GNE50-KRR-B Radial insert ball bearing

product description

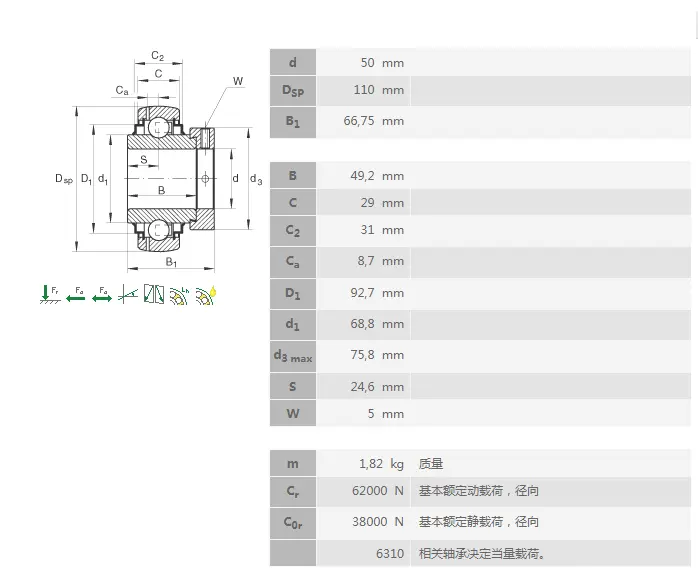

The dimensions of the bearing model GNE50-KRR-B are as follows:

• Inner diameter (d): 50 mm

• Outer diameter (D): 110 mm

• Width (B1): 66.75 mm

• Total width (B4): 49.2 mm

• Inner diameter chamfer height (Ca): 8.7 mm

• External diameter chamfer height (D1): 92.7 mm

• Inner diameter (d1): 68.8 mm

• Maximum internal diameter chamfer size (d3): 75.8 mm

• Width (S): 24.6 mm

• Thickness (W): 5 mm

• Quality (m): 1.82 kg

• Basic rated dynamic load (C): 66,000 N (radial)

• Basic rated static load (Cor): 38,000 N (radial)

• Fatigue ultimate load (Cur): 19,700 N (radial)

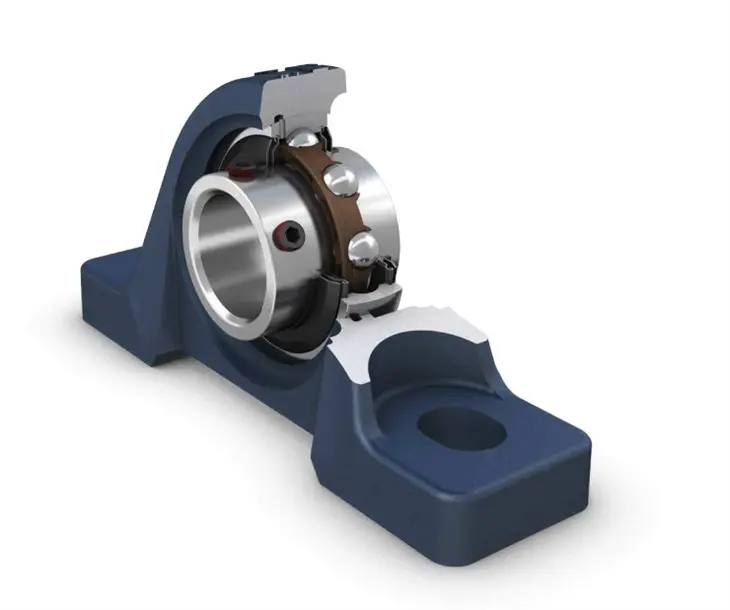

GNE50-KRR-B bearings are INA brand of external spherical bearings with eccentric sleeve and lip seal (KRR) structure. This type of bearing is commonly used in industrial equipment scenarios requiring high precision positioning and corrosion resistance, such as:

metallurgical equipment

Such as rolling mills, blast furnaces, etc., which are used to bear heavy loads and vibrations, while preventing grease leakage or external pollutants from invading.

mining machine

In mining equipment, it is used for shaft adjustment and sealing, adapting to harsh dust and wet environment.

matters need attention:

Ensure the precision of the eccentric sleeve and shaft during installation to avoid bearing deformation caused by excessive tightening.

The sealing ring (KRR) should be checked regularly to prevent failure due to high temperature or aging.