Unlocking the Secrets of Bearing Tools: Essential Guide for DIY Enthusiasts

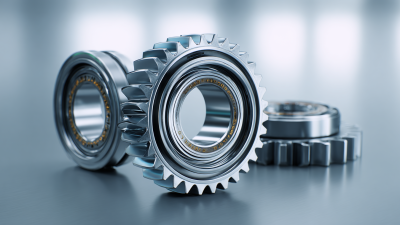

In the realm of DIY projects, understanding and effectively utilizing Bearing Tools can significantly enhance the efficiency and success of your endeavors. These essential instruments are often overlooked yet play a pivotal role in ensuring smooth operation for various mechanical applications, from bicycles to home appliances. This guide aims to demystify the world of Bearing Tools, offering insights into their types, functions, and the best practices for their use. Whether you are a seasoned handyman or a novice enthusiast, mastering these tools will empower you to tackle a range of projects with confidence. Join us as we unlock the secrets of Bearing Tools and equip you with the knowledge needed to elevate your DIY skills to new heights.

Understanding the Different Types of Bearing Tools for DIY Projects

When embarking on DIY projects, understanding the different types of bearing tools is crucial for ensuring that your efforts pay off with precision and durability. According to a report by the European Bearing Manufacturers Association, over 90% of machinery failures can be attributed to improper bearing installation or selection. This highlights the importance of having the right tools at your disposal to handle various types of bearings effectively.

Bearing tools can be categorized into several types, including bearing pullers, installation tools, and alignment tools. Bearing pullers are essential for removing bearings from their housings without causing damage. A study by MarketsandMarkets indicates that the global market for bearing tools is expected to grow by 6.5% annually, underscoring the increasing awareness among DIY enthusiasts about the importance of using specialized tools. Similarly, installation tools, such as bearing seat tools, ensure that bearings are fitted correctly, which enhances the longevity and performance of the machinery. Choosing the appropriate tools not only leads to successful project outcomes but also contributes to extending the lifespan of the equipment you’re working on.

The Importance of Quality in Bearing Tool Selection

When selecting bearing tools, quality should be at the forefront of every DIY enthusiast's mind. The importance of quality in bearing tool selection can significantly impact not just the efficiency of your projects, but also the longevity and performance of your machinery. Bearing tools play a crucial role in key mechanical systems, such as wheel bearings, which are vital for safe braking and overall vehicle stability. Hence, investing in high-quality bearing tools ensures reliable performance and minimizes the risk of premature failure during critical operations.

Tips for choosing the right bearing tools include researching the materials and design, as well as considering user reviews and expert recommendations. Don't hesitate to compare various brands and models; finding tools that offer sturdiness and precision is essential. Additionally, ensure that the bearing tools you select are compatible with your specific projects, as this will enhance performance and ease of use. As DIY enthusiasts, being well-equipped is fundamental, and understanding the significance of quality will steer you towards making informed and valuable investments in your tool collection.

Essential Features to Look for in Bearing Tools

When selecting bearing tools, DIY enthusiasts should prioritize several essential features to ensure optimal performance and durability. One of the key attributes to consider is the material of the tools. According to a recent industry report by Global Market Insights, tools made from high-quality alloy steel can enhance durability by up to 40%, significantly reducing the wear and tear associated with regular use. This is crucial for ensuring that the tools remain effective over time, especially in demanding applications.

Another critical feature is the precision of the tool's design. High-precision bearing tools are vital for achieving tight tolerances, which can directly affect the performance of assembled machinery. Research by the International Journal of Precision Engineering and Manufacturing indicates that using precision tools can reduce assembly errors by as much as 30%, leading to improved operational efficiency. Additionally, features such as ergonomic handles and non-slip grips can greatly enhance user comfort and control, further contributing to successful DIY projects. Crafting and selecting tools with these characteristics can empower enthusiasts to undertake complex tasks confidently and effectively.

Unlocking the Secrets of Bearing Tools: Essential Guide for DIY Enthusiasts - Essential Features to Look for in Bearing Tools

| Feature |

Description |

Importance |

| Material |

Choose tools made from high-quality steel or durable materials to ensure longevity. |

High |

| Type |

Select the appropriate type of bearing tool depending on your project needs (e.g. pullers, presses). |

Medium |

| Ease of Use |

Look for ergonomic designs that enhance comfort and ease of operation. |

High |

| Precision |

Tools should provide accurate alignment and fitting for effective bearing installation. |

High |

| Portability |

Consider compact and lightweight options for easy transportation and storage. |

Medium |

| Cost |

Find tools that provide good quality at a reasonable price as the cost can vary widely. |

Medium |

| Warranty |

Look for tools that come with a warranty for added protection against defects. |

Low |

Common Uses of Bearing Tools in Home Improvement

Bearing tools play a crucial role in various home improvement projects, proving indispensable for DIY enthusiasts. According to a report by the American National Standards Institute (ANSI), over 60% of home improvement projects involve tasks that require precise bearing installations, emphasizing the importance of having the right tools at hand. These tools facilitate smooth operations in areas ranging from cabinetry and furniture making to the installation of appliances, where bearings ensure components rotate or slide seamlessly.

In addition to their common applications in woodworking and furniture assembly, bearing tools are increasingly utilized in home renovation projects. The Home Improvement Research Institute (HIRI) notes that 40% of homeowners engage in DIY renovations that involve heavy machinery, underscoring the necessity of effective bearing tools for safety and efficiency. Properly installed bearings improve the longevity of appliances and tools, reducing maintenance costs by up to 25% as per the Machinery and Equipment Manufacturers Association (MEMA) report. Investing in high-quality bearing tools not only enhances the quality of home repairs but also fosters a deeper understanding of mechanical systems among DIY enthusiasts.

Common Uses of Bearing Tools in Home Improvement

Maintenance Tips for Prolonging the Life of Your Bearing Tools

Proper maintenance of your bearing tools is essential to ensure they function effectively over time. Regularly clean your tools to remove dust, debris, and harmful contaminants. Use a soft brush or cloth to wipe down surfaces, and avoid using corrosive cleaners that could damage the finish.

Additionally, keeping your tools lubricated is crucial. Apply the right type of lubricant to the moving parts periodically to minimize friction, reducing wear and tear.

Proper maintenance of your bearing tools is essential to ensure they function effectively over time. Regularly clean your tools to remove dust, debris, and harmful contaminants. Use a soft brush or cloth to wipe down surfaces, and avoid using corrosive cleaners that could damage the finish.

Additionally, keeping your tools lubricated is crucial. Apply the right type of lubricant to the moving parts periodically to minimize friction, reducing wear and tear.

Another important tip for prolonging the life of your bearing tools is to store them correctly. Always keep your tools in a dry, cool space away from direct sunlight. Using a designated toolbox can prevent accidental damage and keep your tools organized.

Furthermore, make sure to check for signs of rust or corrosion regularly. If you spot any issues, address them immediately to prevent further deterioration.

Implementing these maintenance tips can significantly extend the lifespan and performance of your bearing tools, making your DIY projects more efficient and enjoyable.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Proper maintenance of your bearing tools is essential to ensure they function effectively over time. Regularly clean your tools to remove dust, debris, and harmful contaminants. Use a soft brush or cloth to wipe down surfaces, and avoid using corrosive cleaners that could damage the finish.

Additionally, keeping your tools

Proper maintenance of your bearing tools is essential to ensure they function effectively over time. Regularly clean your tools to remove dust, debris, and harmful contaminants. Use a soft brush or cloth to wipe down surfaces, and avoid using corrosive cleaners that could damage the finish.

Additionally, keeping your tools