturing Output |

Impact on Safety |

Key Indicators |

| Bearing Material Quality |

High-quality materials enhance resistance to wear, increasing lifespan and production efficiency. |

Reduces risk of bearing failure, leading to fewer accidents and downtime. |

Durability under stress, maintenance intervals |

| Precision Engineering |

Accurate dimensions lead to better performance and reduced friction, boosting productivity. |

Improves stability and reduces the risk of equipment malfunctions. |

Tolerances, alignment tests |

| Lubrication System |

Proper lubrication minimizes friction, leading to efficient operations and longer bearing life. |

Helps prevent overheating and minimizes failure risks. |

Lubricant viscosity, frequency of application |

| Load Capacity |

Higher load capacity bearings support greater operational loads, enhancing output capabilities. |

Reduces the likelihood of failures under heavy loads, boosting safety. |

Load ratings, operational limits |

| Response to Environmental Conditions |

Bearings designed for specific environments ensure reliability, increasing output reliability. |

Ensures safety against potential environmental hazards. |

Corrosion resistance, temperature tolerance |

Maintenance Best Practices for Optimal Turntable Bearing Performance

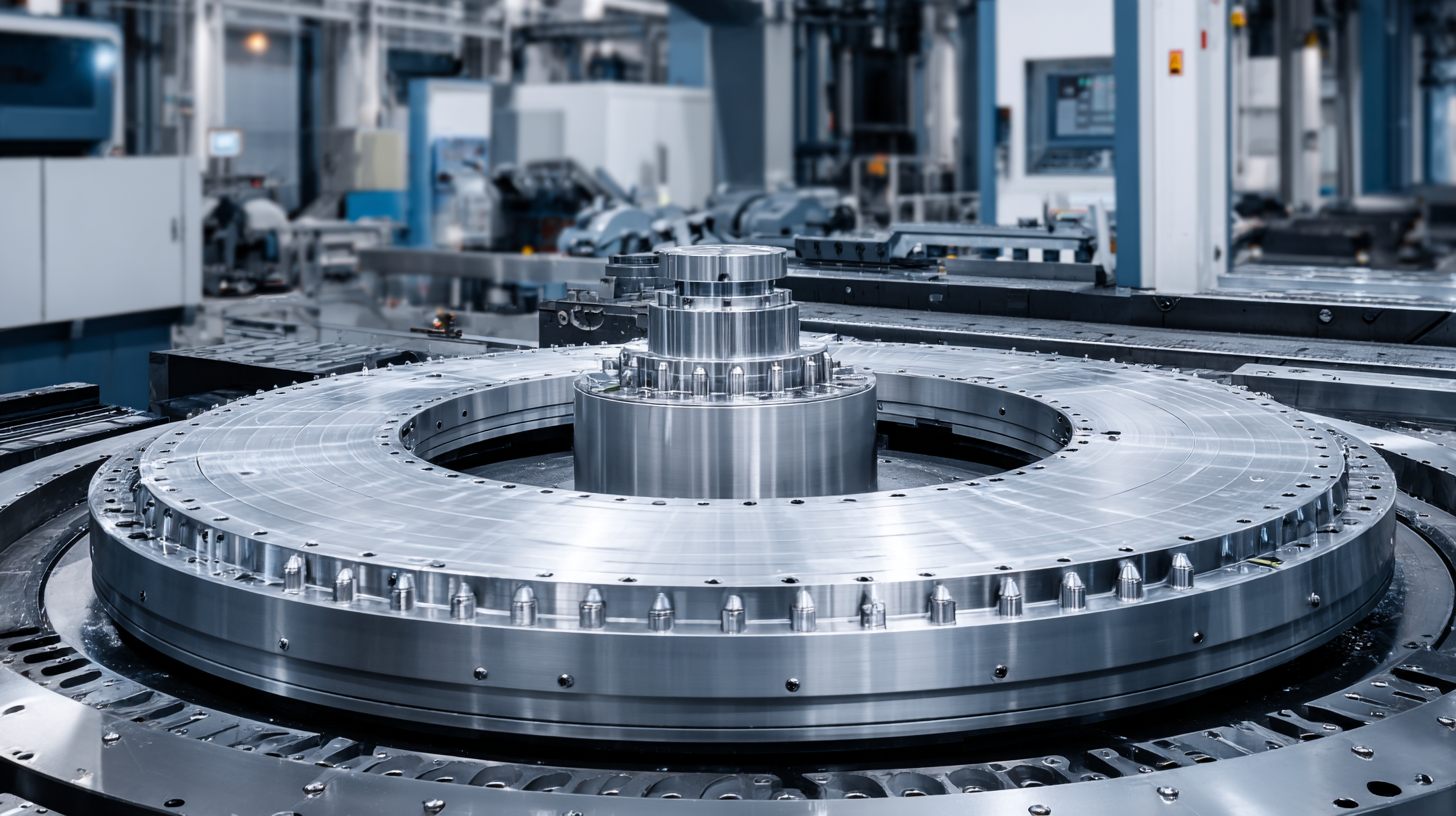

Maintaining optimal performance of industrial turntable bearings is crucial for manufacturing success. According to recent studies, only 38% of U.S. manufacturers are effectively implementing Total Productive Maintenance (TPM) strategies, highlighting a significant opportunity for improvement in maintenance culture. Effective maintenance practices for turntable bearings can reduce unforeseen downtime and extend the lifespan of equipment, ultimately contributing to more reliable manufacturing operations.

To maximize bearing performance, it is essential to adopt best practices surrounding lubrication and contamination management. Air and water can severely compromise lubrication systems, leading to unexpected failures. A robust integrated Asset Performance Management (APM) approach can help organizations monitor asset health, considering factors such as operational conditions and maintenance strategy compliance. This comprehensive view allows manufacturers to proactively address potential issues before they escalate, fostering a culture of reliability and efficiency in manufacturing processes. By focusing on these best practices, manufacturers can enhance turntable bearing performance and ensure sustainable operations.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us